Screw compressor complete machine

A technology of screw compressors and air compressors, applied in the direction of machines/engines, supporting machines, mechanical equipment, etc., can solve the problems of reducing the overall service life of air compressors, lack of buffer devices, and short cooling time, so as to improve cooling effect, reduction of overall requirements, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

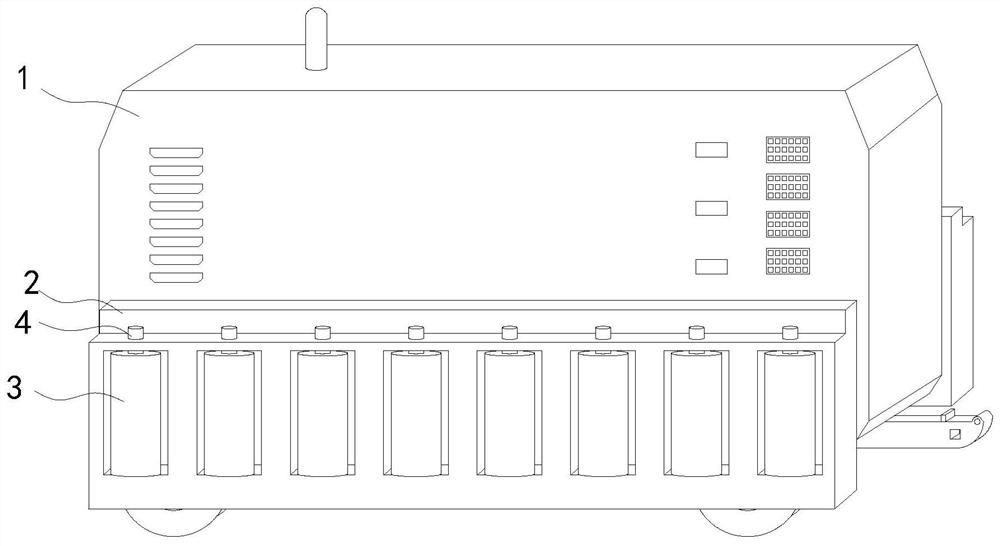

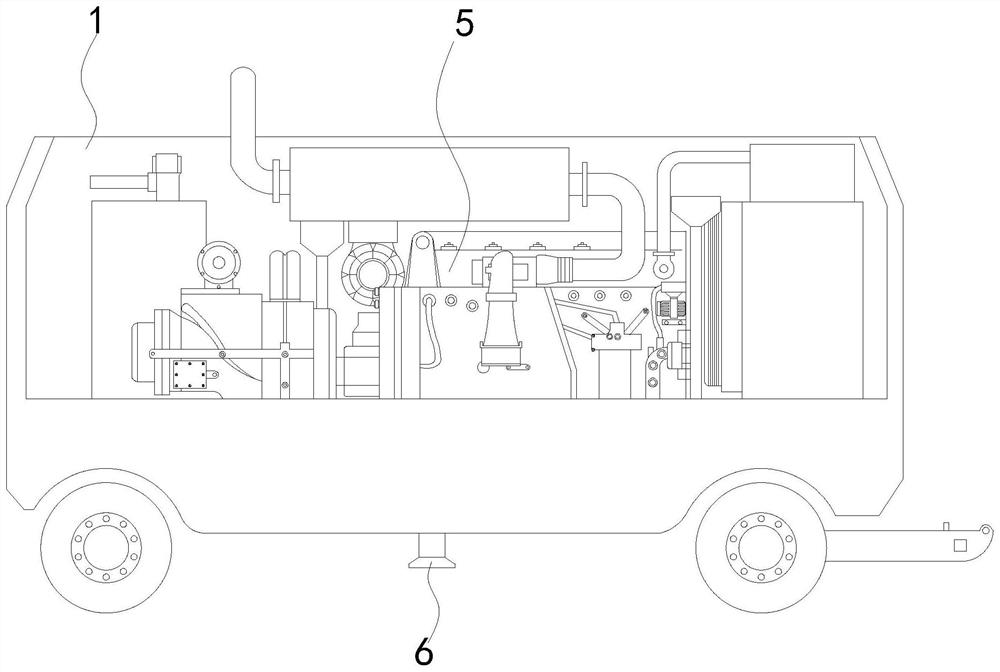

[0027] see Figures 1 to 8 , a schematic diagram of the planar structure and a schematic diagram of the three-dimensional structure of a screw compressor.

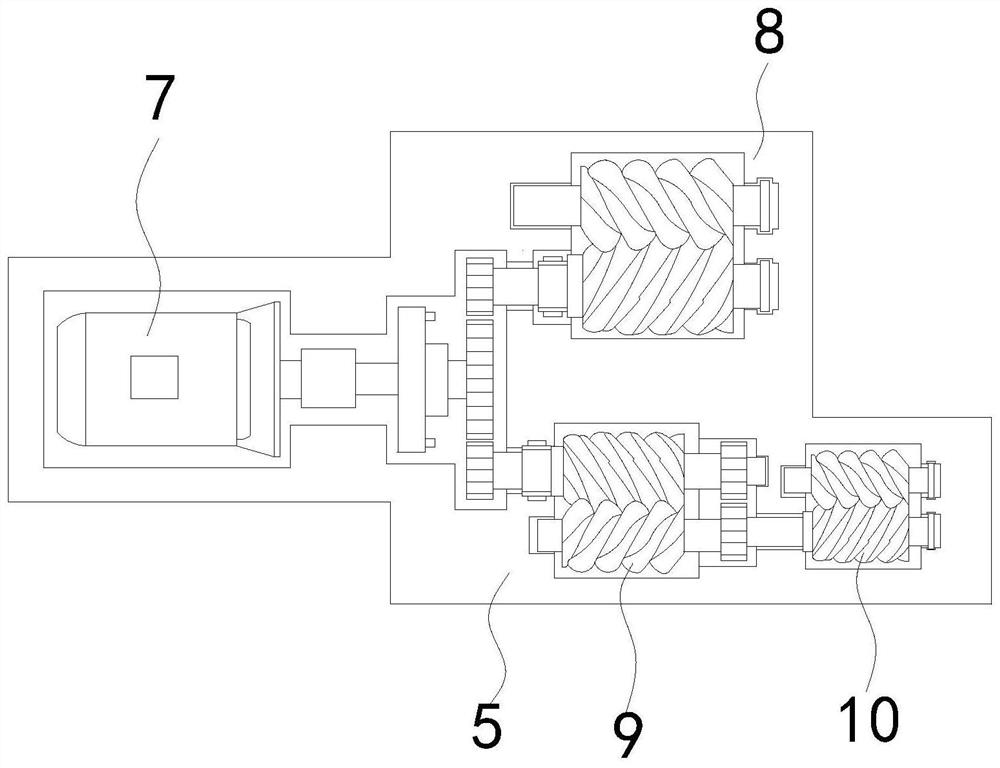

[0028] A screw compressor complete machine, including a mobile platform 1, an air compressor main body 5, a first-stage air compression device 8, a second-stage air compression device 9, a third-stage air compression device 10, and a mobile platform fixedly installed inside the air compressor main body 5 1. A buffer support device 2 is movably installed on the outer side. A support rod 6 is movably installed at the lower end of the mobile platform 1. A guide device 16 is fixedly installed at the lower end of the support rod 6.

[0029] In specific implementation, a drive motor 7 is fixedly installed on the left side of the air compressor main body 5, and the drive motor 7 is engaged with the gears on the left side of the primary air compression device 8 and the secondary air compression device 9. The side is engaged with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap