Tube bundle type dust and mist remover

A demister and tube-bundle technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem of secondary entrainment of liquid droplets captured by the guide ring, difficulty in controlling the thickness of the liquid film, and affecting dust and fog removal In order to achieve the effect of simple structure, fast construction speed and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

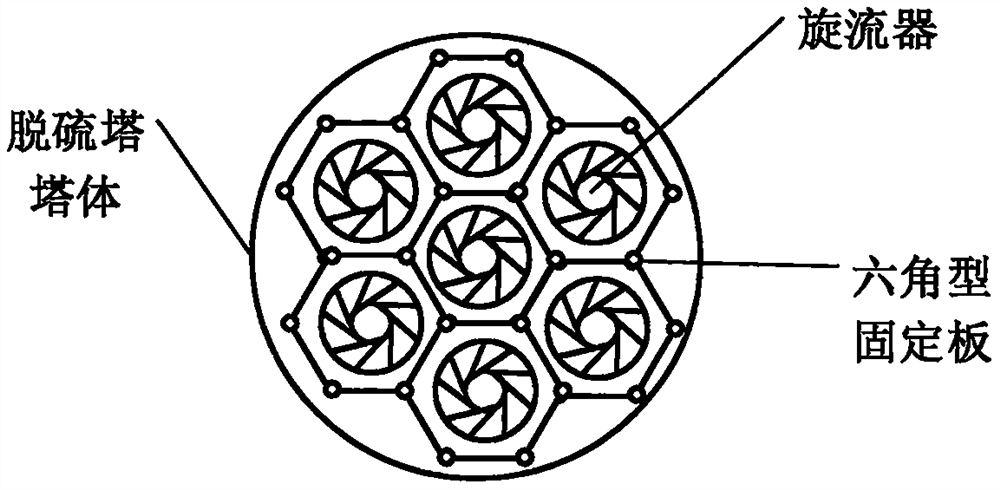

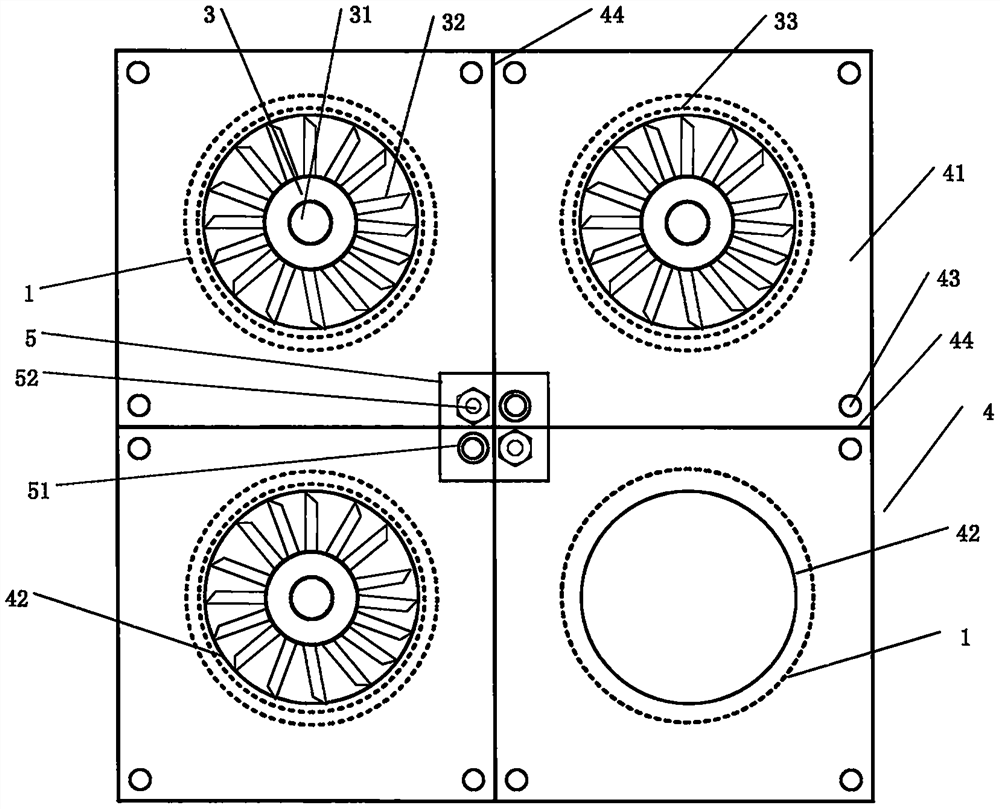

[0104] image 3 It is a schematic diagram of the connection and installation relationship of the tube bundle dust and mist eliminator and the upper fixing plate according to Embodiment 1 of the present invention. In Embodiment 1, a traditional tube bundle defogger is used, and the fixtures or components involved in its installation are optimally designed.

[0105] image 3 It shows a schematic top view of the structure after the upper fixing plate is installed in Embodiment 1, and shows the connection relationship between the upper fixing plate and the tube bundle cylinder of the tube bundle dust and mist collector.

