Intelligent batch sample loading system for blood sampling sample tubes

A technology of tube batches and sample tubes, which is applied in the field of intelligent blood collection sample tube batch loading system, can solve the problems that the sample loading unit cannot realize samples and is low, and achieve the goals of reducing the risk of biological contamination, reasonable structure, and improving transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

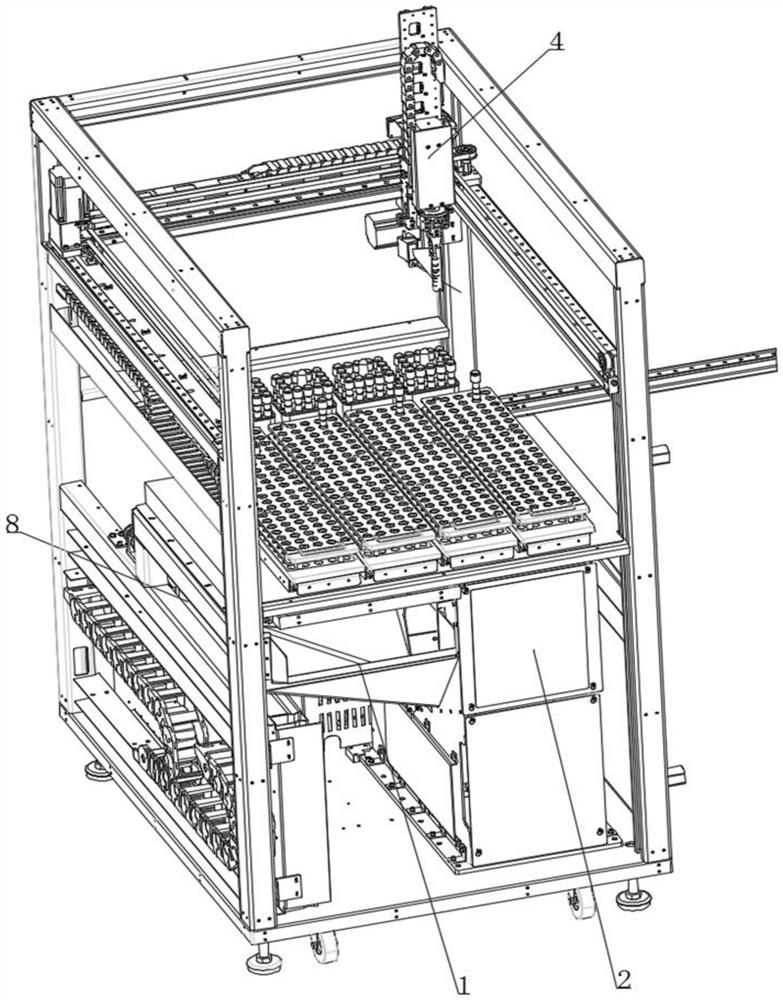

[0038] Such as Figure 1 to Figure 6 As shown, a batch sample loading system for intelligent blood collection sample tubes of the present invention includes a batch sample loading structure 1, a material handling mechanism 2, a sample transfer mechanism 3, and a sample grabbing position 9. The batch sample loading structure 1 is a structure, and the bottom of the batch sample loading structure 1 is connected with the bottom of the side of the material handling mechanism 2; The top of the multi-stage push plate structure in the material mechanism 2 is connected to one end of the sample transfer mechanism 3, and the other end of the sample transfer mechanism 3 is provided with a sample grab position 9; A distribution tray structure 11 is provided, and the distribution tray structure 11 is used to control the sample tubes to move the sample grabbing positions 9 one by one;

[0039] It also includes a sample moving mechanism 4, which is a device that can move freely to grab the s...

Embodiment 2

[0051] Such as Figure 1 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the top of the material sorting mechanism 2 is connected to the sample transfer mechanism 3 through a slope structure, the sample transfer mechanism 3 adopts a conveyor belt structure, and the sample transfer mechanism 3 includes two Timing belt, and an opening 16 along the direction of the timing belt between the two timing belts, the width of the opening 16 is greater than the diameter of the sample tube body, and the width of the opening 16 is smaller than the diameter of the tube cover; When the material distribution tray moves in the direction, it drives the sample tube to maintain a vertical state and hangs on the synchronous belt to move.

[0052] The bottom of the sample grabbing position 9 is provided with a jacking mechanism, and the jacking mechanism is used to lift the sample tube to a certain height, so that the sample tube is separated from the belt, and...

Embodiment 3

[0057] Such as Figure 1 to Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the material handling mechanism 2 includes a housing 20, a loading plate 21, a drive assembly, a pushing assembly, and a fixed support plate assembly, and the loading plate 21, a driving assembly, and a pushing assembly The material component and the fixed support plate component are arranged in the shell 20, and the load plate 21 is installed obliquely downward from the front side of the shell 20, the load plate 21 is connected with the middle and lower part of the bottom of the push material assembly, and fixed supports are provided between the push material components of all levels board assembly;

[0058] The driving assembly drives the pusher assembly to push the blood collection sample tubes, and the blood collection tube sample tubes are output to the outlet of the material sorting mechanism 2 one by one, and then output to the sample transfer mechanism 3 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com