Calender for PVC film production

A PVC film, calender technology, applied in the direction of applications, household appliances, other household appliances, etc., to achieve the effect of avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

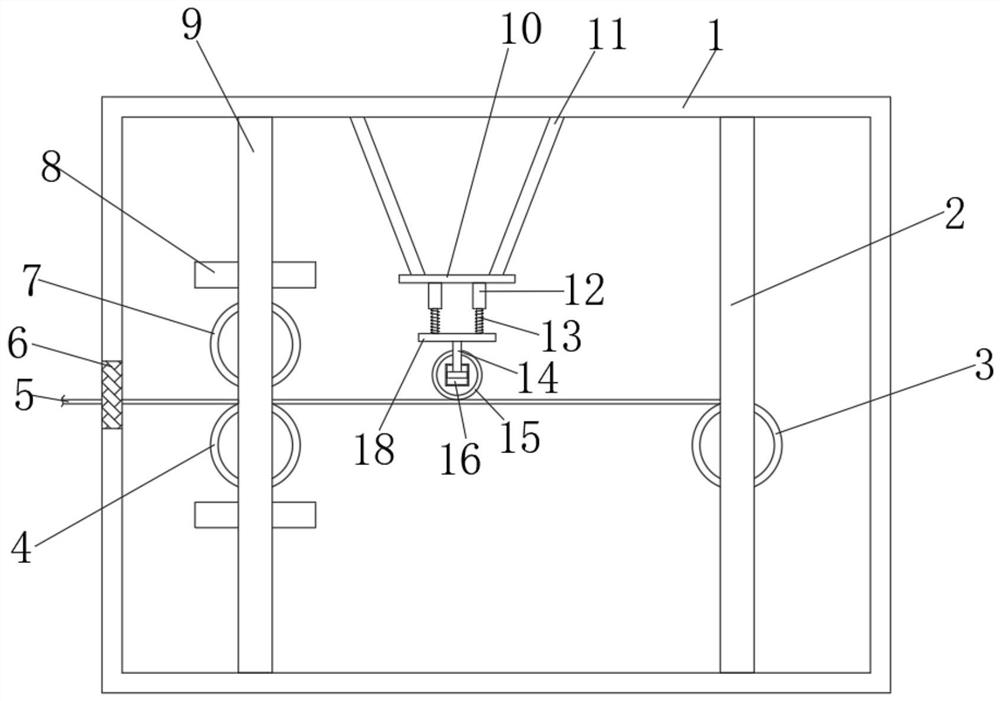

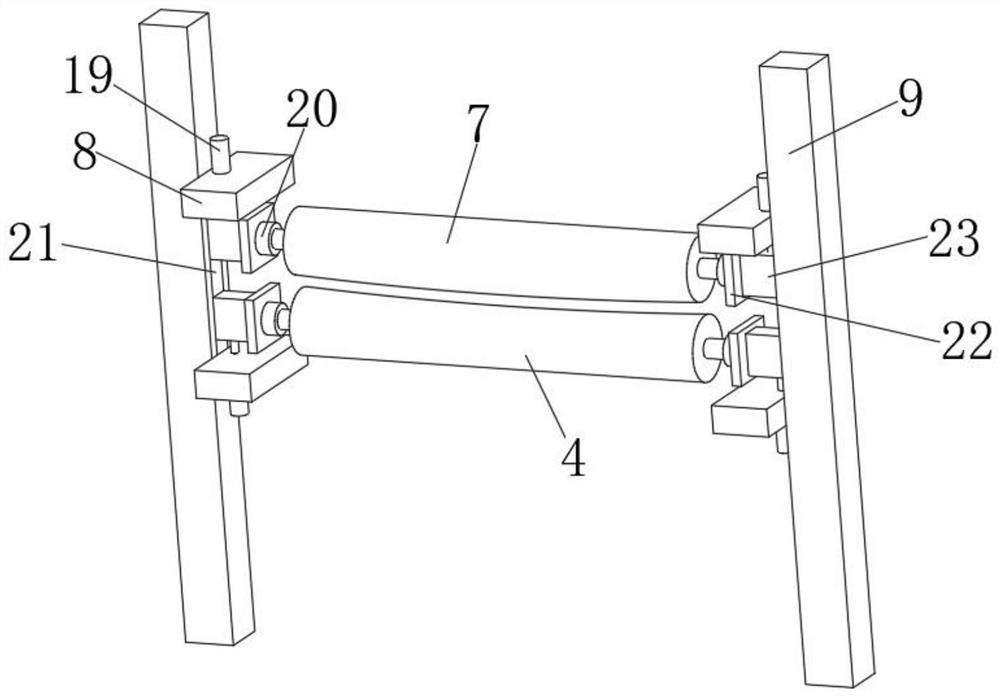

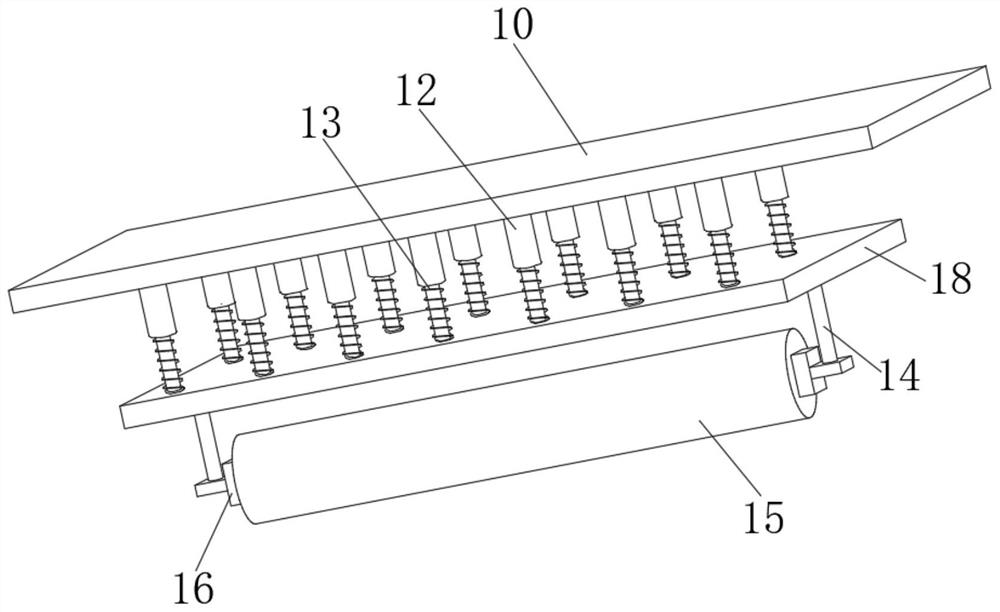

[0028] refer to Figure 1-3 , a calender for PVC film production, comprising a box body 1, the top and bottom inner walls of the box body 1 are connected with a second fixed rod 9 by bolts, and one side outer wall of the second fixed rod 9 is connected with a first fixed rod by bolts. Connecting plate 8, the top outer wall of the first connecting plate 8 is plugged with an electric push rod 19, and one end outer wall of the electric push rod 19 is connected with a slider 23 by bolts, and one side outer wall of the second fixed rod 9 has a chute 21 , and the slider 23 forms a sliding connection with the chute 21, the outer wall on one side of the slider 23 is connected with the third connecting plate 22 by bolts, and the outer wall on one side of the third connecting plate 22 is connected with the bearing seat 20 by bolts, the bearing seat The inner wall of one side of 20 is rotatably connected with the second pressure roller 7, and the inner wall of one side of the other beari...

Embodiment 2

[0032] refer to Figure 4-5 , a calender for PVC film production. Compared with Embodiment 1, the outer wall of one side of the box body 1 is connected with a blower 24 by bolts, and the outer wall of one side of the blower 24 is plugged with an air inlet pipe 25. One end of the air duct 25 extends to the inside of the box body 1, the top outer wall of the air inlet duct 25 is plugged with a connecting pipe 26, and one end of the connecting pipe 26 is plugged with an air outlet nozzle 27, and the cross section of the air outlet nozzle 27 is a whistle. type.

[0033] Working principle: when in use, when people are calendering the PVC film, they can start the electric push rod 19, and the electric push rod 19 drives the first pressure roller 4 and the second pressure roller 7 to move relative or opposite to each other, thereby adjusting the PVC film. The magnitude of the pressure can adjust the calendering degree of the PVC film. At the same time, the top cross section of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com