Improved hot wall correction method considering hypersonic chemical non-equilibrium effect

A hypersonic, non-equilibrium technology, used in chemical process analysis/design, design optimization/simulation, special data processing applications, etc., can solve the problem of not considering the influence of chemical non-equilibrium effects, and achieve high computational efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

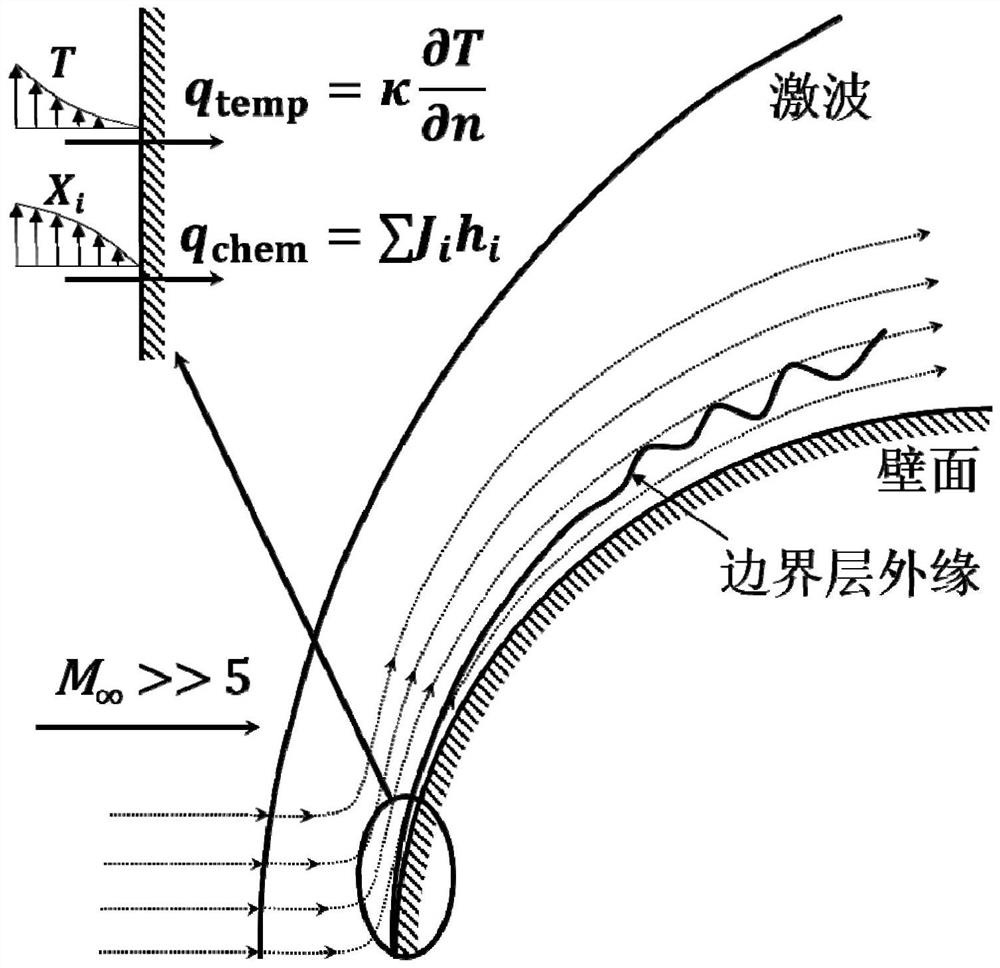

[0030] The present invention provides an improved thermal wall correction method considering hypersonic chemical non-equilibrium effects, which is applicable to physical problems such as figure 1 shown.

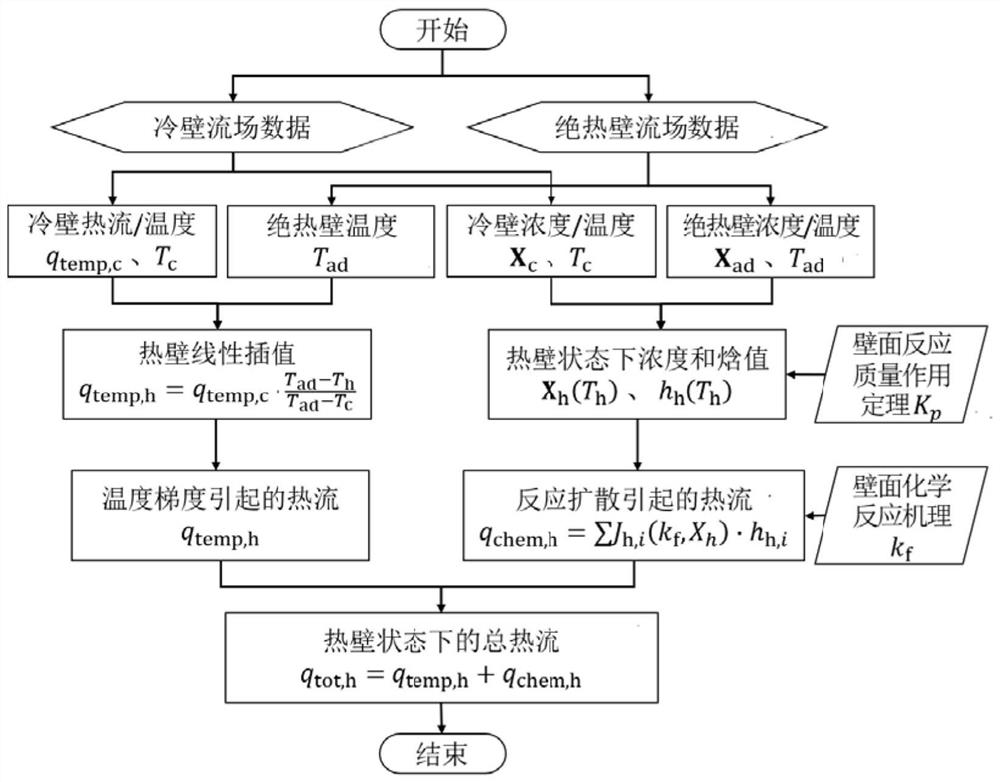

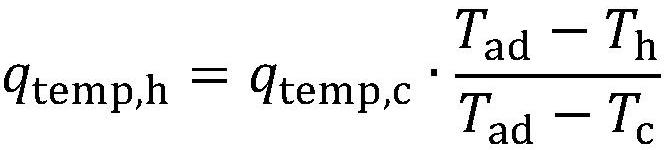

[0031] The improved hot wall correction method of the present invention is developed based on the influence law of high temperature chemical effects of the wall surface on the heat flow of the wall surface and the linearity of the wall surface temperature. The study on the chemical non-equilibrium effect shows that although the linearity between the convective heat flow caused by reaction diffusion and the wall temperature becomes worse, the convective heat flow caused by the temperature gradient and the wall temperature still maintain a high linearity. Therefore, the convective heat flow can be decomposed according to the contribution of the physical process. The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com