Long ceramic tile auxiliary paving equipment for brick wall construction

A technology for ceramic tiles and brick walls, which is applied to the field of auxiliary laying equipment for long ceramic tiles for brick wall construction, can solve problems such as low efficiency and cumbersome steps, and achieve the effects of avoiding waste of resources, saving time and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

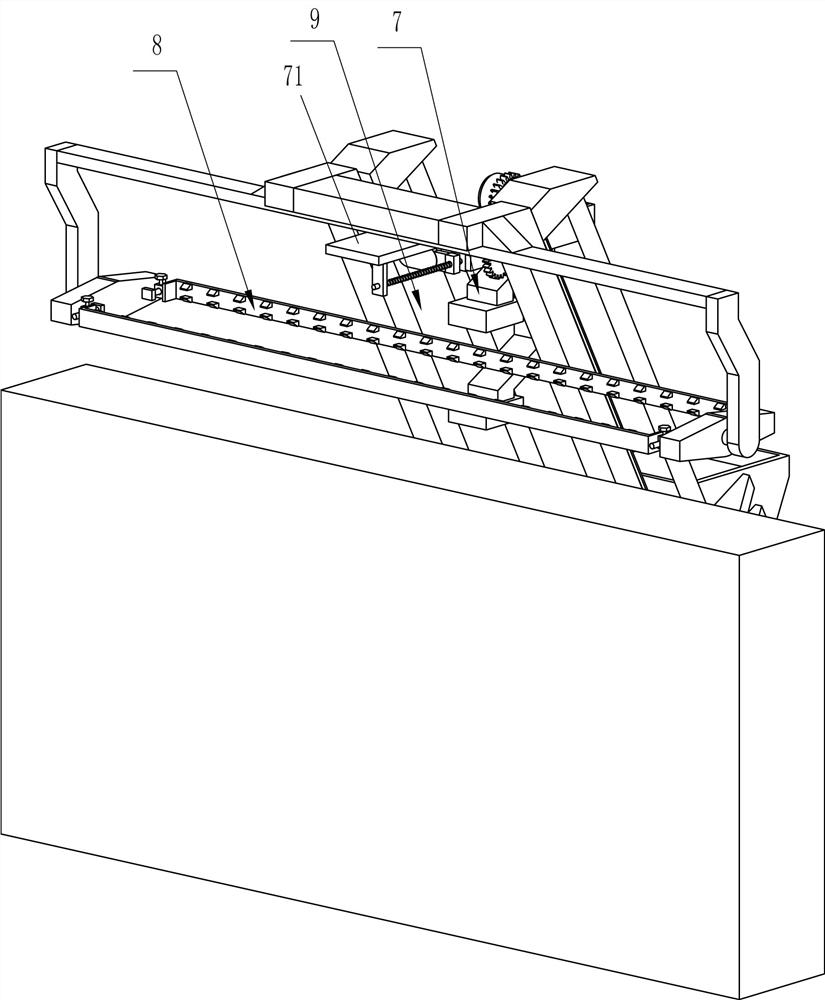

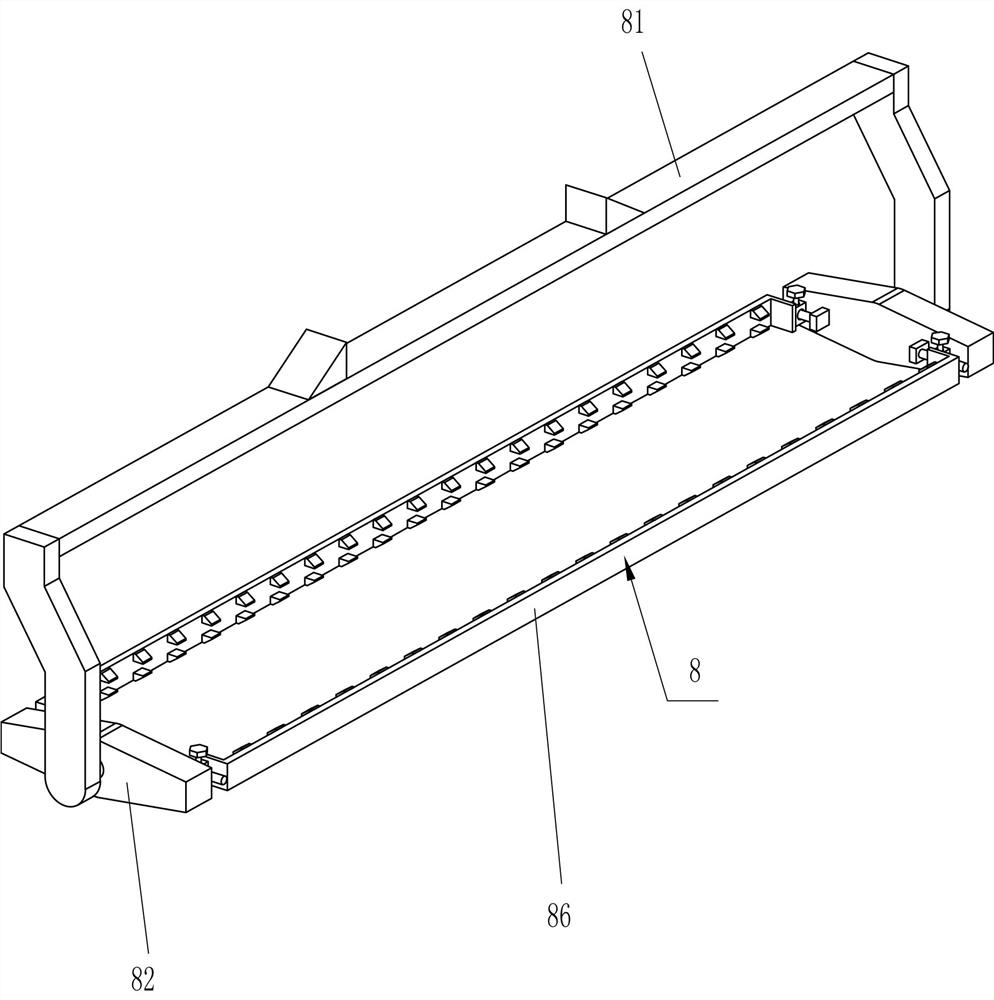

[0032] A long tile auxiliary laying equipment for brick wall construction, such as Figure 1-4 As shown, it includes a mounting frame 1, a universal wheel 2, a first guide rail 3, a first guide sleeve 4, a feeding device 5, a cover opening device 6, a feeding device 7 and a placement device 8, specifically:

[0033] Four sets of universal wheels 2 are connected to the lower side of the installation frame 1, and two sets of first guide rails 3 are connected to the upper side of the installation frame 1. The first guide rails 3 are slidably connected to the first guide sleeve 4, and the first guide sleeve 4 There is a feeding device 5 between them, the lower left side of the feeding device 5 is provided with a cover opening device 6, and the upper left side of the mounting frame 1 is provided with a blanking device 7, the cover opening device 6 can be in contact with the blanking device 7, and the mounting frame 1 The left side is provided with placing device 8.

