Easy-to-tear film for plastic container and preparation method

A technology for plastic containers and films, used in chemical instruments and methods, flat products, flexible coverings, etc., to improve the effect of heat sealing, improve sealing quality, and facilitate management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

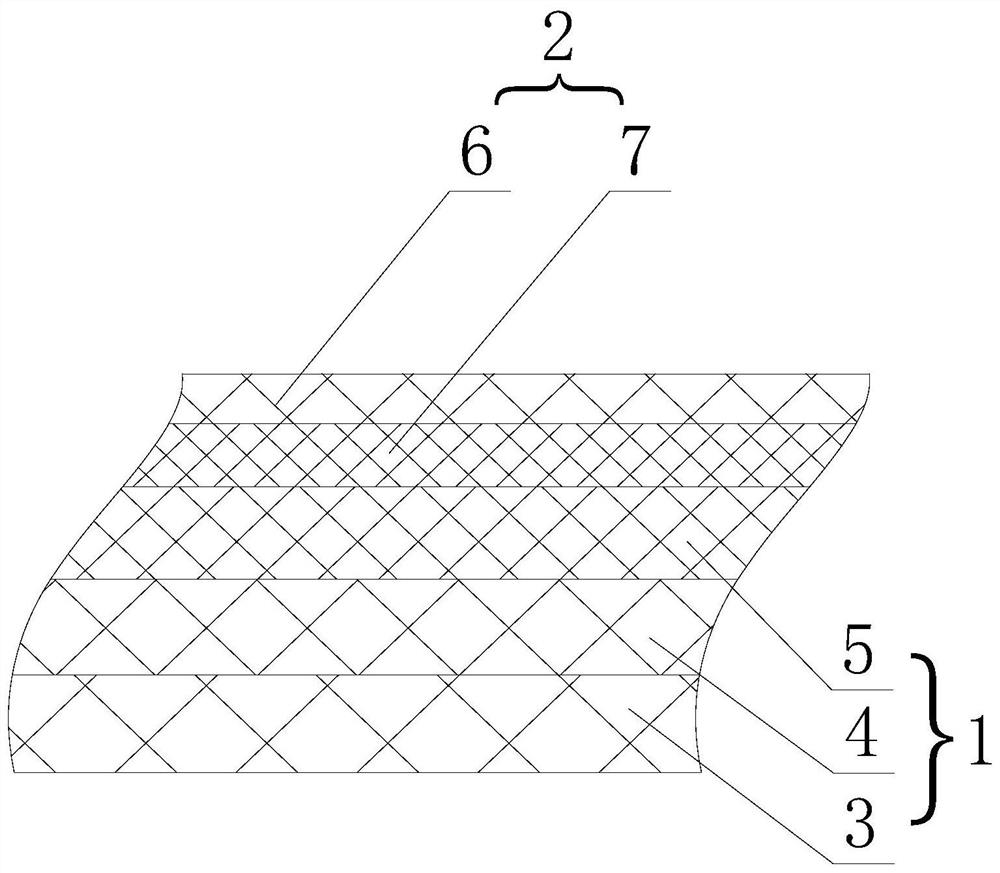

[0025] like figure 1 As shown, an easy-to-tear film for a plastic container includes a film body, the film body includes an inner film 1 and an outer film 2 compounded on the inner film 1, and the inner film 1 includes the following components: 60 to 70 weight 10-20 parts by weight of polypropylene, 10-20 parts by weight of ethylene-vinyl acetate copolymer, 10-20 parts by weight of ethylene-acrylic acid copolymer and 5-10 parts by weight of ionic polymer.

[0026] The inner membrane formed by polypropylene, ethylene-vinyl acetate copolymer, ethylene-acrylic acid copolymer and ionomer, due to the heating of polypropylene, ethylene-vinyl acetate copolymer, ethylene-acrylic acid copolymer and ionomer After melting, the inner membrane is not only physically bonded to the plastic container, but also has the ability to produce chemical bonds on the surface of the inner membrane. Since vinyl acetate and acrylic acid have acid radical bonds, both acid radical bonds and ionic bonds are...

Embodiment 2

[0030] An easy-to-tear film for a plastic container, comprising a film body, the film body including an inner film and an outer film on the composite inner film, the inner film comprising the following components: 62 parts by weight of polypropylene, 15 parts by weight of Ethylene-vinyl acetate copolymer, 17 parts by weight of ethylene-acrylic acid copolymer and 6 parts by weight of ionomer.

Embodiment 3

[0032] An easy-to-tear film for a plastic container, comprising a film body, the film body including an inner film and an outer film compounded on the inner film, the inner film comprising the following components: 62 parts by weight of polypropylene, 14 parts by weight of Ethylene-vinyl acetate copolymer, 16 parts by weight of ethylene-acrylic acid copolymer and 8 parts by weight of ionomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com