Dust removal and purification equipment and dust removal and purification process

A technology of purification equipment and dust, which is applied in the field of air purification, can solve the problems of inability to remove dust and low dust removal efficiency, and achieve the effect of dust-free operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

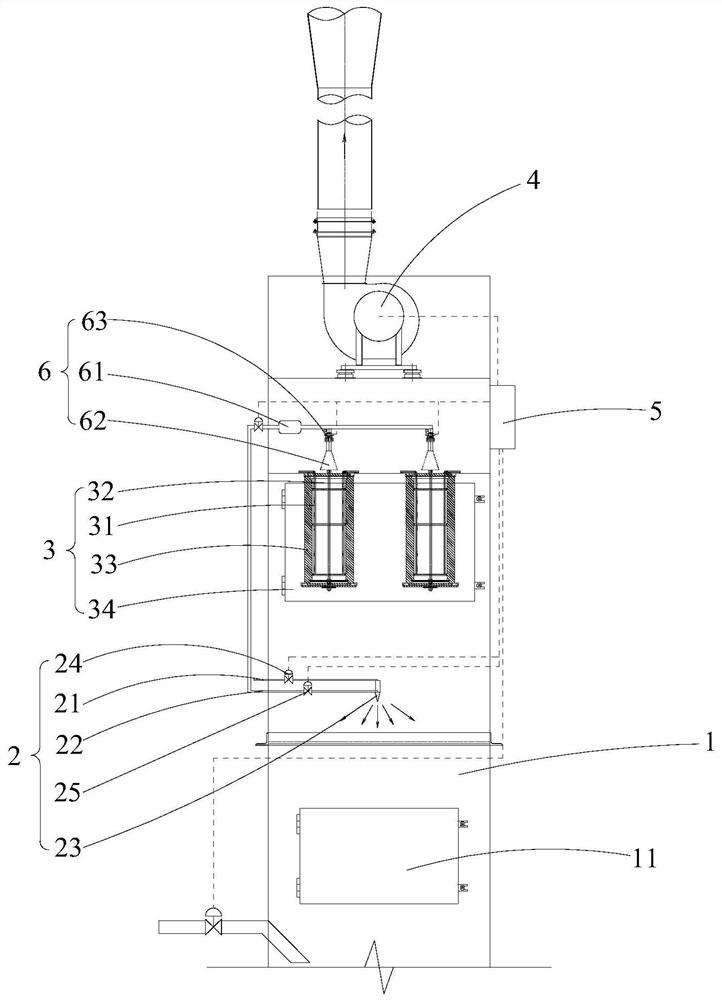

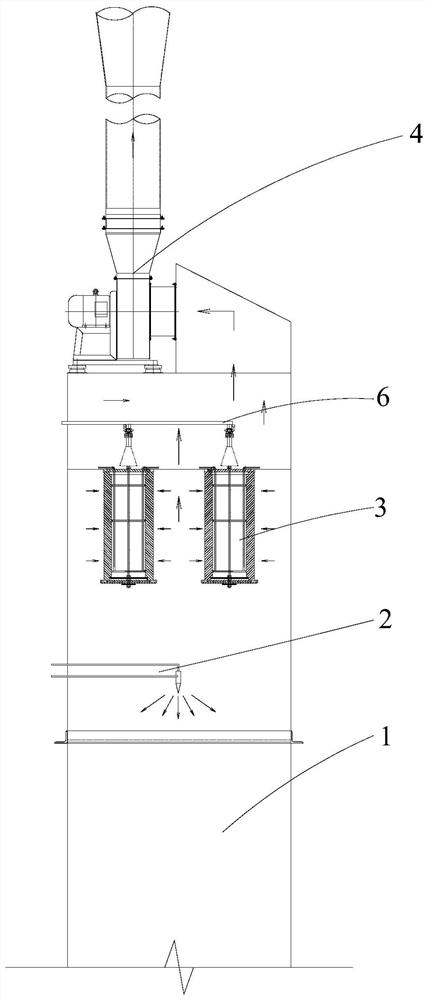

[0038] Further, see figure 1As shown, as a specific embodiment of the dust removal and purification equipment provided by the present invention, the atomizer assembly 2 includes a water pipe 21 and an air pipe 22, the water pipe 21 can be used for external water flow into the barrel 1, and the air pipe 22 It can be used to guide external air into the barrel 1. The water pipe 21 and the air pipe 22 are both arranged on the barrel 1 at intervals. In addition, the atomizer assembly 2 also includes an atomizer 23, and the atomizer 23 is arranged on the In the barrel 1, the atomizer 23 communicates with the water pipe 21 and the air pipe 22, and atomizes the air and water flow. In this way, when the air and water flows into the atomizer 23 respectively, the nozzle of the atomizer 23 can precisely control the mixing ratio of air and water to realize the mixed atomization of gas and liquid, and the friction between the compressed air and the liquid produces relatively Uniform and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com