[0034] When i...

Embodiment 2

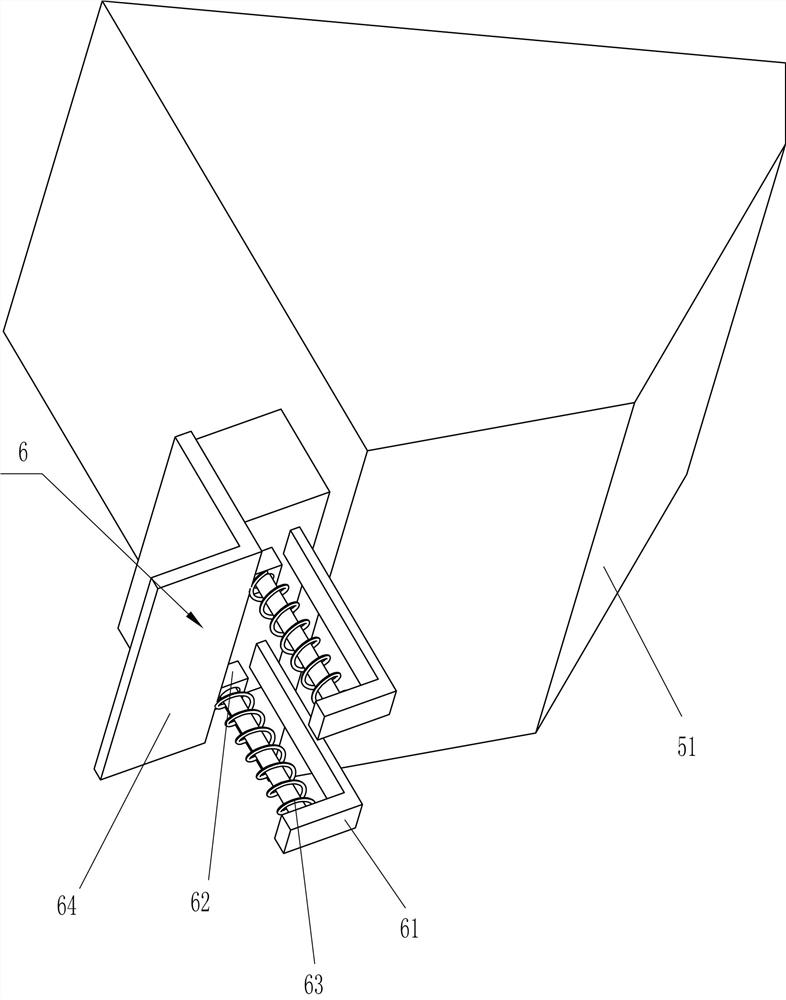

[0036] On the basis of Example 1, such as Figure 5-12 As shown, the feeding device 5 includes a placement bucket 51, a first rotating shaft 52, a belt transmission assembly 53, a moving block 54 and a servo motor 55, specifically:

[0037] A placement bucket 51 is connected between the first guide sleeves 4. The placement bucket 51 is a structure with an opening on the left side. The cover opening device 6 is located on the lower side of the placement bucket 51. The upper left side and the lower right side of the front part of the mounting frame 1 are connected in a rotational manner. There is a first rotating shaft 52, a belt transmission assembly 53 is connected between the first rotating shafts 52, a moving block 54 is connected to the upper side of the belt driving assembly 53, the moving block 54 is connected to the lower side of the placement bucket 51, and a servo is connected to the lower side of the mounting frame 1. The motor 55 and the servo motor 55 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com