Method for testing permeability characteristic and bearing capacity of deep-buried high-pressure grouting tunnel surrounding rock

A technology of bearing capacity and permeability characteristics, which is applied in the field of testing the permeability characteristics and bearing capacity of surrounding rocks in grouting fissures in deep-buried high-pressure tunnels. Effects of Sex and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

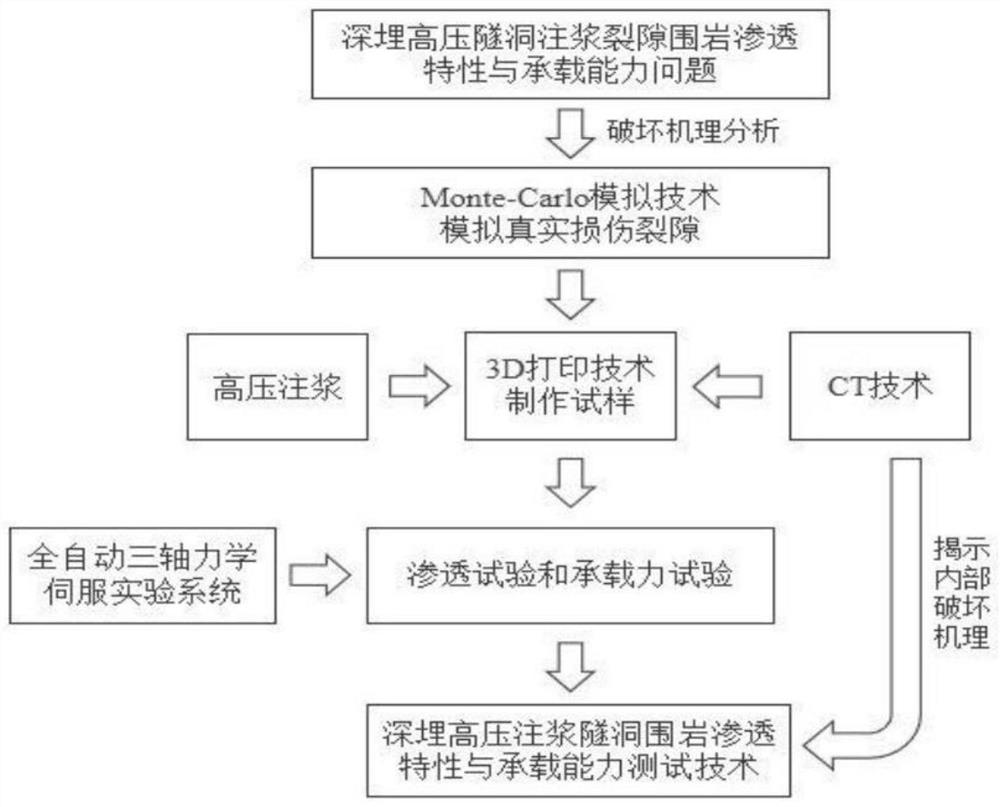

[0028] Such as Figure 1 to Figure 3 As shown, the method for testing the permeability characteristics and bearing capacity of the surrounding rock of the deep-buried high-pressure grouting tunnel of the present invention comprises the following steps:

