Forming process of hexagonal alloy tool steel s2

A hexagonal alloy and forming process technology, which is applied in the field of tool steel, can solve the problems of affecting the surface hardness of finished products, strong decarburization sensitivity, cumbersome process, etc., and achieve the effects of reducing quenching deformation, prolonging wear resistance, and stabilizing the quenching hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

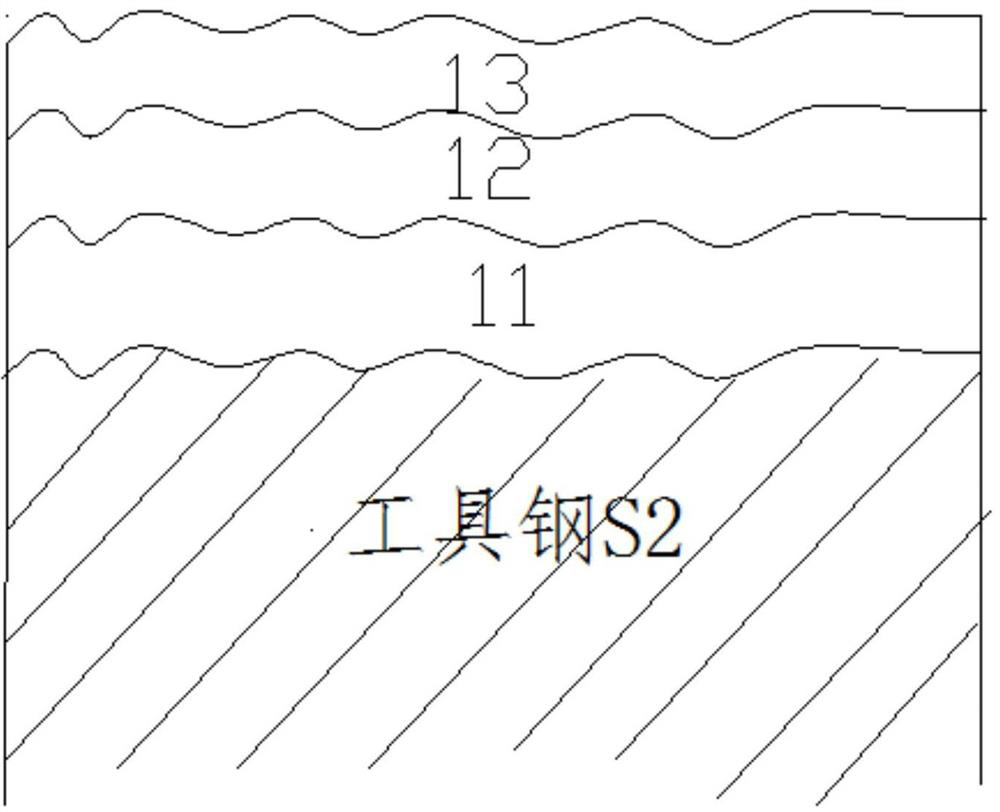

[0086] Step 1: Sand blasting treatment: sandblasting the tool steel S2 with a raw material size of 8 mm, and the sand blasting treatment is used to remove the oxide layer on the surface of the raw material tool steel S2;

[0087] Step 2: Spheroidizing annealing treatment:

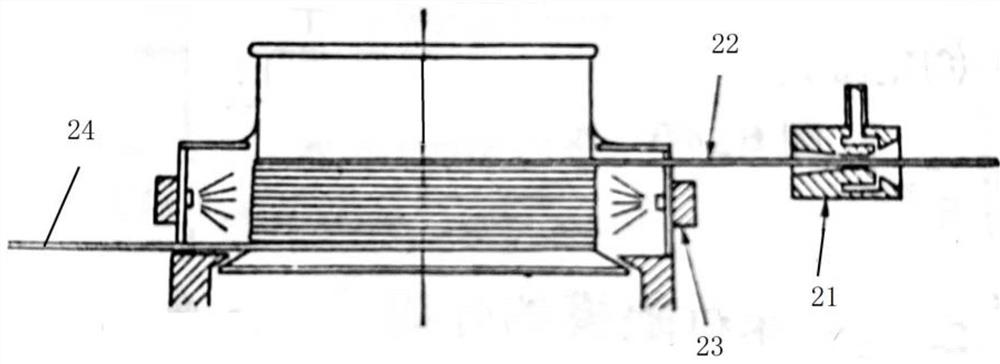

[0088] Two (a): Transport the wire rack loaded with the tool steel S2 after sandblasting to the supporting plate of the base, cover the inner cover, lock the inner cover through hydraulic clamps, and then start filling nitrogen, and load the heating cover ;

[0089] Two (a): Carry out the first stage of temperature rise in the furnace, raise the temperature in the furnace to 593°C, and keep it at 593°C for two hours, use N 2 To purge, N 2 The purging volume is: 80m 2 / h, and replace all the original gas in the furnace;

[0090] Two (c): Carry out the second stage of temperature rise in the furnace, raising the temperature in the furnace from 593°C to 775°C, with a heating rate of 88.5°C / h. During the he...

Embodiment 2

[0096] Step 1: Sand blasting treatment: sandblasting the tool steel S2 with a raw material size of 8 mm, and the sand blasting treatment is used to remove the oxide layer on the surface of the raw material tool steel S2;

[0097] Step 2: Spheroidizing annealing treatment:

[0098] Two (a): Send the tool steel S2 after the blasting treatment into the bell annealing furnace;

[0099] Two (b): Carry out the first stage of temperature rise in the furnace, raise the temperature in the furnace to 596 ° C, and keep it at 596 ° C for two hours, use N 2 To purge, N 2 The purging volume is: 75m 2 / h-85m 2 / h, and replace all the original gas in the furnace;

[0100] Two (c): Carry out the second stage of temperature rise in the furnace, raising the temperature in the furnace from 596°C to 778°C, with a heating rate of 85°C / h, during the heating process, N 2 The purge volume is 65m 2 / h, and maintained at 778°C for four hours, N 2 The purge volume is 55m 2 / h;

[0101] Two (d): ...

Embodiment 3

[0106] Step 1: Sand blasting treatment: sandblasting the tool steel S2 with a raw material size of 8 mm, and the sand blasting treatment is used to remove the oxide layer on the surface of the raw material tool steel S2;

[0107] Step 2: Spheroidizing annealing treatment:

[0108] Two (a): Send the tool steel S2 after the blasting treatment into the bell annealing furnace;

[0109] Two (b): Carry out the first stage of temperature rise in the furnace, raise the temperature in the furnace to 600°C, and keep it at 600°C for two hours, use N 2To purge, N 2 The purging volume is: 85m 2 / h, and replace all the original gas in the furnace;

[0110] Two (c): Carry out the second stage of temperature rise in the furnace, raising the temperature in the furnace from 600°C to 780°C, with a heating rate of 90°C / h. During the heating process, N 2 The purge volume is 75m 2 / h, and maintained at 780°C for four hours, during the heat preservation process, N 2 The purge volume is 65m 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com