Evaporation heat exchanger for recycling part surface dissipated heat and household miniature combined heat and power generation device

An evaporative heat exchanger and cogeneration technology, which is applied to the hot gas variable capacity engine device, evaporator/condenser, muffler device, etc., can solve the problem of the attenuation of the power generation capacity of the prime mover, the decrease of efficiency, and the increase of fan power consumption and noise. and investment costs, so as to avoid the decline of energy efficiency, increase the amount of recovered heat, and avoid the attenuation of power generation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

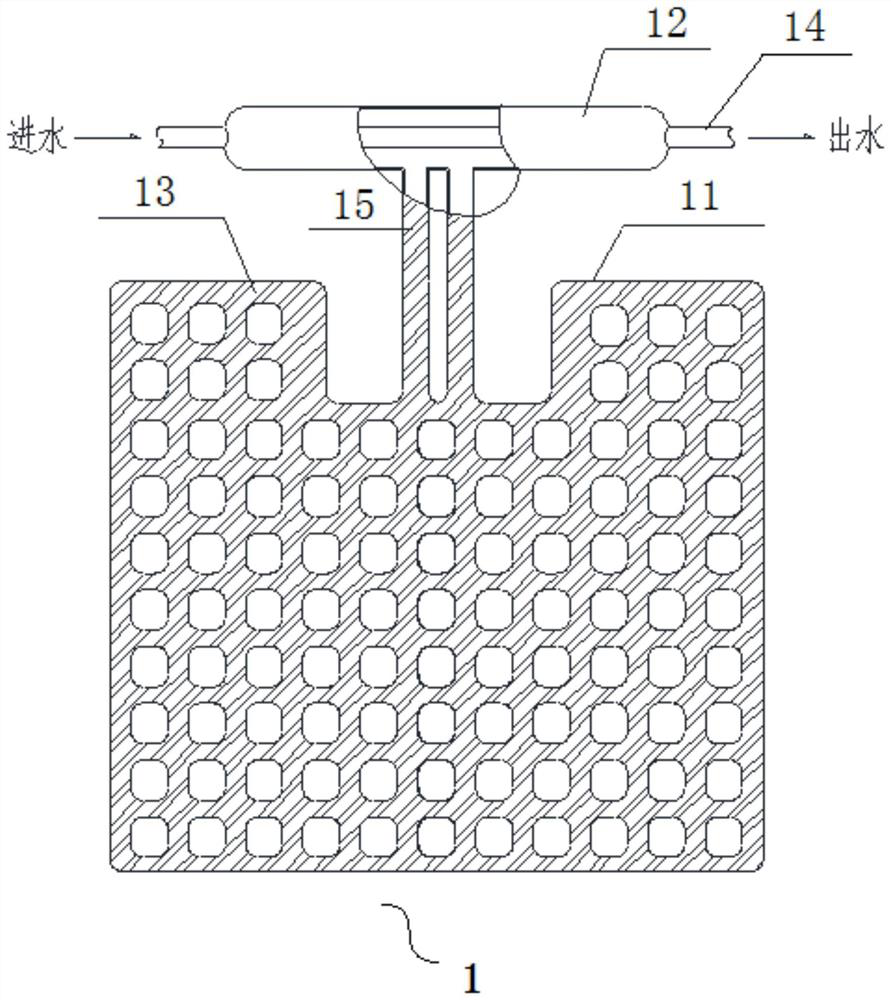

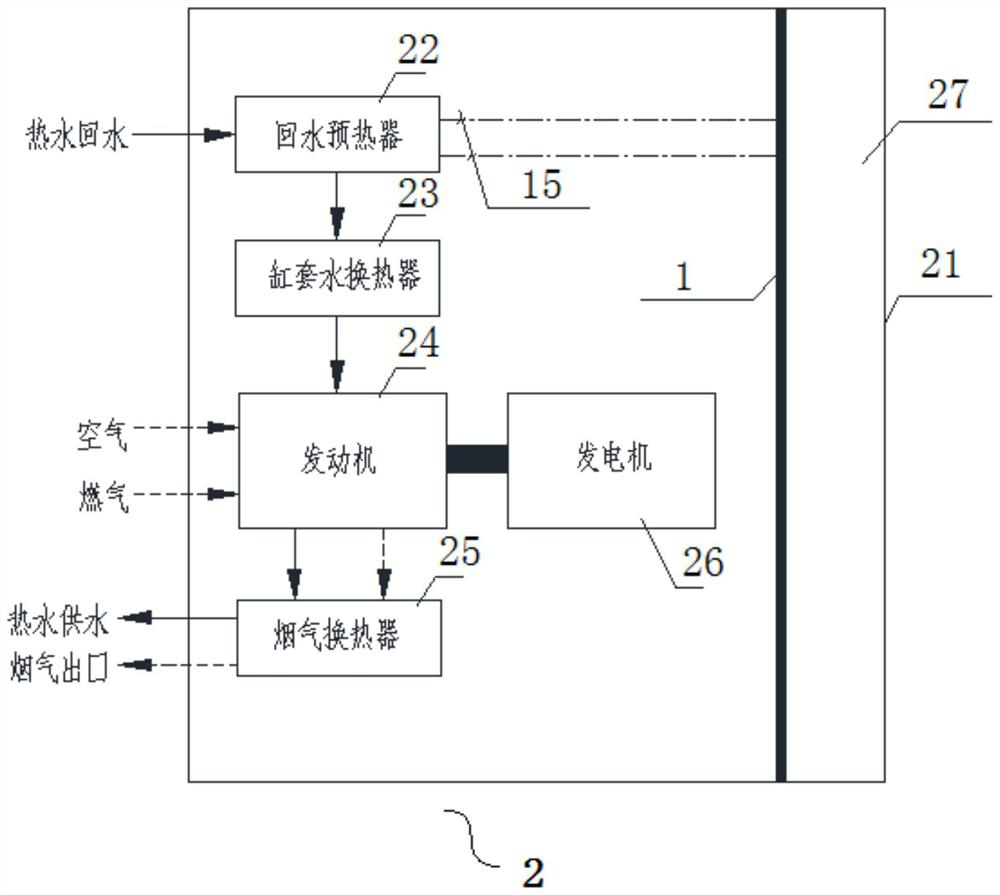

[0037] Such as figure 1 As shown, an evaporative heat exchanger 1 for recovering heat dissipation from the surface of components, the evaporative heat exchanger 1 is used to recover heat dissipation from the surface of components in the household micro cogeneration device 2, and the evaporative heat exchanger 1 is set in the household micro cogeneration device In the closed box 21 of the device 2, the evaporating heat exchanger 1 includes an evaporating section 11 and a condensing section 12, and the evaporating section 11 has a fluid passage 13 connected to each other, and the fluid passage 13 is filled with a working fluid for absorbing heat from the surface of the component, The condensing section 12 is arranged on the return water pipeline 14 of the household micro cogeneration device 2 , and the evaporating section 11 and the condensing section 12 are connected through a working fluid exchange pipeline 15 .

[0038] The condensing section 12 is set above the evaporating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com