A motor with retractable shaft extension

A shaft extension and axial technology, applied in the field of motors with retractable shaft extension, can solve the problems of low general performance of the motor and unique shaft extension length, etc., and achieve the effects of low production cost, enhanced versatility, and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

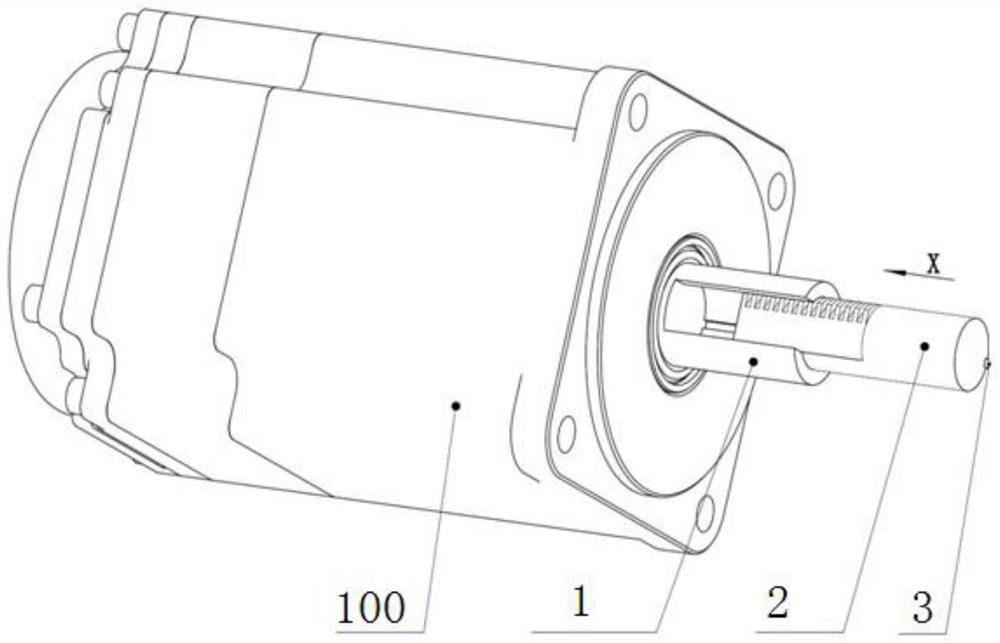

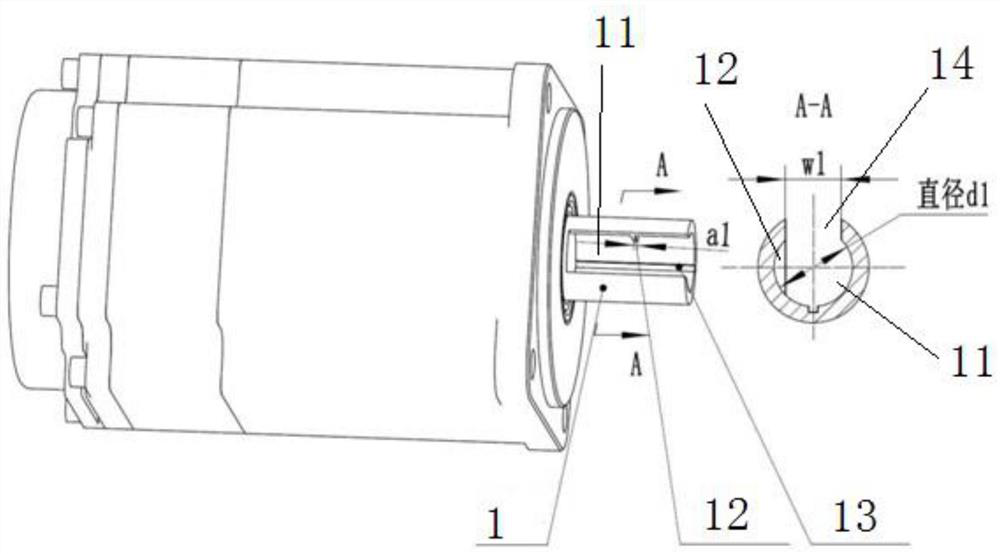

[0037] like Figure 1-5 As shown, the present invention provides a motor 100 with a retractable shaft, which includes:

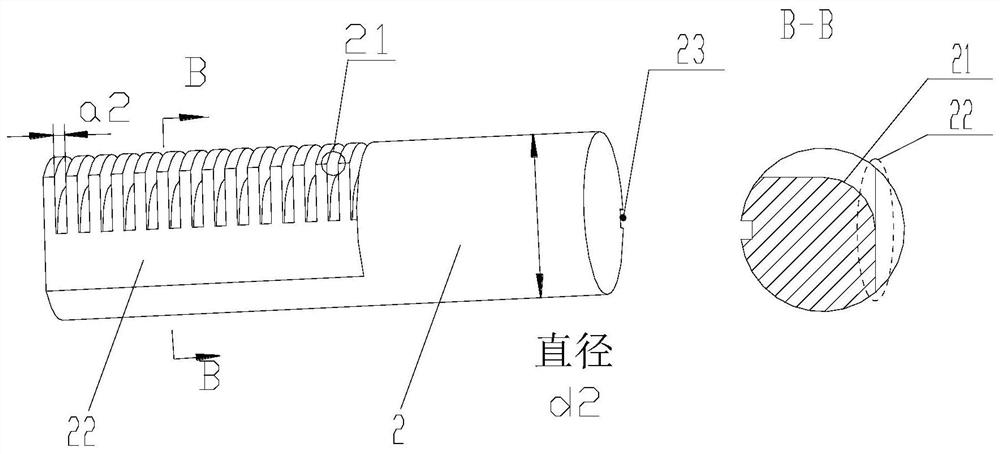

[0038] Shaft body 1 and shaft extension 2: The shaft body 1 is a hollow structure including a first inner cavity 11, and the shaft extension 2 can be inserted into the first inner cavity 11 and can be inside the first inner cavity 11 The cavity 11 moves relative to the shaft body 1 in the axial direction, and at least two clamping positions in the axial direction can be formed between the shaft extension 2 and the shaft body 1;

[0039] Alternatively, the shaft extension 2 is a hollow structure including a second inner cavity (not shown in the figure), and the shaft body 1 can be inserted into the second inner cavity and can be inserted into the second inner cavity The cavity moves relative to the shaft extension 2 in the axial direction, and at least two clamping positions in the axial direction can be formed between the shaft body 1 and the shaft extensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com