[0106] Such as image 3 As shown, tube bundle cylinder 1 with opening diameter D=400mm and wall thickness 0.5cm is installed in advance with cyclone 3 and other tube bundle dust and fog removal components, and four tube bundle cylinders 1 are positioned in the desulfurization device according to the design requirements. The 4 corners are symmetrically opened w...

Embodiment approach 2

[0109] Figure 4-9 It is a schematic diagram of the connection and installation relationship of the tube bundle dust and mist eliminator and the upper and lower fixing plates according to Embodiment 2 of the present invention. The difference from Embodiment 1 is that, in addition to optimizing the design of the fixing devices or components involved in the installation of the tube bundle demisting cylinder, the structure of the gas outlet end of the tube bundle demisting cylinder is also improved.

[0110] Such as Figure 4 As shown, in Embodiment 2, the tube bundle cylinder 1 is assembled from the lower cylinder 11 and the upper cylinder 12, the connecting parts are connected by a butt ring 13 and sealed by a sealant 15, the lower cylinder 11 and the upper cylinder The cylinder contact end surface 14 of the body 12 is sealed by a sealant, and the butt ring 13 is fixed with bolts between the lower cylinder 11 and the upper cylinder 12 (not shown in the figure).

[0111] Such ...

Embodiment approach 3

[0122] Figures 10-14 It is a schematic diagram of a three-stage cyclone tube bundle dust and mist removal cylinder structure and related cyclone structure, which is the core component of the tube bundle dust and mist eliminator according to Embodiment 3 of the present invention. The difference from Embodiment 2 is that in Embodiment 3, the internal defogging components of the tube bundle defogging cylinder 1 are further improved, and the tube bundle cylinder 1 adopts a single-stage defogging cylinder.

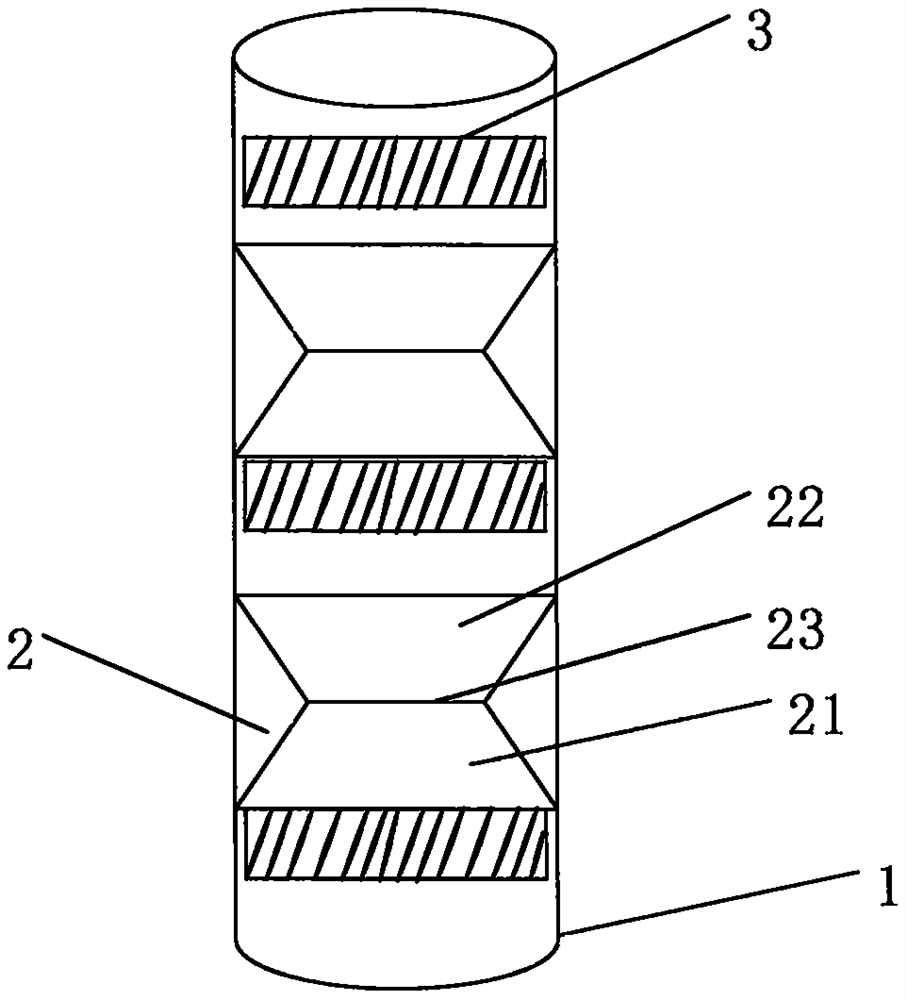

[0123] Such as Figure 10 As shown, the tube bundle dust removal and mist removal cylinder with an opening diameter D=400mm and a wall thickness of 0.5cm includes a tube bundle cylinder 1, a confluence and diversion device 2, a primary cyclone 301, a secondary cyclone 302 and a tertiary cyclone flow device 303; the tube bundle cylinder 1 is a hollow cylinder with openings at both ends, and the tube bundle cylinder 1 is coaxially arranged in sequence from bottom to top with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com