Core wall deformation monitoring method for high rock-fill dam

A high rockfill dam and deformation monitoring technology, applied in the direction of measuring devices, navigation through speed/acceleration measurement, instruments, etc., can solve the problems of long manual measurement time, large errors, and easy breakage of the inclinometer tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] In order to deepen understanding of the present invention, the present invention will be described in further detail below in conjunction with examples, and present examples are only used to explain the present invention, and do not constitute the limitation to protection scope of the present invention.

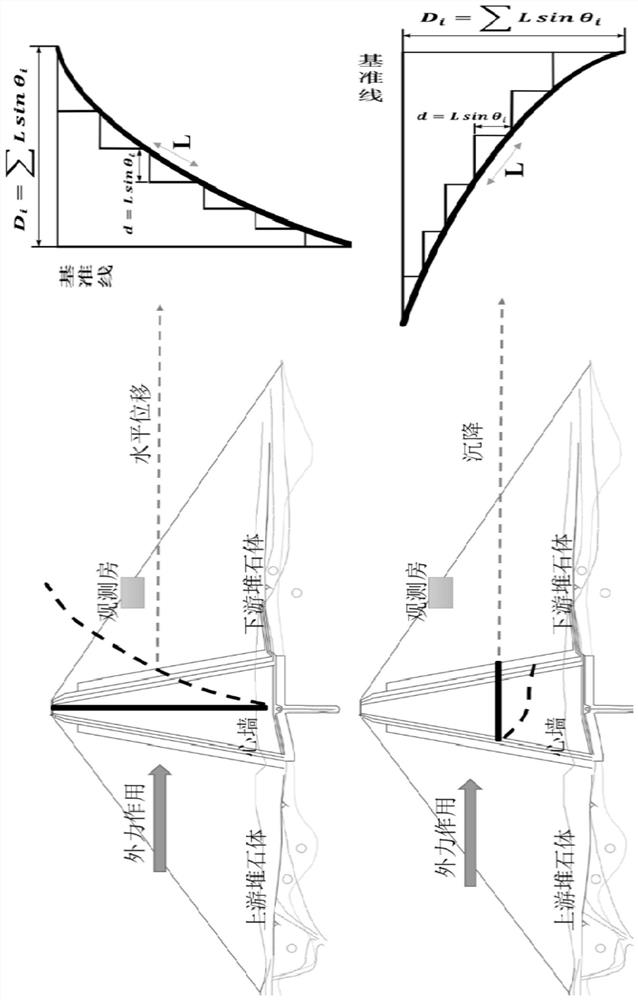

[0067] according to figure 1 , 2 , 3, 4, 5, and 6, the present embodiment provides a method for monitoring deformation of the core wall of a high rockfill dam, comprising the following steps:

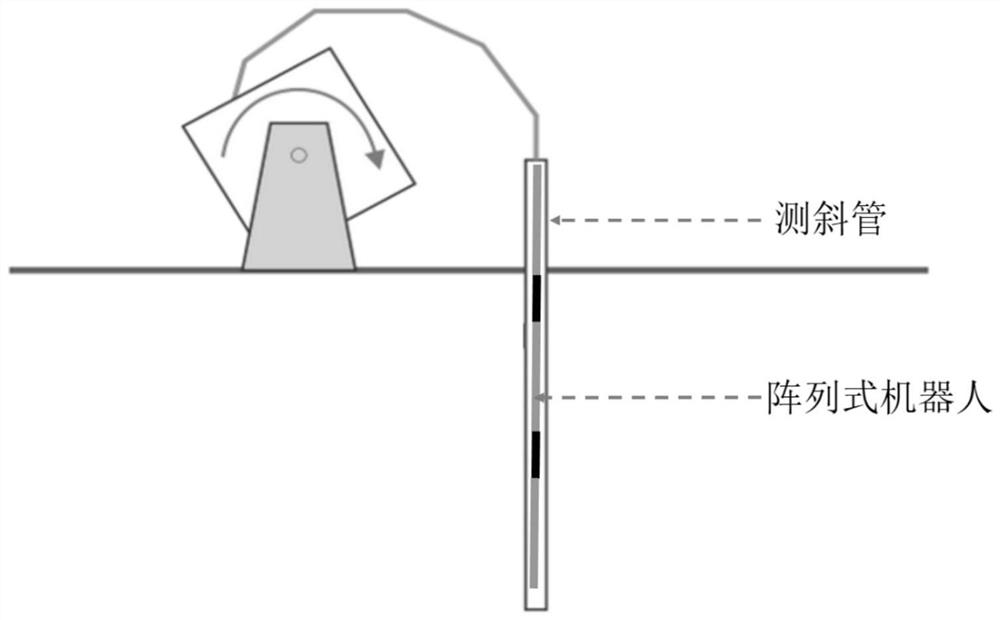

[0068] Step 1: Deploy the array robot

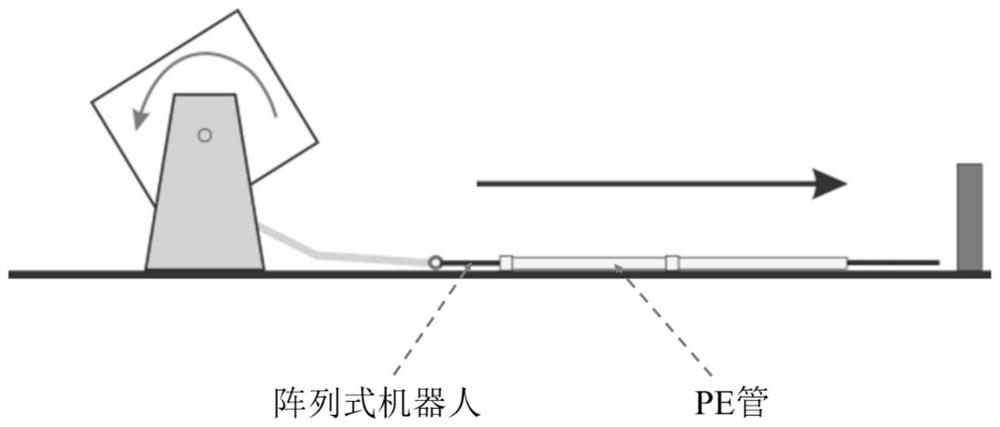

[0069] In the core wall of a large rockfill dam, the array robot measurement system is arranged horizontally and vertically, and MEMS inertial navigation is installed on each section of the array robot to record three-dimensional position information; figure 1 ;

[0070] Step 2: Set up the measurement carrier

[0071] Use PE pipes to protect the array robot. The array robot does not measure the three-dimensional curve of the pipe. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com