Indicating light assembly installation structure of carbon dioxide laser machine

A technology of component installation and carbon dioxide, which is applied in the field of medical laser machines, can solve the problems of occupying the height space of the chassis, inconvenient installation and maintenance, and the size and space occupied by the indicator light components, so as to achieve the effect of convenient installation, convenient installation and maintenance, and lower design height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

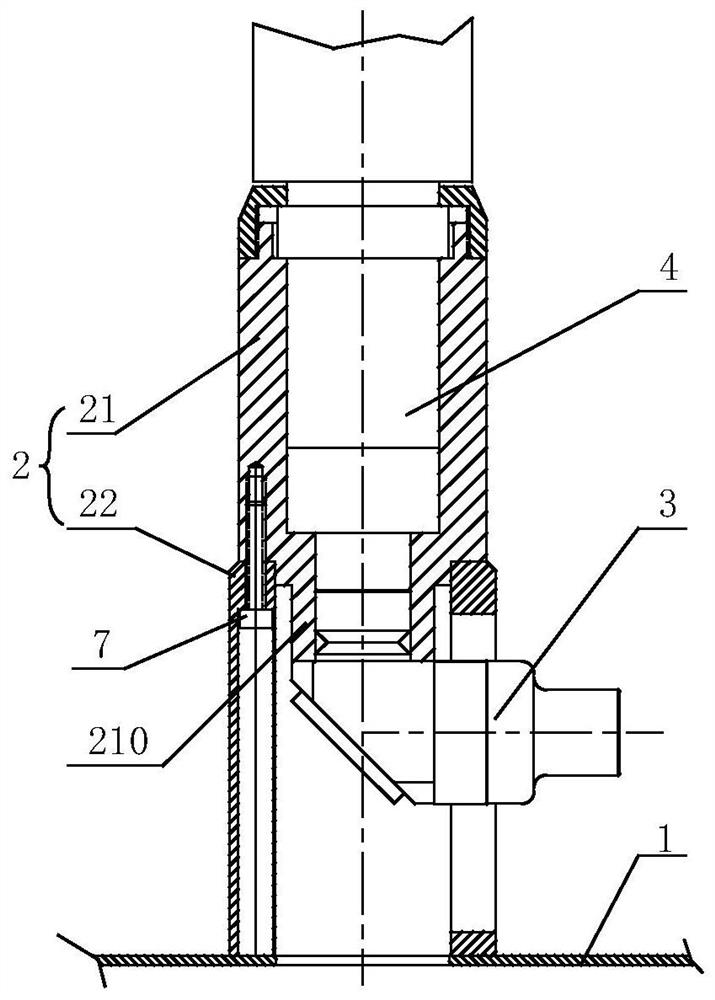

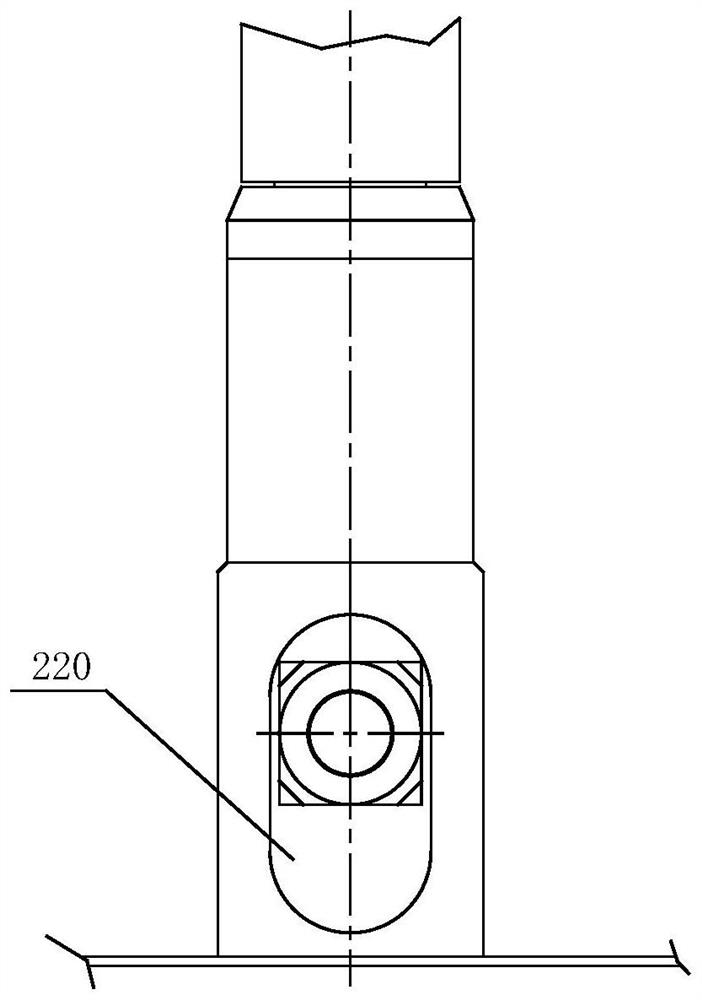

