Method for concentrating and purifying vinegar

A technology of vinegar and vinegar liquid, which is applied in the field of vinegar production, can solve the problems of vinegar liquid turbidity and troubles in vinegar production and operation, and achieve the effects of good purification of vinegar and convenient concentration and production operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

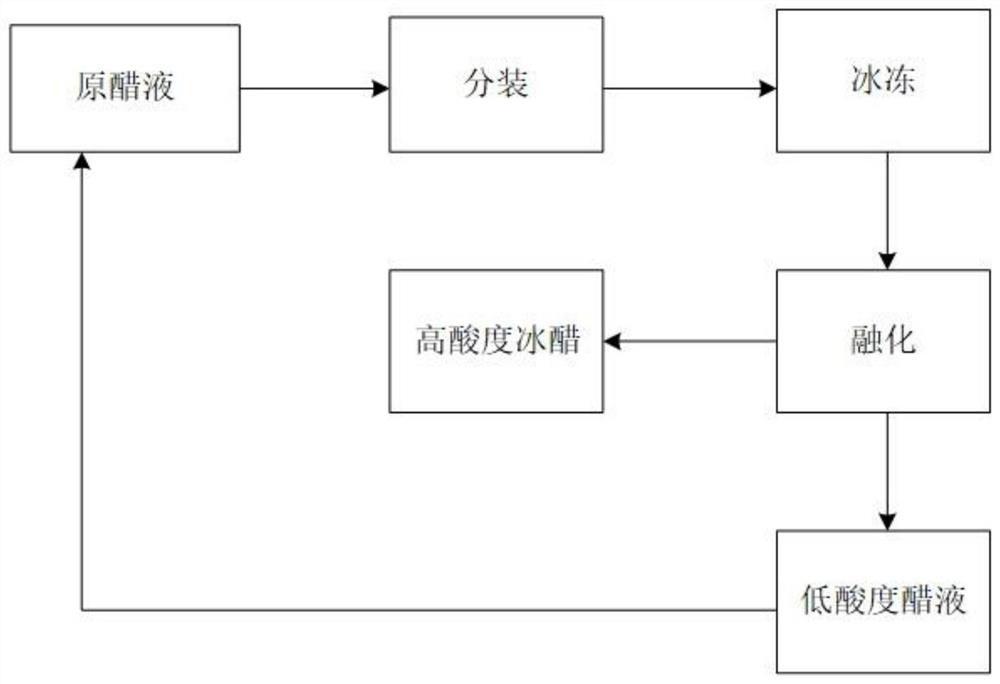

[0023] Embodiment 1, as figure 1 Shown, the method for the concentrated purification of vinegar in the present embodiment may further comprise the steps:

[0024] S1, sub-pack the drenched raw vinegar solution, and pour it into a stainless steel drum with a volume of 10L;

[0025] S2, putting the stainless steel drum with a cover and putting it into a freezer with a temperature of -15°C;

[0026] S3. After freezing for 3 days, the original vinegar liquid is completely frozen into vinegar ice cubes, and the vinegar ice cubes are placed on the ice dripping table to melt the vinegar ice cubes, and the melted ice vinegar solution is collected;

[0027] S4. Detect the acidity of the glacial vinegar solution. When the acidity of the glacial vinegar solution reaches 6 degrees or more, it is collected and stored, and the subsequent glacial vinegar solution that does not reach 6 degrees is collected separately; when it is collected separately, when the subsequent collection After the...

Embodiment 2

[0030] Embodiment 2, as figure 1 Shown, the method for the concentrated purification of vinegar in the present embodiment may further comprise the steps:

[0031] S1, sub-pack the drenched raw vinegar solution, and pour it into a stainless steel drum with a volume of 10L;

[0032] S2, put the stainless steel drum with a cover and put it into a freezer with a temperature of -18°C;

[0033] S3. After freezing for 5 days, the original vinegar liquid is completely frozen into vinegar ice cubes, and the vinegar ice cubes are placed on the ice dripping table to melt the vinegar ice cubes, and the melted ice vinegar solution is collected;

[0034] S4. Detect the acidity of the glacial vinegar solution. When the acidity of the glacial vinegar solution reaches 6 degrees or more, it is collected and stored, and the subsequent glacial vinegar solution that does not reach 6 degrees is collected separately; when it is collected separately, when the subsequent collection After the acidity...

Embodiment 3

[0037] Embodiment 3, as figure 1 Shown, the method for the concentrated purification of vinegar in the present embodiment may further comprise the steps:

[0038] S1, sub-pack the drenched raw vinegar solution, and pour it into a stainless steel drum with a volume of 10L;

[0039] S2, putting the stainless steel drum with a cover and putting it into a freezer with a temperature of -20°C;

[0040] S3. After freezing for 6 days, the original vinegar solution is completely frozen into vinegar ice cubes, and the vinegar ice cubes are placed on the ice dripping table to melt the vinegar ice cubes, and the melted ice vinegar solution is collected;

[0041] S4. Detect the acidity of the glacial vinegar solution. When the acidity of the glacial vinegar solution reaches 6 degrees or more, it is collected and stored, and the subsequent glacial vinegar solution that does not reach 6 degrees is collected separately; when it is collected separately, when the subsequent collection After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com