Transformer body wiring explosion-proof protection device

An explosion-proof protection, transformer technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor shell, transformer/inductor cooling, etc. and other problems to achieve the effect of ensuring safe use, enhancing fire resistance and flame retardant performance, and good high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

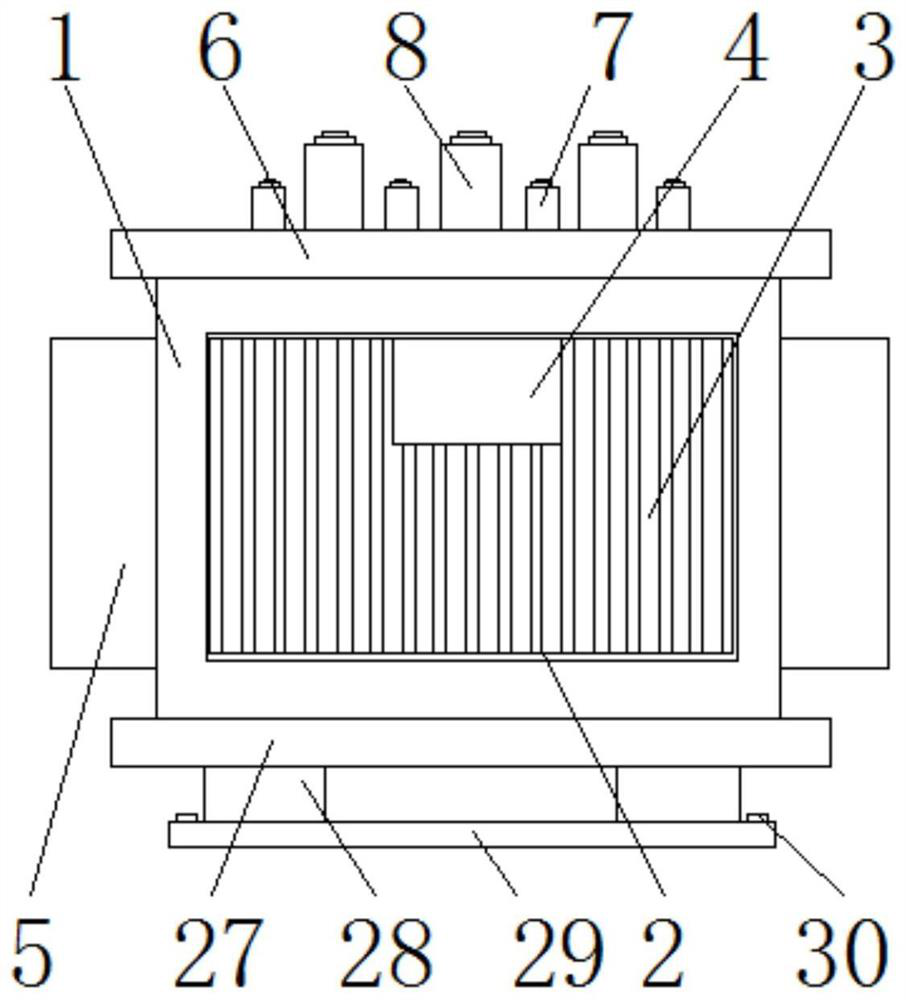

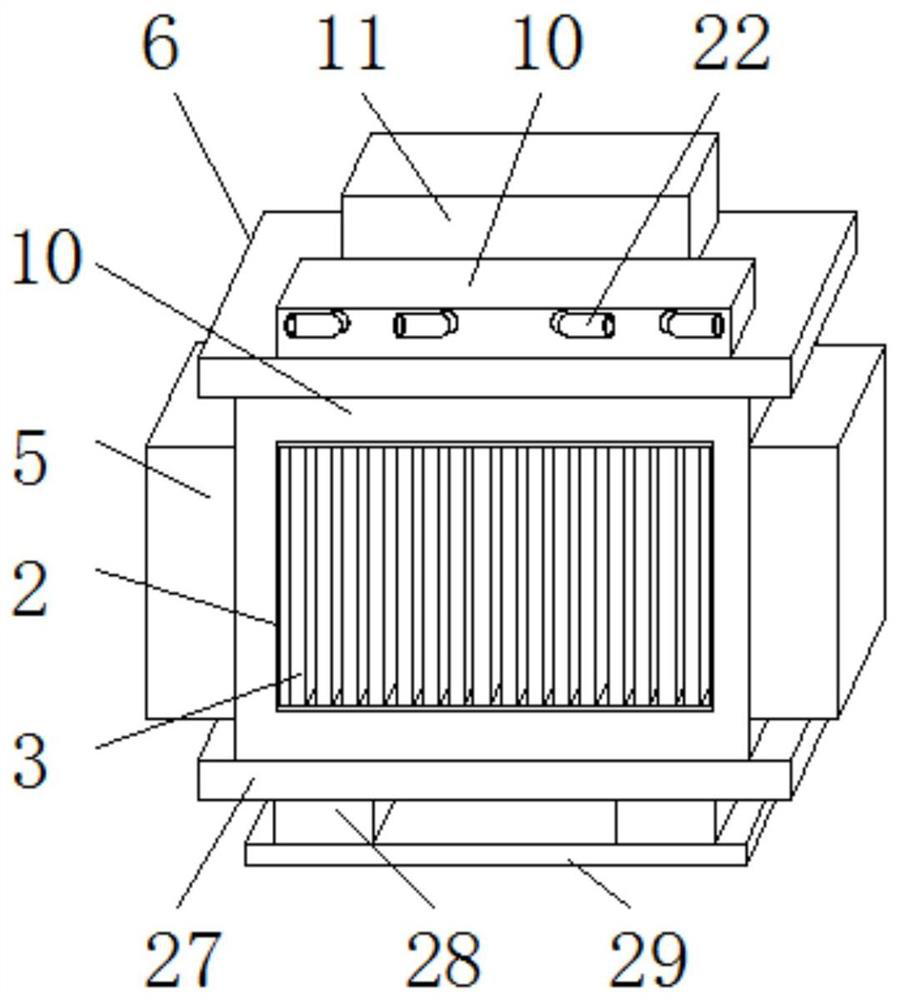

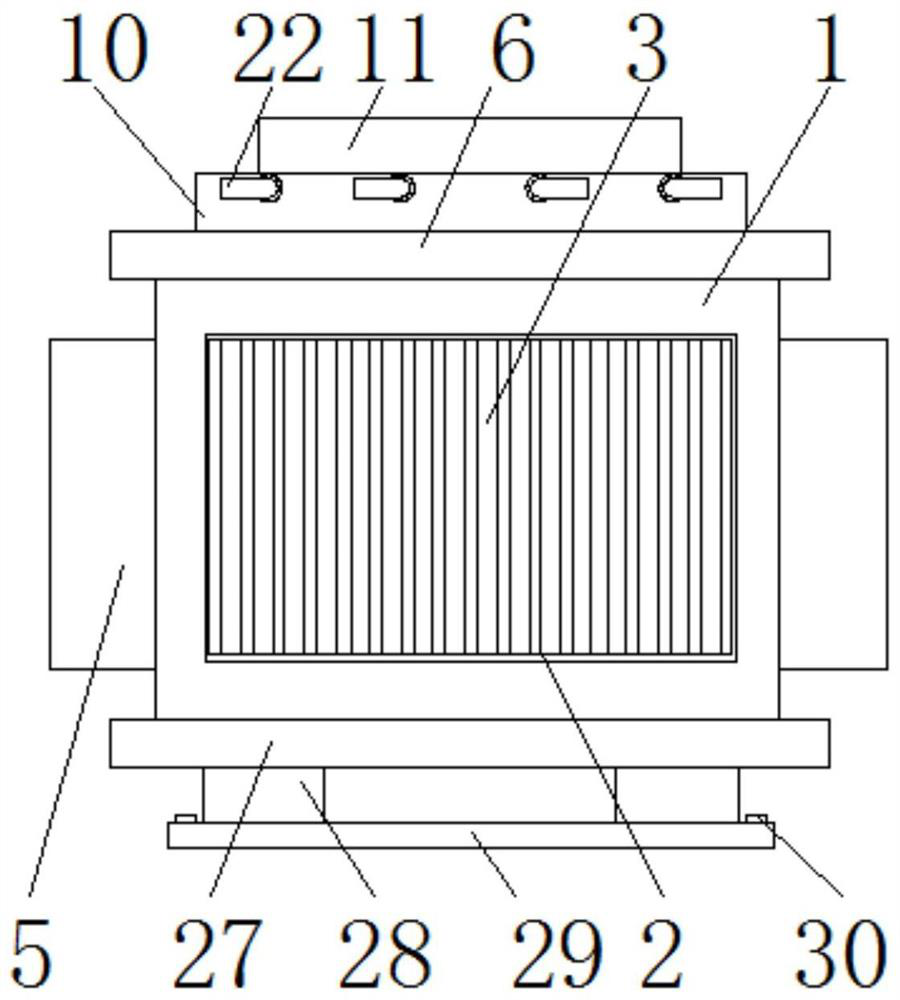

[0036] see Figure 1-7 , the present invention provides an explosion-proof protection device for transformer body wiring, which includes a housing 1, a groove 2 is opened in the middle of the front and rear surfaces of the housing 1, and several groups of cooling fins 3 are arranged inside the groove 2, which are located at the same Several groups of heat dissipation fins 3 on the side are distributed horizontally, and the positions of the heat dissipation fins 3 and the side of the outer surface close to each other of the housing 1 are vertically fixedly connected, and several groups of heat dissipation fins 3 are located on the top of the side of the outer surface of the housing 1 away from the same side. The nameplate 4 is fixedly installed between the middle positions, the outer walls of both sides of the housing 1 are welded with the box 5, and the top of the housing 1 is fixedly installed with the top plate 6, and the upper and lower surfaces of the top plate 6 are vertic...

Embodiment 2

[0038] see Figure 2-8 , the present invention provides an explosion-proof protection device for transformer body wiring, which includes a housing 1, a groove 2 is opened in the middle of the front and rear surfaces of the housing 1, and several groups of cooling fins 3 are arranged inside the groove 2, which are located at the same Several groups of heat dissipation fins 3 on the side are distributed horizontally, and the positions of the heat dissipation fins 3 and the side of the outer surface close to each other of the housing 1 are vertically fixedly connected, and several groups of heat dissipation fins 3 are located on the top of the side of the outer surface of the housing 1 away from the same side. The nameplate 4 is fixedly installed between the middle positions, the outer walls of both sides of the housing 1 are welded with the box 5, and the top of the housing 1 is fixedly installed with the top plate 6, and the upper and lower surfaces of the top plate 6 are vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com