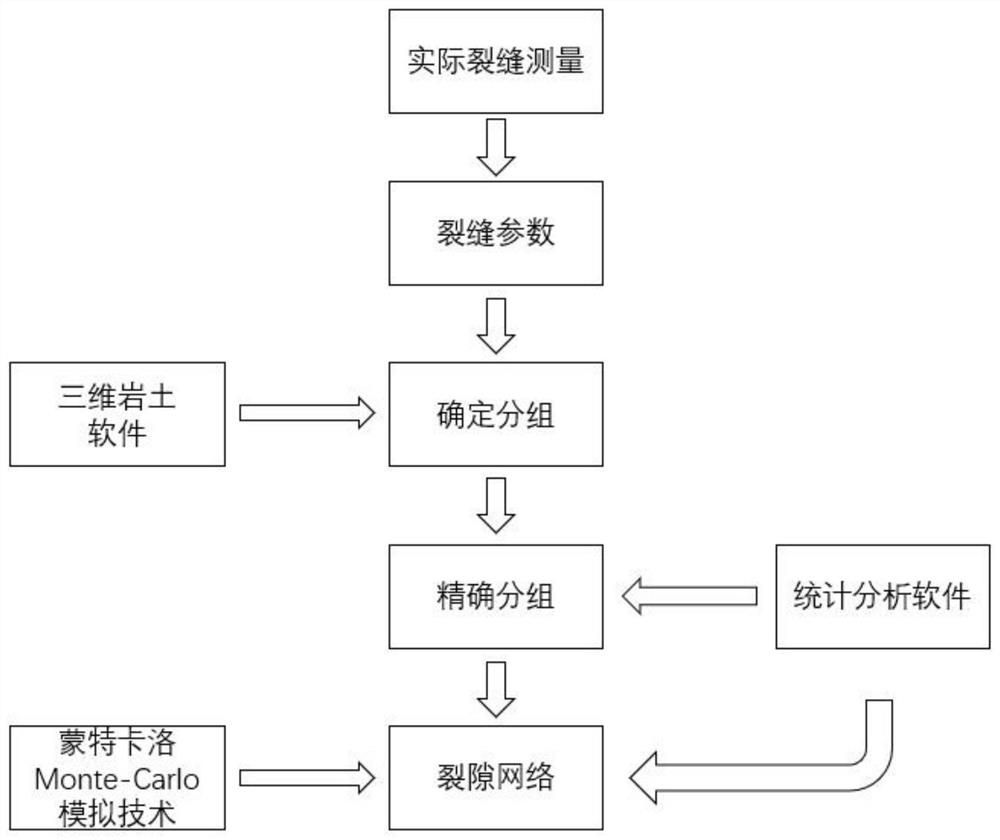

[0029] (1) The Monte-Carlo simulation method is used to simulate the surrounding rock damage crack network excavated by the deep-buried high-pressure tunnel, and the actual cracks are measured to obtain the inclination angle, position, radius, and crack width crack parameters, which are determined by 3D geotechnical software The number of groups, use statistical analysis software to carry out precise grouping and determine the type of distribution function, and write a program to generate a fracture network;

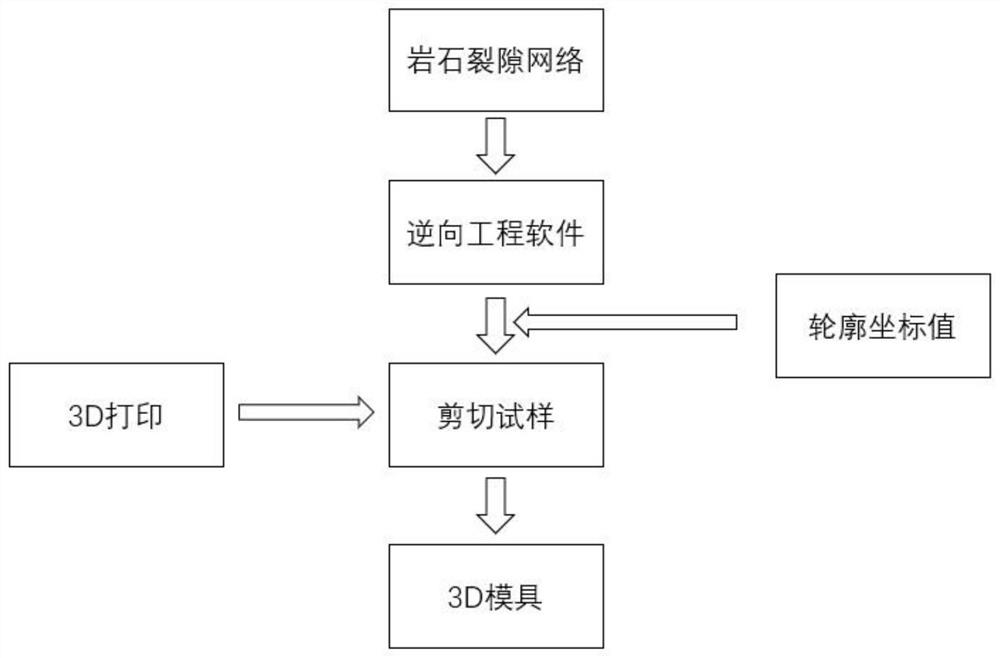

[0030] (2) The rock fracture network constructed based on Monte-Carlo simulation generally adopts reverse engineering software, using existing samples, and obtains the outline through the Monte-Carlo method and the fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com