System for detecting molten salt leakage of photo-thermal power generation and heat storage device by utilizing electrode plates

A heat storage device and electrode sheet technology, applied in solar thermal power generation, solar heating systems, solar heat storage, etc., can solve the problems of molten salt leakage, difficulty in realizing all-round detection, limited number of thermocouples, etc., and achieve rapid positioning, Good high temperature and pressure resistance characteristics, the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with embodiments and drawings, but the present invention is not limited to this.

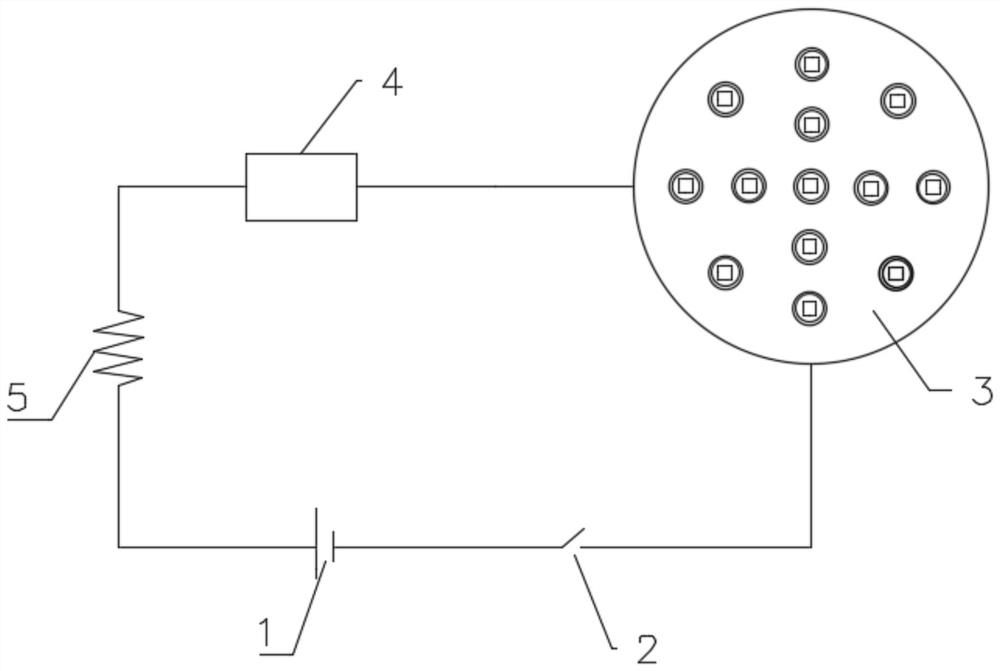

[0025] Such as figure 1 As shown, a system for detecting molten salt leakage in a thermal power storage device using electrode plates includes a DC stabilized power supply 1, a switch 2, an array electrode group 3, a data acquisition device 4, and a protection resistor connected in series in a detection circuit 5. The array electrode group 3 includes several single groups of electrode plates connected in parallel in the detection circuit, which belong to different detection branches. Any detection branch is turned on, so that the detection circuit can form a path, and the generated electrical signal can be collected by data The device 4 collects electrical signals including current, voltage, power, etc., and is used to determine whether molten salt leakage occurs.

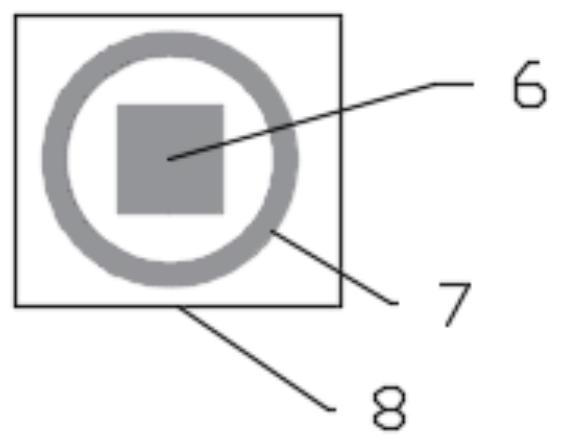

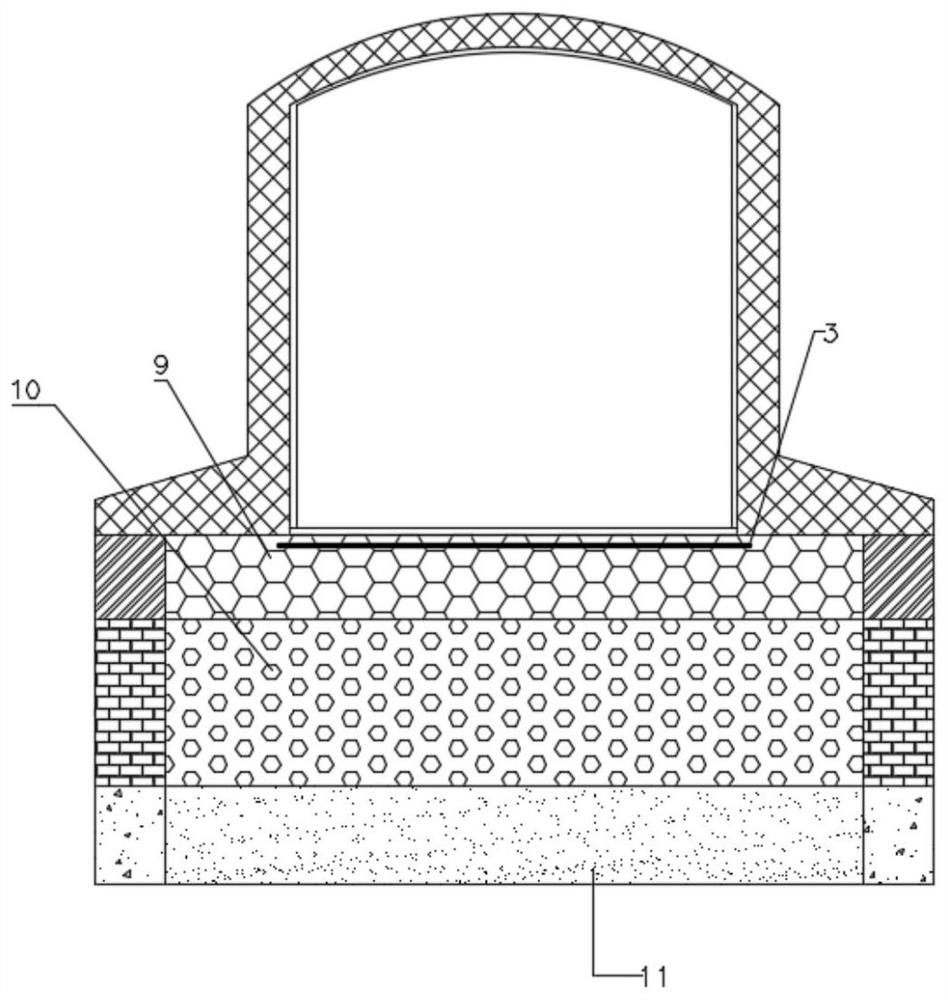

[0026] Such as figure 2 As shown in the structure diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com