Cavity assembly type tunnel inverted arch and construction method

A construction method and prefabricated technology, applied in the direction of tunnels, tunnel linings, shaft equipment, etc., can solve the problems of mud pouring and initial support, construction quality is difficult to guarantee, and rescue speed is slow, so as to ensure the safety of tunnel structure and construction, reduce The effect of small labor and mechanical costs and reducing casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

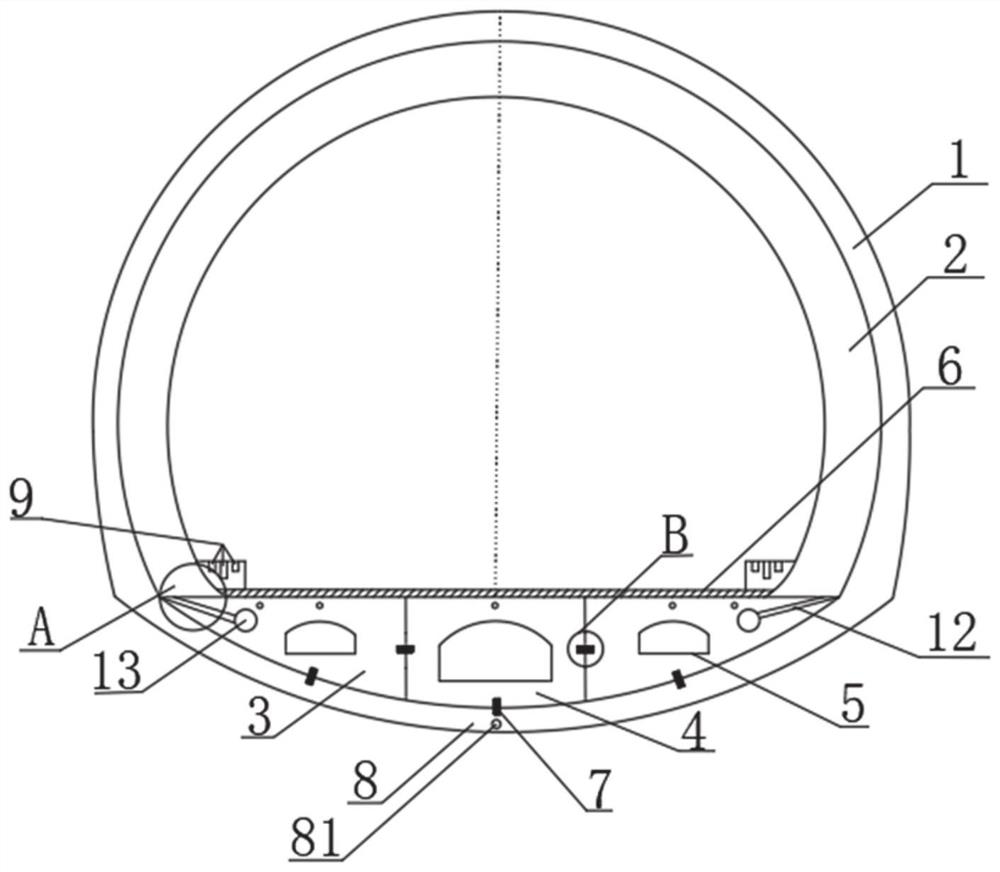

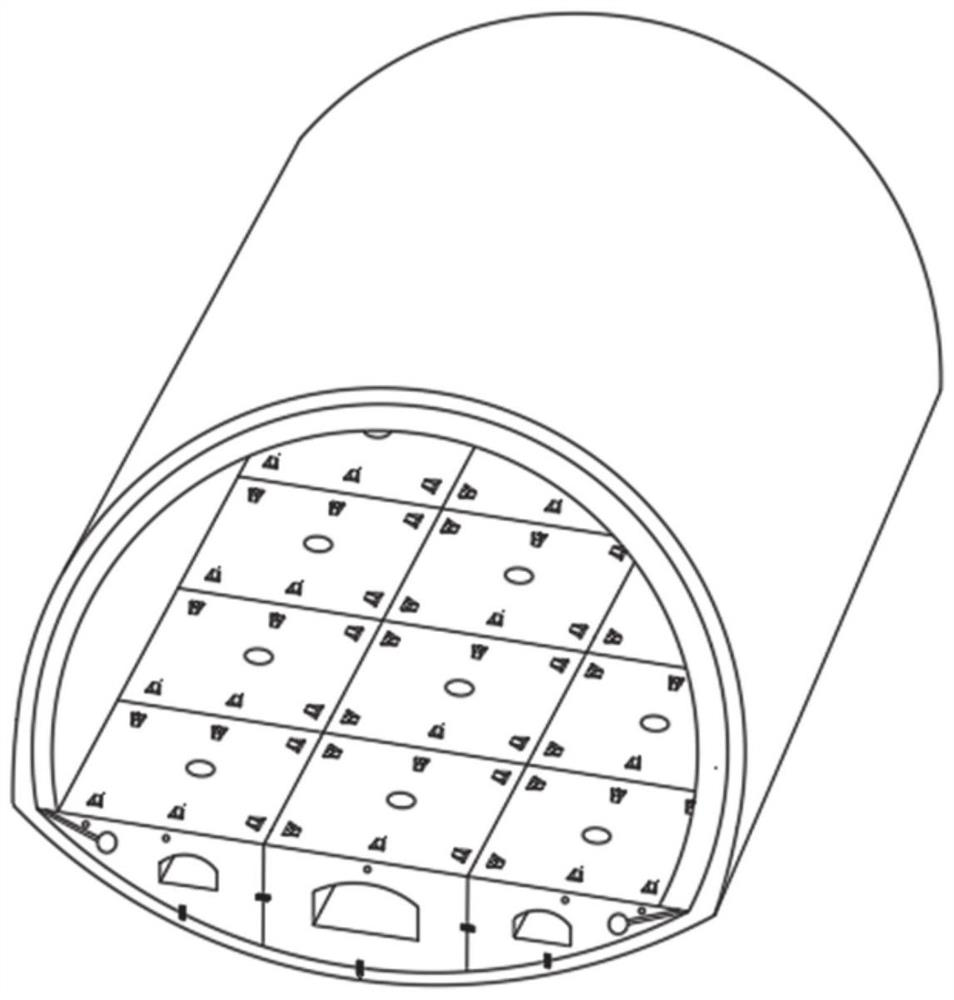

[0041] In a typical implementation of the present disclosure, such as Figure 1-Figure 7 As shown, a cavity fabricated tunnel invert is proposed.

[0042] The prefabricated tunnel invert mainly includes invert blocks arranged in sequence along the extension direction of the tunnel. The invert blocks are composed of multiple prefabricated blocks to form multiple rows of prefabricated blocks arranged in sequence along the tunnel extension direction;

[0043] The invert arch is prefabricated, and the components are made in the prefabricated yard. The quality and strength are reliable. It replaces the traditional invert arch trestle bridge cast-in-place method, reduces the manual and mechanical costs in the traditional invert construction, and accelerates the overall construction of the tunnel. .

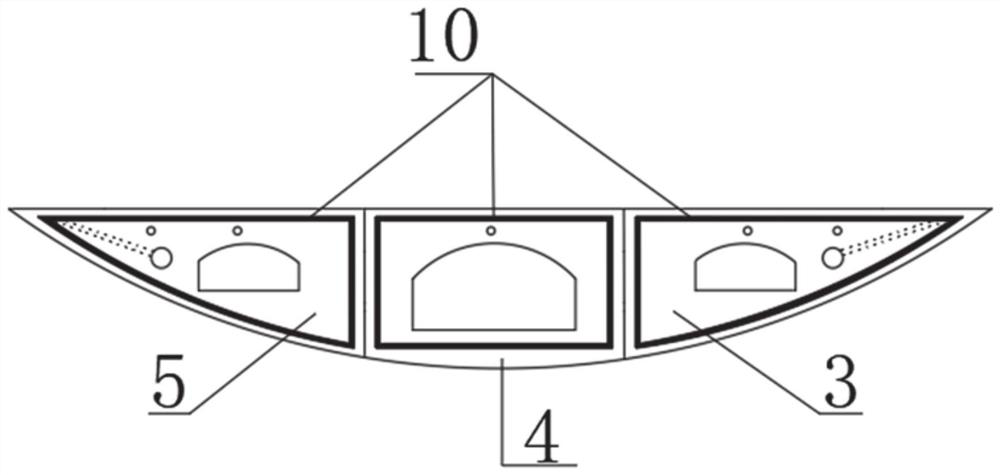

[0044] The invert block includes a first prefabricated block, a second prefabricated block, and a third prefabricated block arranged in sequence along the transverse direction of the tunnel. ...

Embodiment 2

[0072] In another exemplary embodiment of the present disclosure, such as Figure 1-Figure 7 As shown, a construction method of a cavity fabricated tunnel invert is proposed, using the cavity fabricated tunnel invert as described in Example 1.

[0073] It includes the following steps:

[0074] Pre-process the invert block, pre-process the tunnel, and arrange the invert cushion;

[0075] Lift each invert block in turn, and install the invert block in sequence along the longitudinal extension of the tunnel;

[0076] Align the passages in the invert blocks and connect the adjacent invert blocks in turn;

[0077] Construct a tunnel leveling layer on the top surface of the invert block, and arrange other auxiliary facilities.

[0078] Specifically, the construction process will be described in detail in combination with each structure in Example 1:

[0079] Pre-treatment of the first prefabricated block, the second prefabricated block and the third prefabricated block at the construction site...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com