Pastry making system with parallel linkage

A parallel linkage mechanism and manufacturing system technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of changing actions, difficult cleaning, high price, etc., and achieve easy sweeping, easy switching, and scale big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

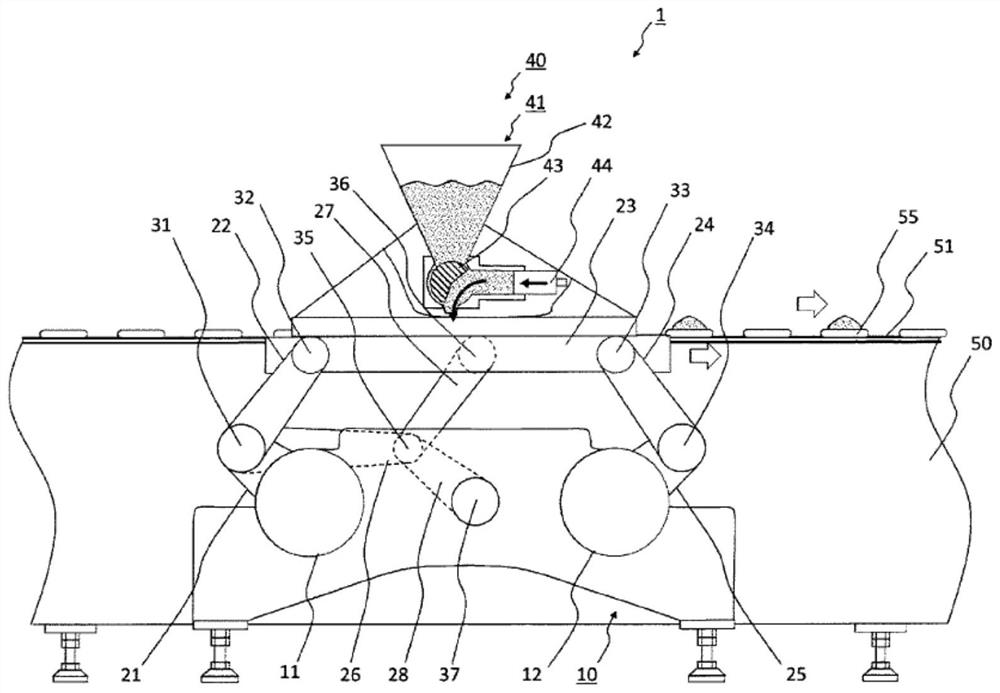

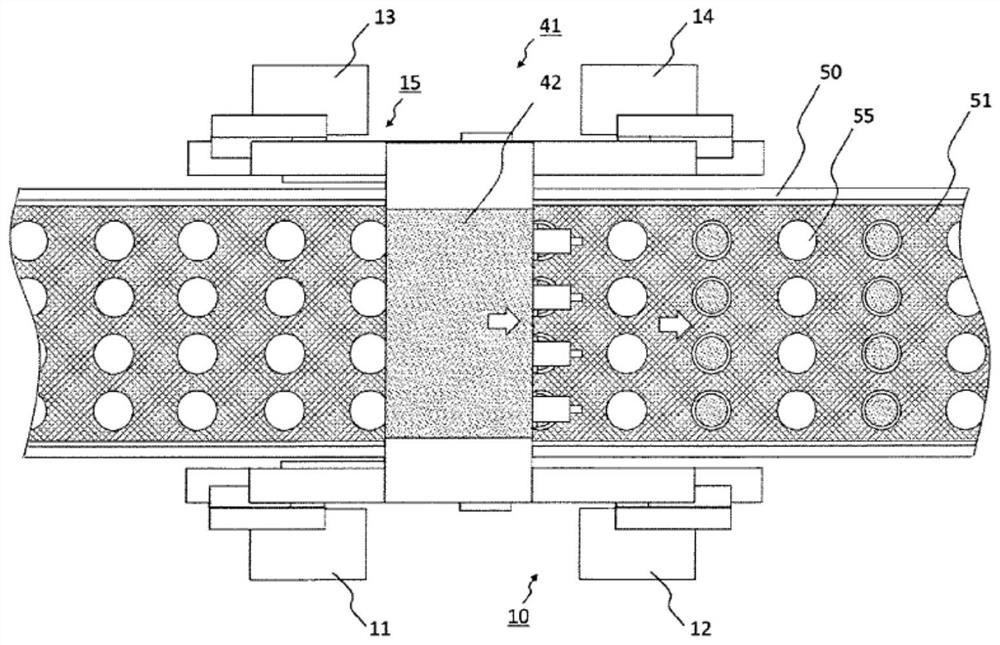

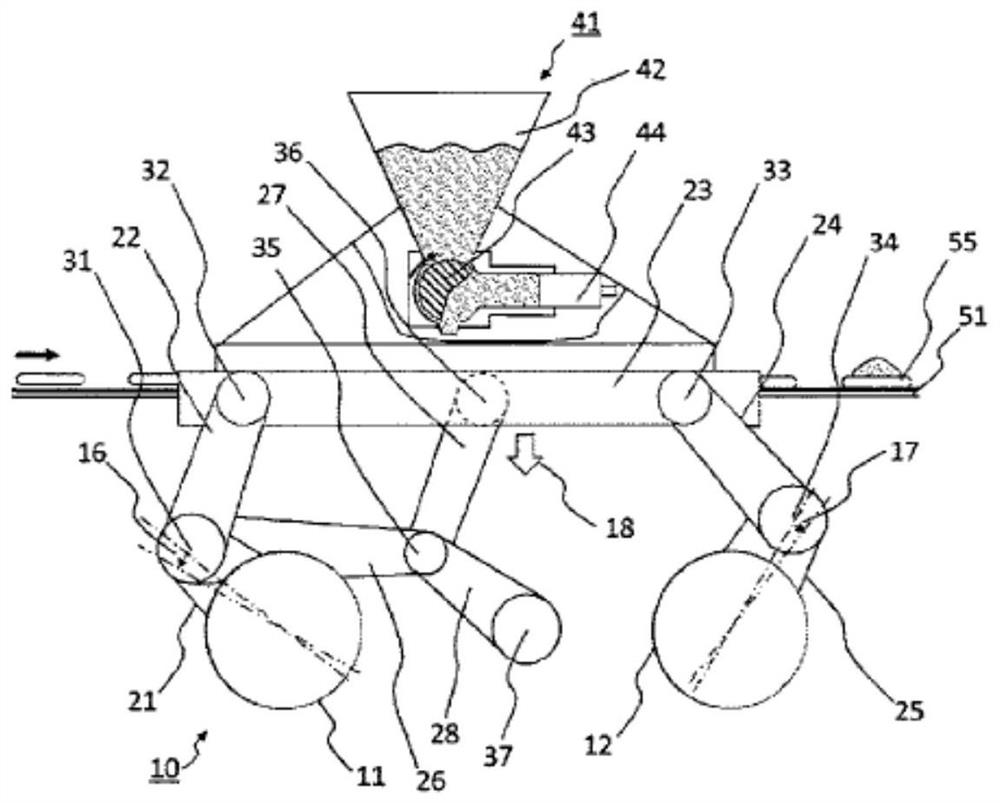

[0042] Next, a specific example of an aspect for implementing the confectionery manufacturing system having a parallel link mechanism according to the present invention will be described in detail with reference to the drawings.

[0043] figure 1 is a schematic view showing a stand and a confectionery unit of a confectionery production system having a parallel linkage mechanism according to an embodiment of the present invention, figure 2 is showing figure 1 Schematic top view of the bench and pastry making unit.

[0044] refer to figure 1 and figure 2 , the pastry manufacturing system 1 of the embodiment of the present invention has: two stands (10, 15), and it is opposite to each other on both sides perpendicular to the conveying direction of conveying device 50, and described conveying device 50 has the function for conveying pastry. Conveyor belt 51 of 55; And pastry making unit 40, it straddles conveying device 50 and is arranged on two stands (10,15) alternatively....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com