Small methanol reforming hydrogen production device system based on tail gas waste heat utilization

A reforming hydrogen production device and waste heat technology, which can be used in hydrogen, electrical components, fuel cell heat exchange, etc., and can solve the problems of difficult storage and difficult hydrogen transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

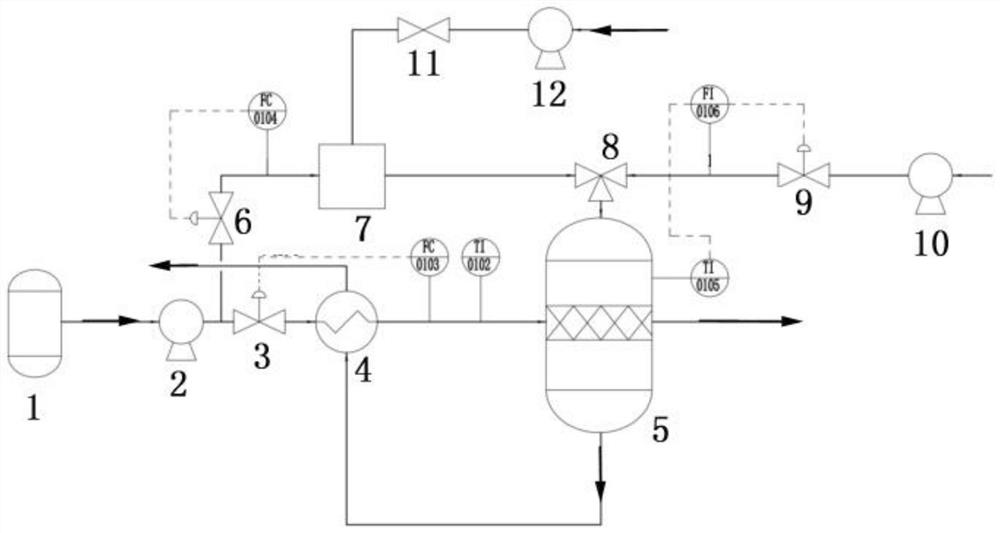

[0017] Example: Control figure 1

[0018] A small-scale methanol reforming hydrogen production plant system based on the utilization of tail gas waste heat, including a raw material storage tank 1 filled with methanol aqueous solution, a raw material pump 2, a first regulating valve 3, a preheater 4, and a reforming catalyst bed filled inside The reformer 5, the third regulating valve 9 and the tail gas blower 10 of the first layer, the reformer 5 is provided with a thermometer for detecting the temperature of the reforming catalyst bed inside it, and the outer side of the reformer 5 is provided with a heat exchange interlayer, the The preheater 4 adopts a heat exchanger structure; the tail gas fan 10 is connected with the heat exchange interlayer inlet of the reformer 5 through the third regulating valve 9 by pipelines, and the heat exchange interlayer outlet of the reformer 5 is connected with the heat exchange interlayer of the preheater 4. The channels are connected by pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com