A tool for detecting the thickness of fireproof coatings in fabricated steel structures

A fire-resistant coating and thickness detection technology, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems that the fire-resistant coating cannot meet the fire-resistant requirements, reduce the detection accuracy of the fire-resistant coating, and increase the labor intensity of the staff. Achieve the effects of avoiding random detection work, increasing practicability, and avoiding errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

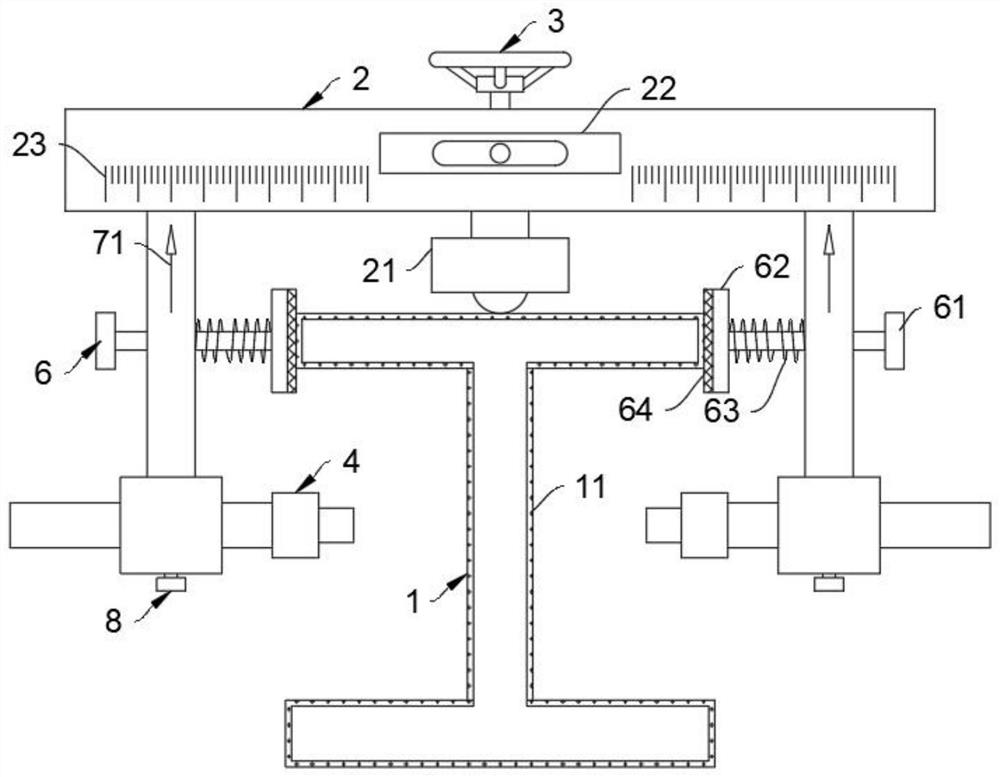

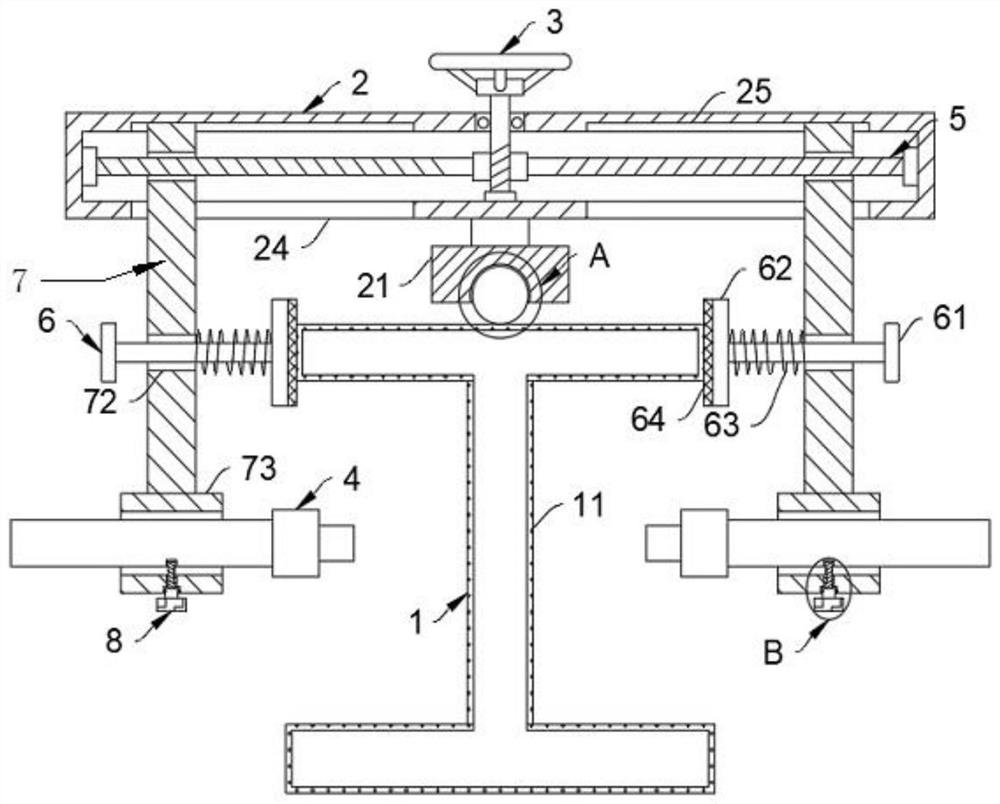

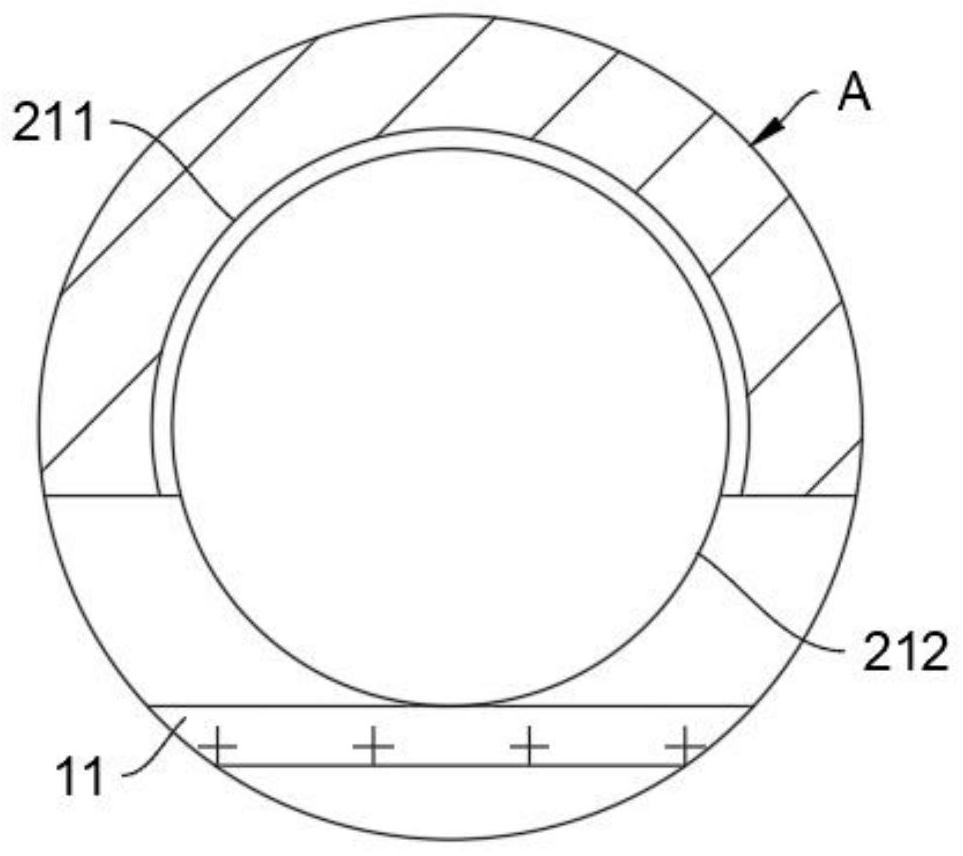

[0028] Such as Figure 1-5 As shown, a prefabricated steel structure building fireproof coating thickness detection tool includes a steel structure body 1. It should be noted that the steel structure body 1 adopts an I-shaped structure, and the surface of the steel structure body 1 is provided with a fireproof coating 11 for To ensure the fire safety of prefabricated steel structure buildings, the device conducts mobile inspection work through inspection tools to prevent the construction party from cutting corners and adulterating materials so that the fireproof coating of assembled steel components does not meet the specified fire resistance requirements.

[0029] The steel structure body 1 is movably connected with a moving seat 2. It should be noted that the moving seat 2 adopts a rectangular structure, and the moving seat 2 is fixedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com