Bucket elevator for concrete batching

A bucket elevator, concrete technology, applied in the direction of conveyors, sales of raw material supply devices, transportation and packaging, etc., can solve the problem of reducing the efficiency of stone materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

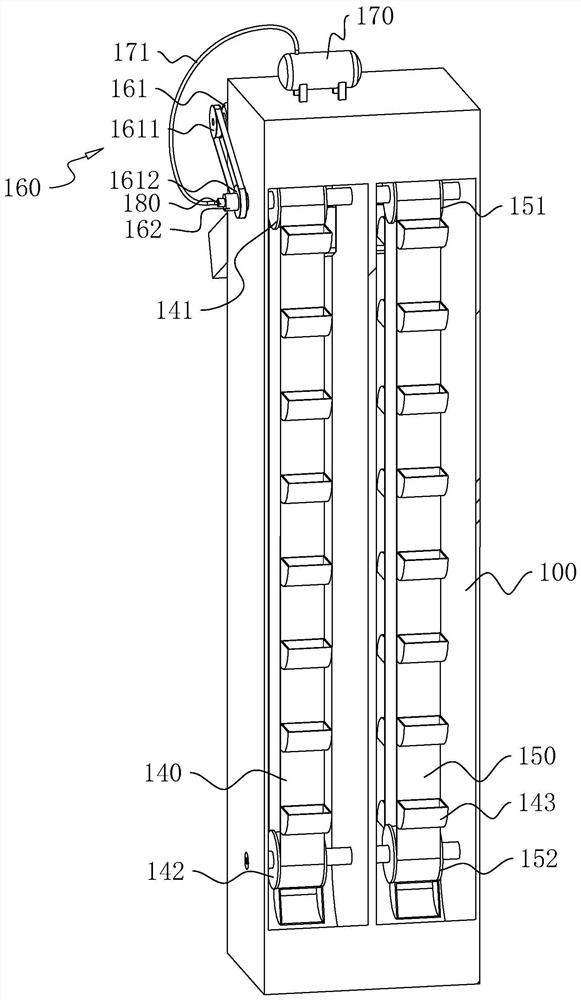

[0036] The following is attached Figure 1-6 The application is described in further detail.

[0037] The embodiment of the present application discloses a bucket elevator for concrete batching.

