Waste sulfuric acid recovery and concentration process

A technology of waste sulfuric acid and process, which is applied in the direction of sulfur trioxide/sulfuric acid, sulfur compounds, inorganic chemistry, etc., can solve the problems of inability to improve the purity of sulfuric acid, increase the purity of sulfuric acid, and high equipment consumption rate, so as to improve practicability and economy. The effect of reducing production cost and saving the use of sulfuric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

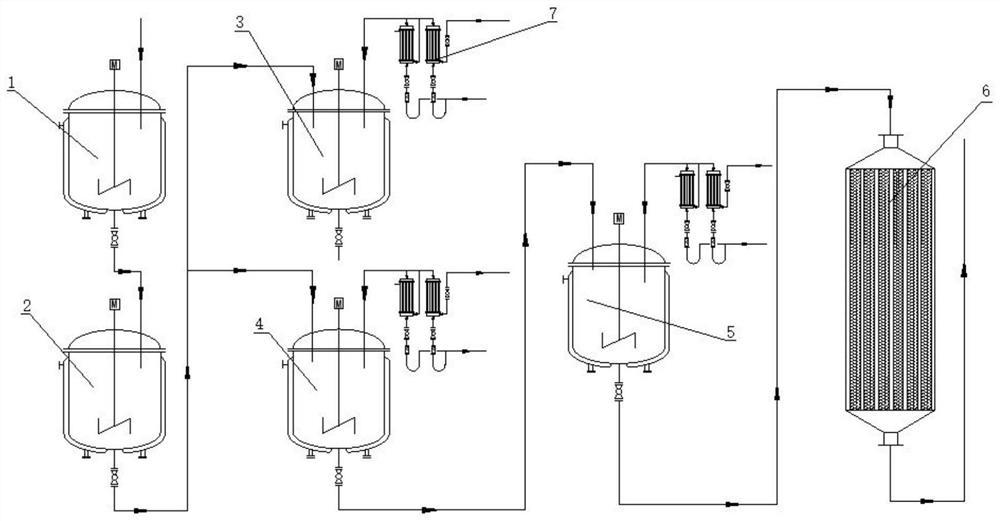

[0027] Such as figure 1 As shown, a waste sulfuric acid recovery and concentration process, the concentration method is based on a recovery and concentration device, the recovery and concentration device includes a filter kettle 1, an extraction kettle 2, a rectification I kettle 3, a rectification II kettle 4, and a vacuum evaporation kettle 5 and cation exchange resin column 6, rectification I kettle 3, rectification II kettle 4 and vacuum evaporation kettle 5 are all connected with double condenser 7;

[0028] The recovery and concentration process of waste sulfuric acid includes the following steps:

[0029] 1). Filtration: transfer the solution containing waste sulfuric acid into filter kettle 1 first, heat up to 80°C, add coconut shell activated carbon to the solution, control the mass percentage of coconut shell activated carbon to 15%, and use 800r / min Stir at a stirring rate of 40 minutes, and let stand at a constant temperature for 30 minutes. First, press filter wi...

Embodiment 2

[0038] The difference between this embodiment and embodiment 1 is:

[0039] A recovery and concentration process of waste sulfuric acid, the recovery and concentration process of waste sulfuric acid comprises the following steps:

[0040] 1). Filtration: transfer the solution containing waste sulfuric acid to filter kettle 1 first, heat up to 50°C, add coconut shell activated carbon to the solution, control the mass percentage of coconut shell activated carbon to 5%, and use 500r / min Stir at a stirring rate for 20 minutes, and let stand at a constant temperature for 10 minutes. First, filter with a microfiltration membrane, then filter with a nanofiltration membrane. Control the air pressure to 0.2Mpa, and collect the filtrate;

[0041] The membrane pore size of the microfiltration membrane is 500nm, and the membrane pore size of the nanofiltration membrane is 50nm;

[0042] 2). Extraction: Transfer the filtrate to the extraction kettle 2, cool down to 20°C, add the extractan...

Embodiment 3

[0049] The difference between this embodiment and embodiment 1, 2 is:

[0050] A recovery and concentration process of waste sulfuric acid, the recovery and concentration process of waste sulfuric acid comprises the following steps:

[0051] 1). Filtration: transfer the solution containing waste sulfuric acid to filter kettle 1 first, heat up to 80°C, add coconut shell activated carbon to the solution, control the mass percentage of coconut shell activated carbon to 5%, and use 800r / min Stir at a stirring rate for 20 minutes, and let stand at a constant temperature for 30 minutes. First, press filter with a microfiltration membrane, then filter with a nanofiltration membrane, control the air pressure to 0.2Mpa, and collect the filtrate;

[0052] The membrane pore size of the microfiltration membrane is 800nm, and the membrane pore size of the nanofiltration membrane is 50nm;

[0053] 2). Extraction: transfer the filtrate to the extraction kettle 2, cool down to 30°C, add the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com