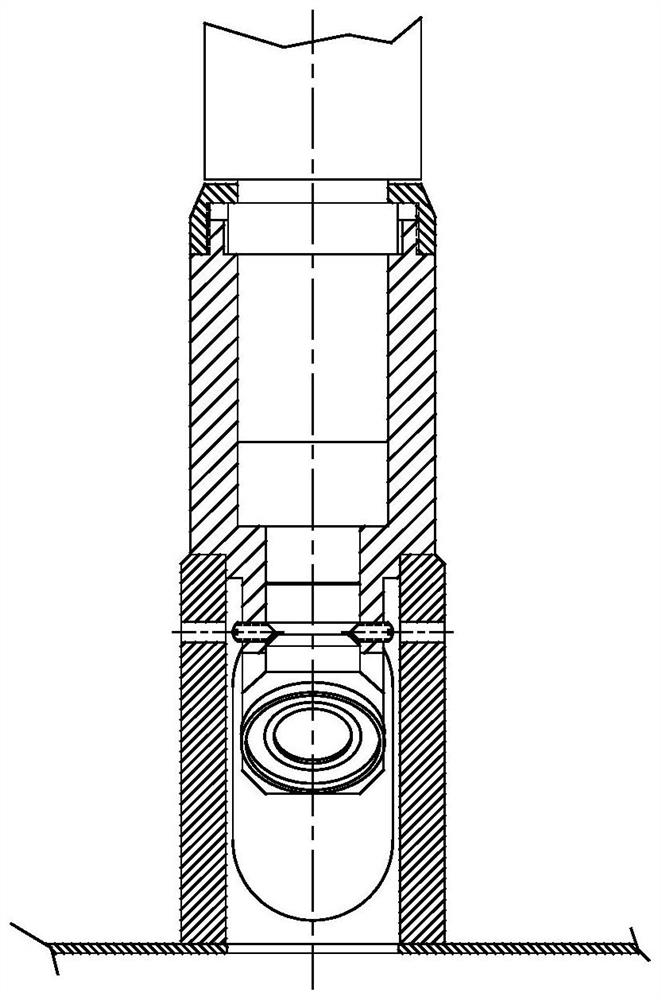

[0029] to combine Figure 1 to Figure 4 As shown, a carbon dioxide laser machine indicator light component installation structure, including the chassis 1, the light guide arm base assembly 2 installed on the top of the chassis 1 and the indicator light component 3, the indicator light component 3 is installed on the light guide arm base Middle section of component 2.

[0030] continue to refer figure 1 with figure 2 , the light guide arm base assembly 2 is cylindrical, and it includes the upper section 21 of the light guide arm base and the lower section 22 of the light gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com