Preparation method of granular seasoning salt

A technology of seasoning salt and granules, applied in the field of salt processing, can solve the problems of poor product uniformity, influence of seasoning, late research and development time, etc., and achieve the effect of overcoming strong adhesion, improving shelf life, and avoiding the adhesion of salt particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

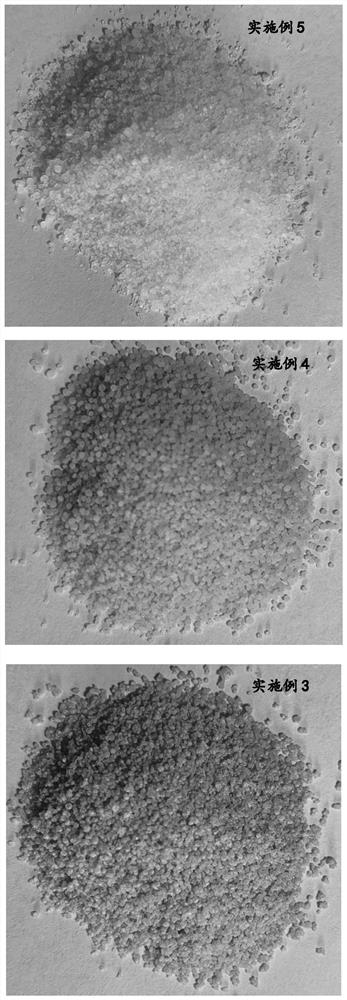

Image

Examples

Embodiment 1

[0037] A preparation method of granular seasoning salt, which comprises the steps of:

[0038] 1) Preparation of coating solution

[0039] Mix the yeast extract, gum arabic, and seasoning water extract to obtain a primary coating solution for use; add the gum arabic to water for dissolving and mixing to obtain a second coating solution for use;

[0040] 2) One time coating

[0041] Put the raw material salt into the fluidized bed cavity for preheating to make it in a good fluidized state, then pass the primary coating solution obtained in step (1) into the fluidized bed cavity, and atomize the primary coating solution Coating raw material salt once;

[0042] 3) Secondary coating

[0043] After the primary coating is completed and the outlet temperature is stable, the secondary coating solution obtained in step (1) is passed into the fluidized bed cavity, and the secondary coating solution is atomized to perform secondary coating on the raw material salt;

[0044] 4) Mixing...

Embodiment 2

[0048] A preparation method of granular seasoning salt, which comprises the steps of:

[0049] 1) Preparation of coating solution

[0050] Mix the yeast extract, gum arabic, and seasoning water extract to obtain a primary coating solution for use; add the gum arabic to water for dissolving and mixing to obtain a second coating solution for use;

[0051] 2) One time coating

[0052] Put the raw material salt into the fluidized bed cavity for preheating to make it in a good fluidized state, then pass the primary coating solution obtained in step (1) into the fluidized bed cavity, and atomize the primary coating solution Coating raw material salt once;

[0053] 3) Secondary coating

[0054] After the primary coating is completed (i.e., the primary coating solution is sprayed) and the outlet air temperature is stable, continue to maintain the raw material salt in a good fluidized state, and control the temperature of the raw material salt to 45-65°C for drying for 10 ~15min, aft...

Embodiment 3

[0060] A preparation method of granular seasoning salt, which comprises the steps of:

[0061] 1) Preparation of coating solution

[0062] Mix 7.5kg of yeast extract, 1kg of gum arabic, and 14kg of seasoning water extract to obtain 22.5kg of a primary coating solution for use; add 1kg of gum arabic to 2kg of water for dissolving and mixing to obtain 3kg of a secondary coating solution , and set aside; wherein, the seasoning water extract is prepared by the following method: adding mushroom powder to water (the mass ratio of mushroom powder to water is 1:200), soaking for 30-60min, passing through an 80-mesh filter, and taking The filtrate is the seasoning water extract, which is set aside.

[0063] 2) One time coating

[0064] Put 88.5 kg of raw material salt into the cavity of the fluidized bed for preheating to make it in a good fluidized state, and then pass all the primary coating liquid obtained in step (1) into the cavity of the fluidized bed to coat the primary coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com