A fully automatic milk tea machine

A milk tea machine, fully automatic technology, applied in packaging machines, conveyor objects, packaging and other directions, can solve the problem of low milk tea efficiency, achieve the effect of simple structure, low manufacturing cost, and ensure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

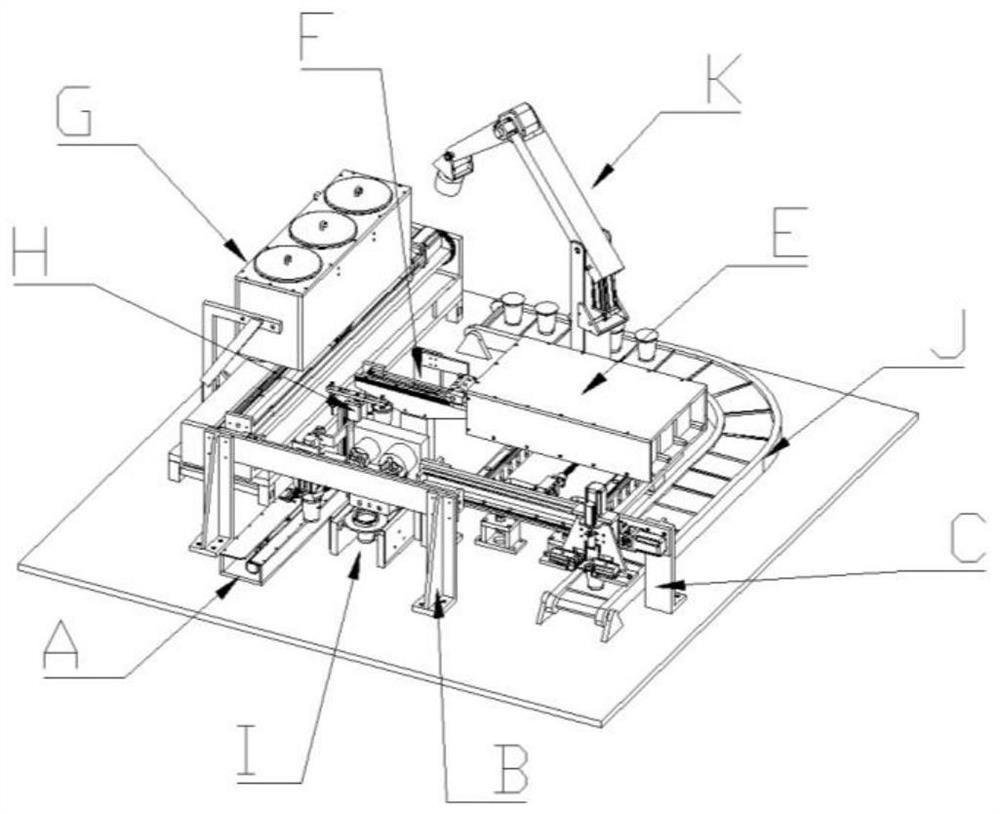

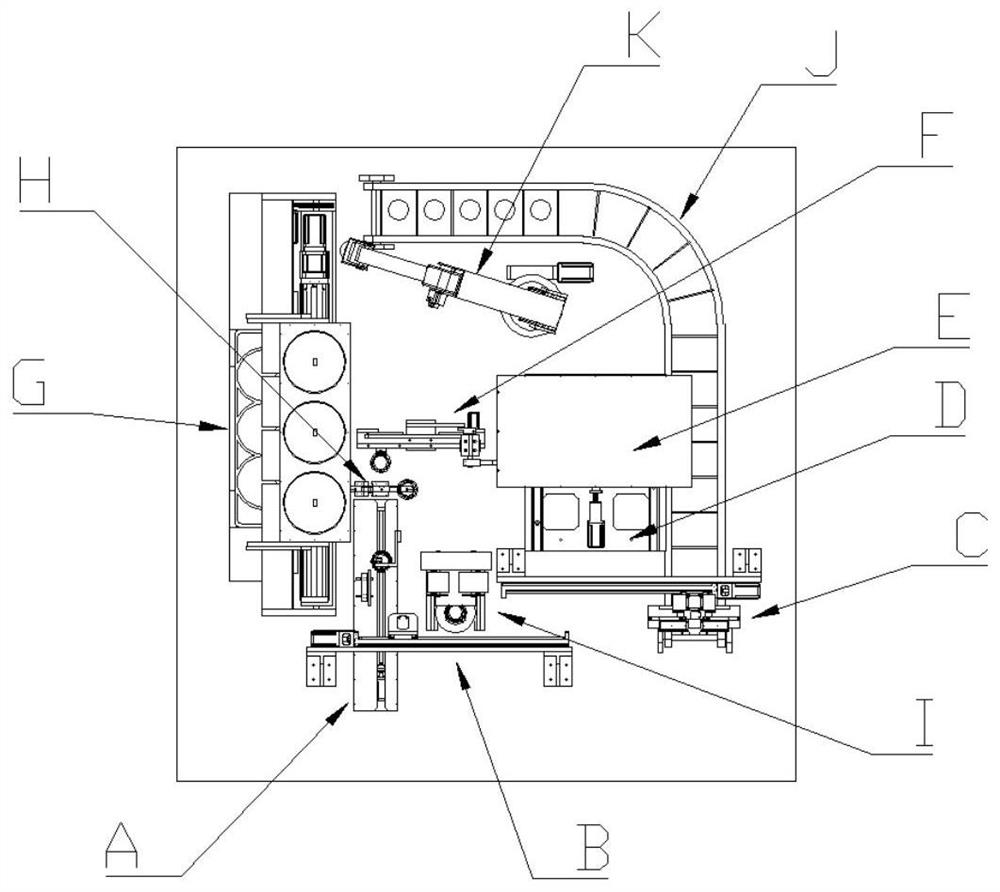

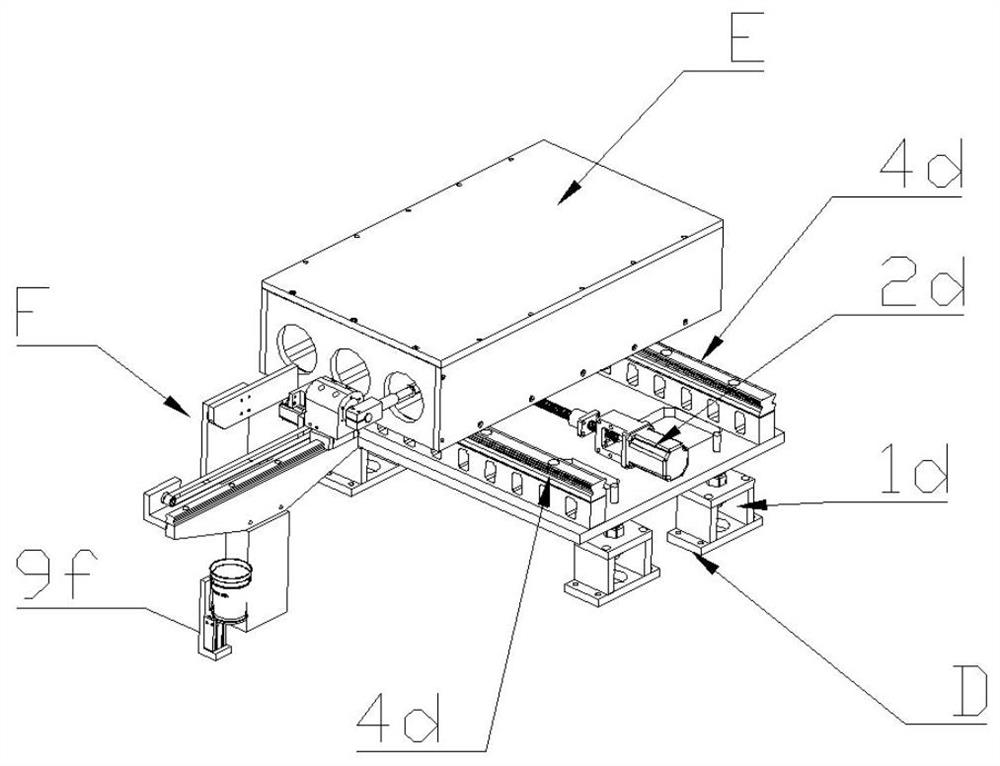

[0061] see Figure 1-Figure 53 , the fully automatic milk tea machine of the present invention includes a reclaiming system G, a shaking system K, a pouring system, a capping system I, a cup taking system and a conveying system, wherein,

[0062] The reclaiming system G is used to automatically feed the raw materials corresponding to making the milk tea into the receiving container 8g according to the different types of milk tea to be made;

[0063] The cup taking system is used to take out the milk tea cups one by one;

[0064] The conveying system includes a first conveying device A for conveying the tea cups taken out by the cup taking system to the cup filling station, and a second conveying device A for conveying the tea cups in the first conveying device A to the capping system I. a conveying device B, a finished product conveying device J for conveying the finished milk tea cups out, and a third conveying device C for transferring the milk tea cups in the second convey...

Embodiment 2

[0158] The difference between this embodiment and Embodiment 1 is that: the milk tea cup conveying drive mechanism includes a drive cylinder, the cylinder body of the drive cylinder is installed on the first frame 1a, and the telescopic rod of the drive cylinder is connected to the conveying seat 3- 1 connection.

Embodiment 3

[0160] see Figure 54 The difference between this embodiment and Embodiment 1 is that a plurality of liquid raw material storage boxes 3-1g can share a set of liquid raw material conveying mechanism 5g, and only need to set electromagnetic reversing valve 5-1g in the conveying pipe 5-1g. 3g and other hydraulic components, that is, the liquid raw materials in multiple liquid raw material storage boxes 3-1g can be extracted individually.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com