Explosion-proof plate feeding device

A technology of explosion-proof sheet and feeding belt, which is applied in the direction of conveyor control device, transportation and packaging, conveyor, etc., can solve the problems of manual participation, complex structure, and many processes, and achieve simplified structure, low cost and high precision of cylinder expansion and contraction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

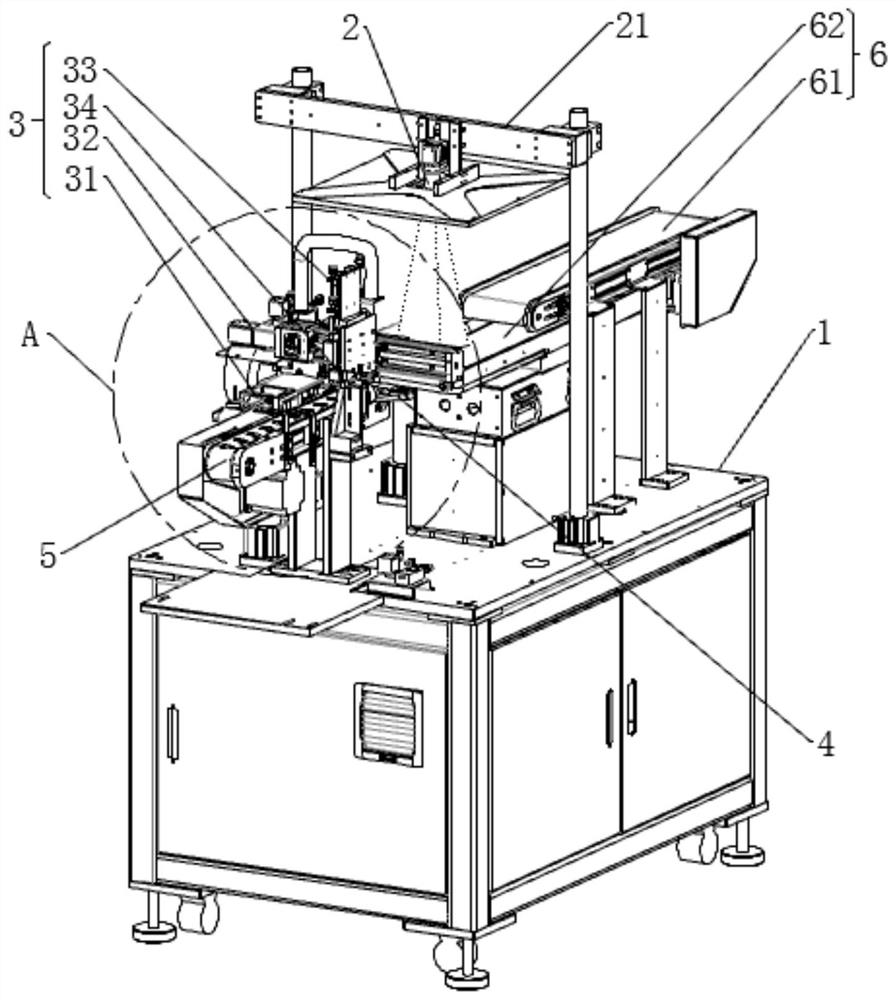

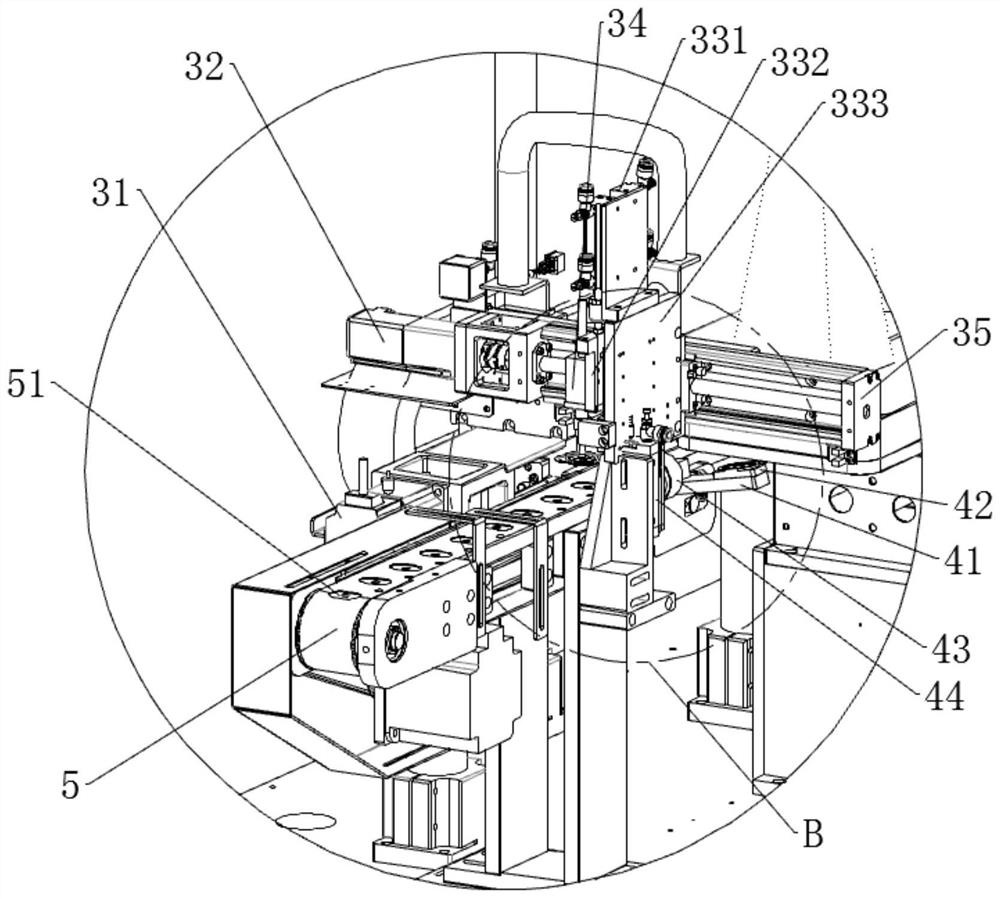

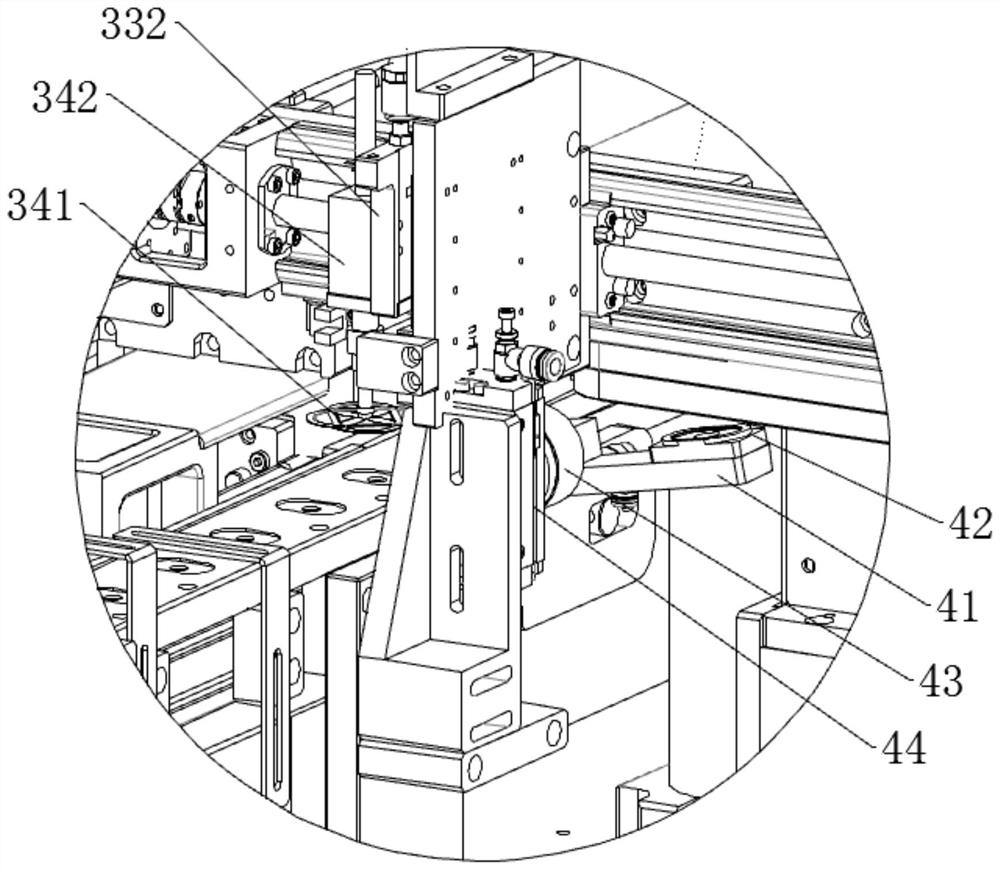

[0029] Such as figure 1 , figure 2 , image 3 As shown, in this embodiment, the explosion-proof plate feeding device is supported by the frame 1, and the conveyor belt 6 and the feeding belt 5 are installed on the top surface of the frame from front to back in sequence, and are supported by a door frame type first bracket 21 above the end of the conveyor belt. The vision system 2 is installed on the beam of the door frame, which can be selected from the common industrial camera identification and positioning system on the market, or the camera identification and positioning system. The camera or video camera is directly fixed under the beam to capture the information of the explosion-proof sheet on the conveyor belt, with the purpose of distinguishing the conveyor belt. The front and back of the explosion-proof disk and its position.

[0030] Explosion-proof plate grasping mechanism 3 includes the first X-direction linear displacement mechanism 32, the Y-direction linear di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com