Broken ore body recoverable support shield upward double-layer access filling mining method

A technology of approach filling and mining method, which is applied in the direction of filling, ground mining, mining equipment, etc. It can solve the problems of insufficient working space for mechanized equipment, high support and filling costs, and difficult construction techniques, etc., and achieves convenient and segmented Effects of installation and disassembly, reduction of filling and maintenance time, and acceleration of recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The technical solutions of the various embodiments of the present invention will be clearly and completely described below. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them; based on the embodiments of the present invention, those skilled in the art All other embodiments obtained by the skilled person without creative work belong to the protection scope of the present invention.

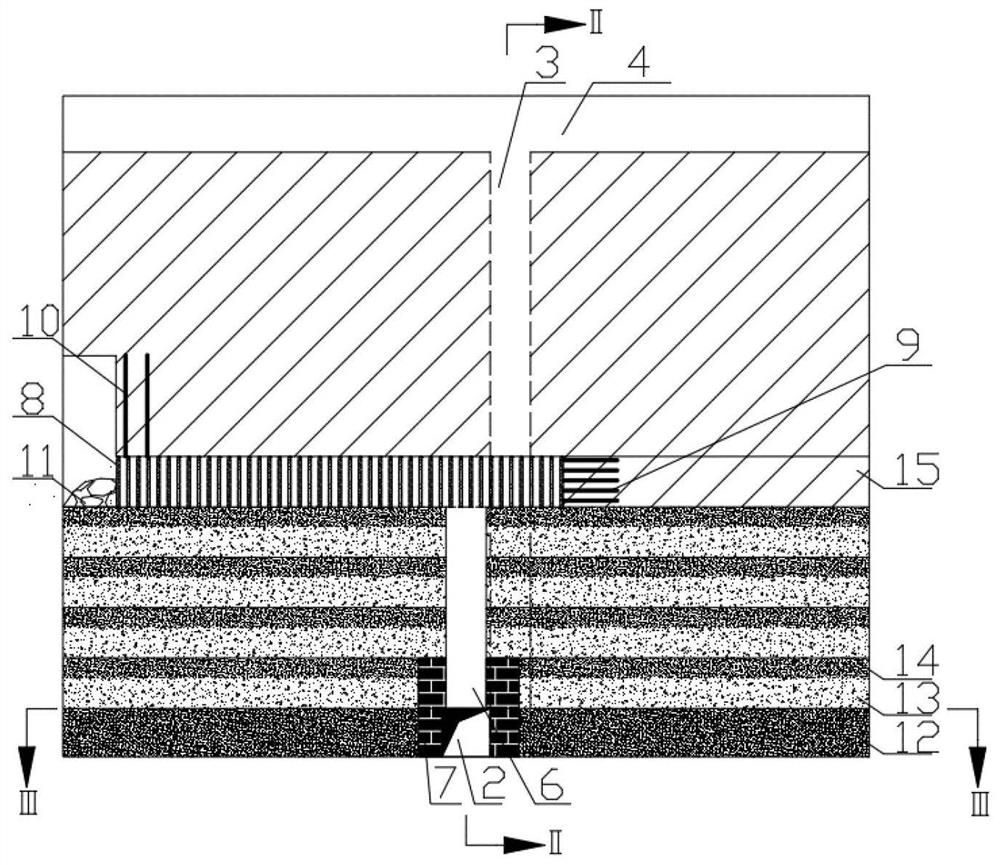

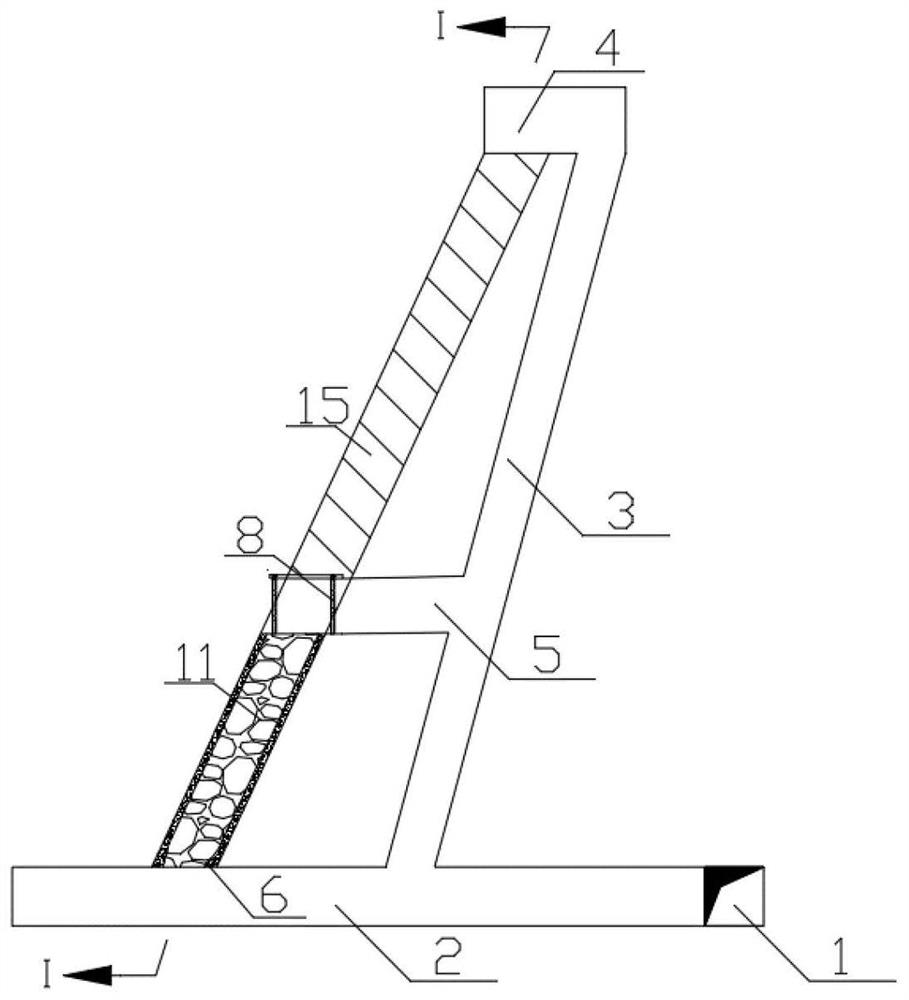

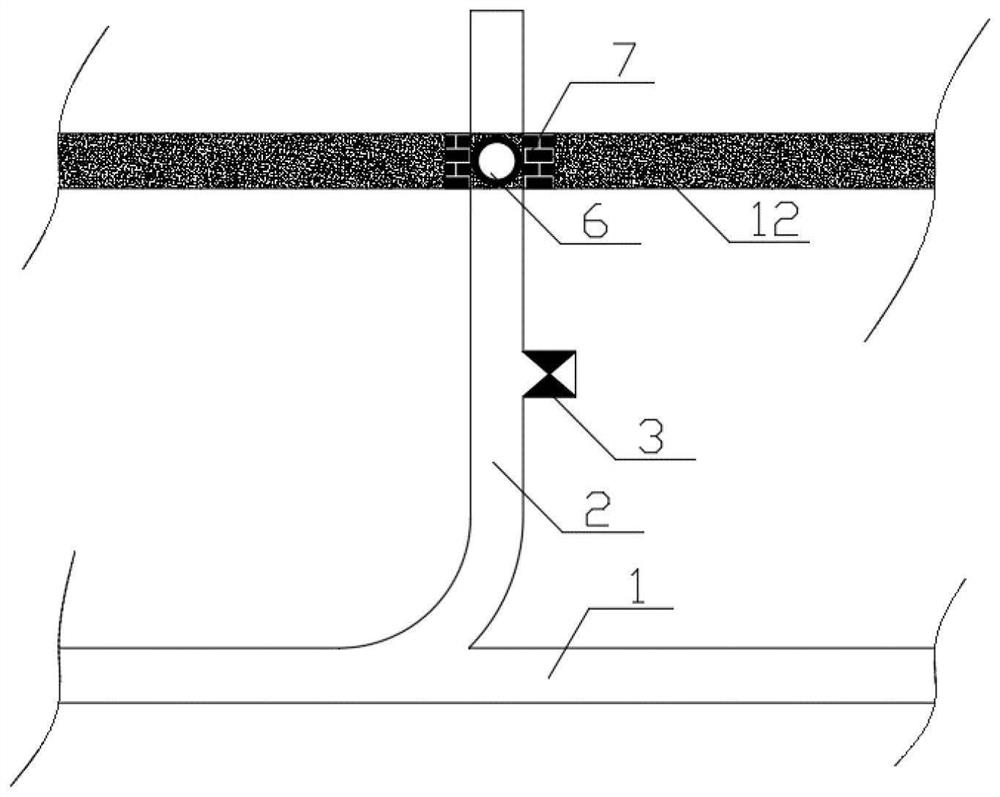

[0038] see Figure 1 to Figure 3 As shown, the layout of the broken ore body stope corresponding to the double layered approach filling mining method provided by the present invention is as follows:

[0039] The stope includes the transportation roadway 1 outside the middle vein, and the ore-loading passageway 2 excavated from the central part of the transportation roadway outside the middle vein; One end of the tunnel communicates with the patio chamber 4 on the top, and the layered contact roadway 5 is constructed by the pedestria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com