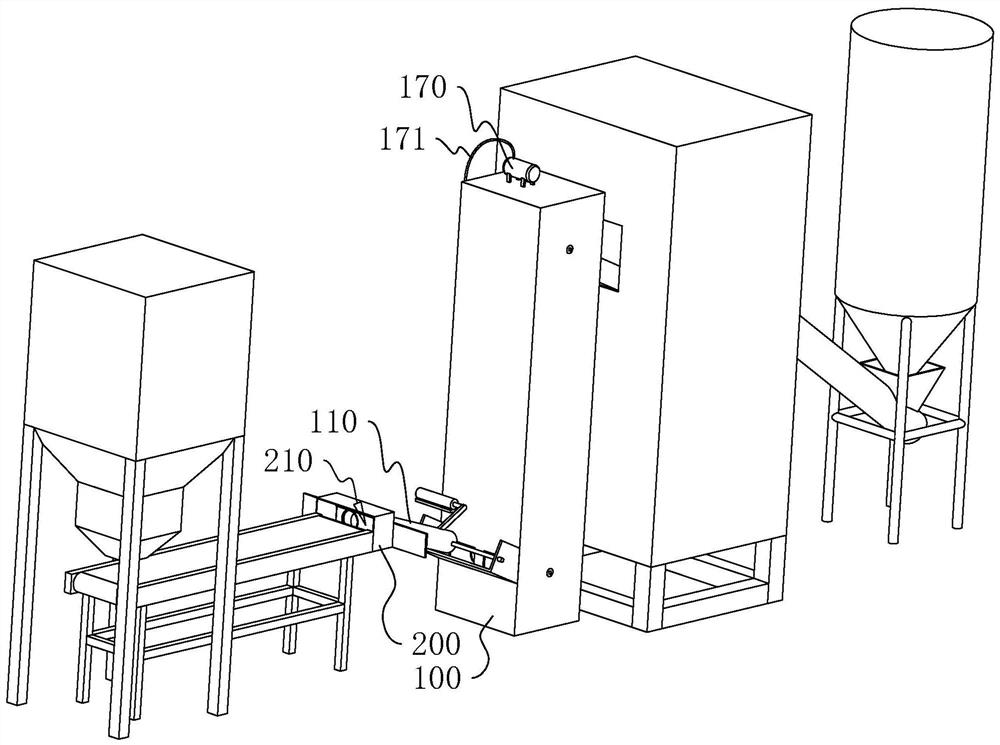

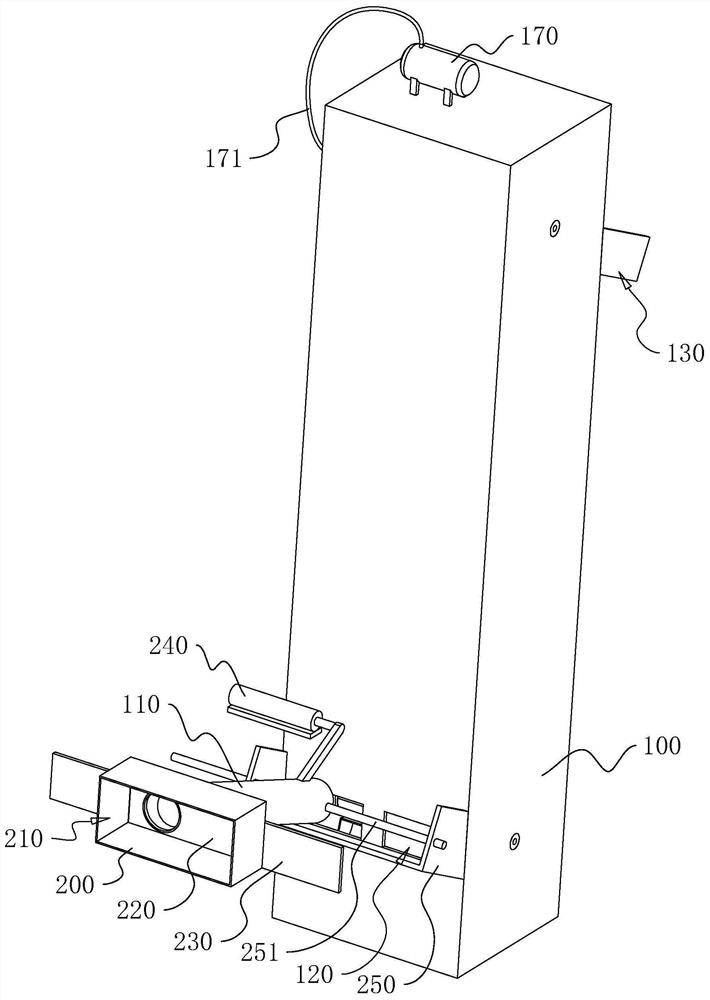

[0038] refer to figure 1 and figure 2 The bucket elevator for concrete batching includes a housing 100 and an inclined feed pipe 110, and an auxiliary seat 200 is fixed on the frame at the outlet of the belt conveyor. discharge hole 210 . The feed pipe 110 is horizontally slidingly connected to the auxiliary seat 200 , and sliding plates 220 are fixed on both sides of the feed pipe 110 axis. Both ends of the auxiliary base 200 are fixed with a fixing plate 230 , and the two sliding plates 220 are respectively slid inside the fixing plate 230 . The diameter of the feeding pipe 110 is equal to the height of the outlet hole 210 . A feed port 120 is provided at the lower end of the housing 100, and the end of the feed pipe 110 away from the auxiliary seat 200 slides horizontally on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com