Iron tailing-based building block and preparation method thereof

A technology of iron tailings and iron tailings powder, which is applied in the field of building materials, can solve the problems of high alkalinity and unfavorable survival of aquatic animals and plants, and achieve the effects of high utilization rate, less physical and chemical interaction, and good designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

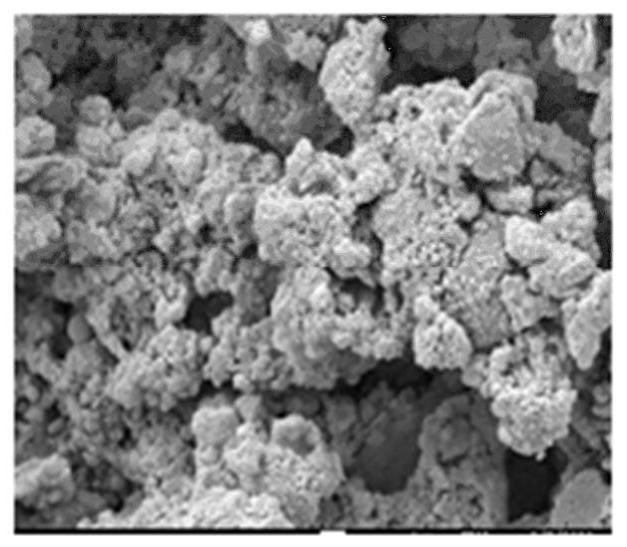

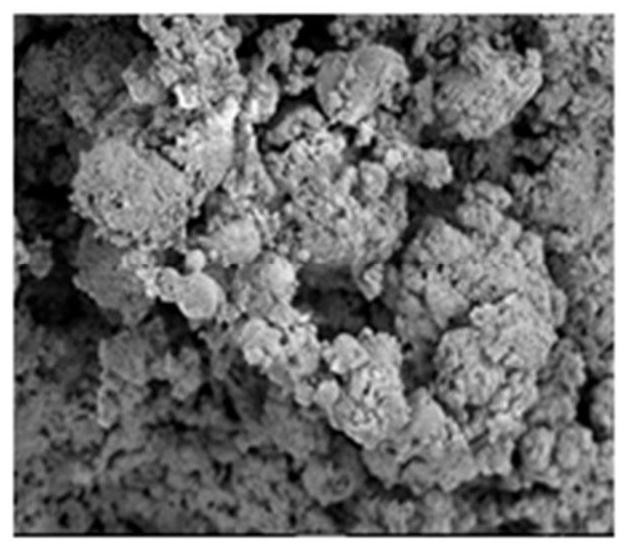

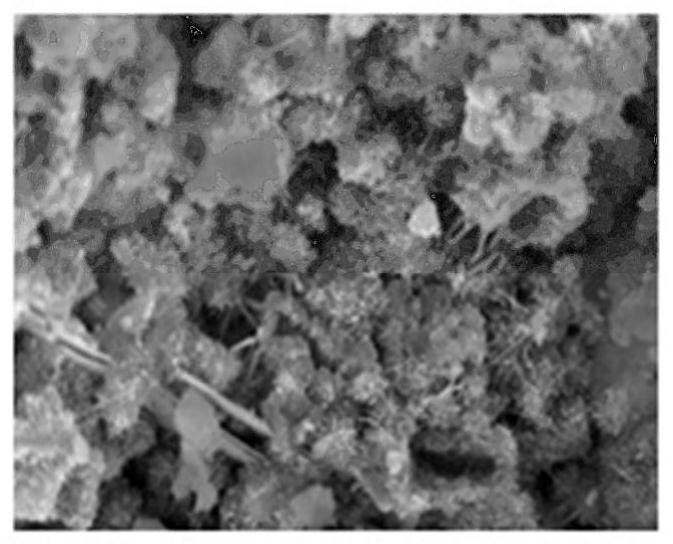

Image

Examples

preparation example Construction

[0087] A method for preparing an iron tailings-based block comprises the following steps.

[0088] Step 1. Weighing: According to the set ratio, weigh the pretreated residual slurry, iron tailings powder, iron tailings sand, cationic starch and mixing water in sequence, and add them to the wheel mill mixer in sequence.

[0089] Step 2, wheel milling for 3-10 minutes.

[0090] Step 3. Forming: The mixed raw materials are pressed and formed by wheel milling to form a hollow block blank; wherein, the forming pressure is 30-50 MPa, and the pressure is kept for 30-60 seconds.

[0091] The design of the above molding pressure and the design of Blaine’s specific surface area and fineness modulus in the raw materials will make the pretreated residual slurry, iron tailings powder, iron tailings sand, cationic starch and mixing water reach the optimum under the designed pressure. The contact surface is conducive to sufficient contact hardening reaction and makes the structure denser. ...

Embodiment 1

[0102] A method for preparing an iron tailings-based block comprises the following steps.

[0103] Step 1. Weighing: According to the set ratio, weigh 20 parts of pretreated residual slurry, 15 parts of iron tailings powder, 120 parts of iron tailings sand, 2 parts of cationic starch and 16 parts of mixing water, and add them to the wheel mill in sequence Mixer; wherein, the Blaine specific surface area of the pretreated residual slurry is 400m 2 / kg; Blaine specific surface area of iron tailings powder is 400m 2 / kg; the fineness modulus of the iron tailings sand is 2.0; the mixing water adopts the moisture content of the pretreated residual slurry during the dehydration pretreatment;

[0104] Step 2, wheel milling for 10 minutes;

[0105] Step 3. Forming: The mixed raw materials are pressed and formed by wheel milling to form a hollow block blank; wherein, the forming pressure is 30 MPa, and the pressure is kept for 30 seconds.

[0106] Step 4, standing still: stack t...

Embodiment 2

[0109] A method for preparing an iron tailings-based block comprises the following steps.

[0110] Step 1. Weighing materials: according to the set ratio, weigh 10 parts of pretreated residual slurry, 20 parts of iron tailings powder, 60 parts of iron tailings sand, 0.6 parts of cationic starch and 5 parts of mixing water, and add them to the wheel mill in sequence Mixer; wherein, the Blaine specific surface area of the pretreated residual slurry is 450m 2 / kg; Blaine specific surface area of iron tailings powder is 450m 2 / kg; the fineness modulus of iron tailings is 1.8; the mixing water adopts the moisture content of the pretreated residual slurry during dehydration pretreatment;

[0111] Step 2, wheel milling for 3 minutes;

[0112] Step 3. Forming: Press and form the mixed raw materials by wheel grinding to form a hollow block blank; wherein, the forming pressure is 50 MPa, and the pressure is maintained for 60 seconds;

[0113] Step 4, standing still: stack the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com