A production process for steel wire non-woven fabric suspenders

A production process and non-woven technology, applied in belts, applications, household appliances, etc., can solve the problems of glue environmental pollution, uneven cooling, poor cooling efficiency, etc., to improve product quality, high production efficiency, and improve cooling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

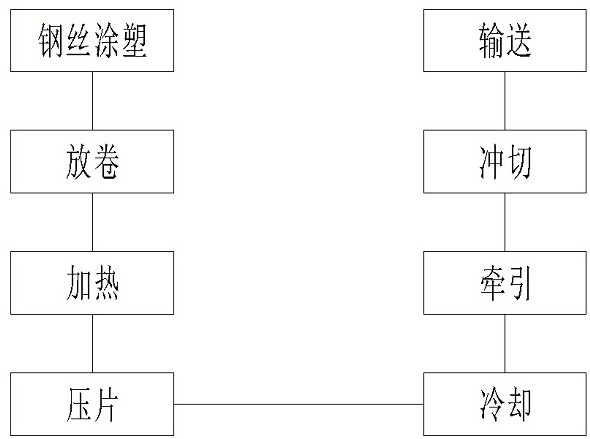

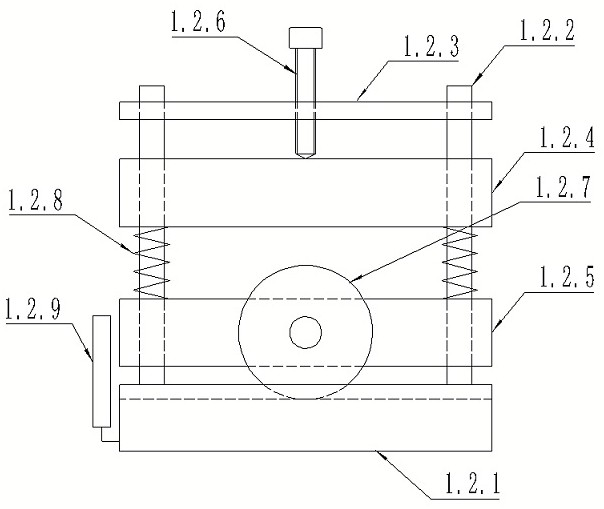

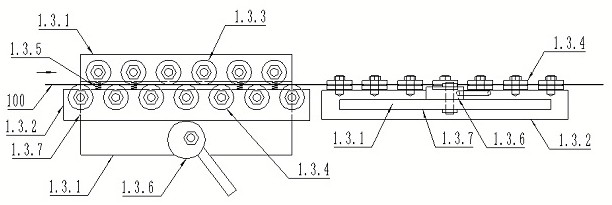

[0051] see Figure 1-16 , the invention relates to a production process for a steel wire non-woven fabric sling, the production process for the steel wire non-woven sling is realized based on a steel wire non-woven sling production line, the steel wire non-woven The cloth sling production line includes steel wire plastic coating system, unwinding mechanism, heating device, tablet pressing mechanism, cooling device, tractor, punching device and conveying device; the steel wire plastic coating system, unwinding mechanism, heating device, pressing The sheet mechanism, cooling device, tractor, punching device and conveying device are arranged in sequence;

[0052] The steel wire plastic coating system includes a feeding frame, a pressing mechanism, a straightening mechanism, a preheating device, a plastic coating mechanism, a water cooling device, a first tractor and a winding mechanism; The straight mechanism, the preheating device, the plastic coating mechanism, the water cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com