Equipment for automatic filling of canned industrial butter

An automatic filling and canning technology, which is applied in packaging and other directions, can solve the problem of slow filling speed of butter, achieve the effect of fast filling speed and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

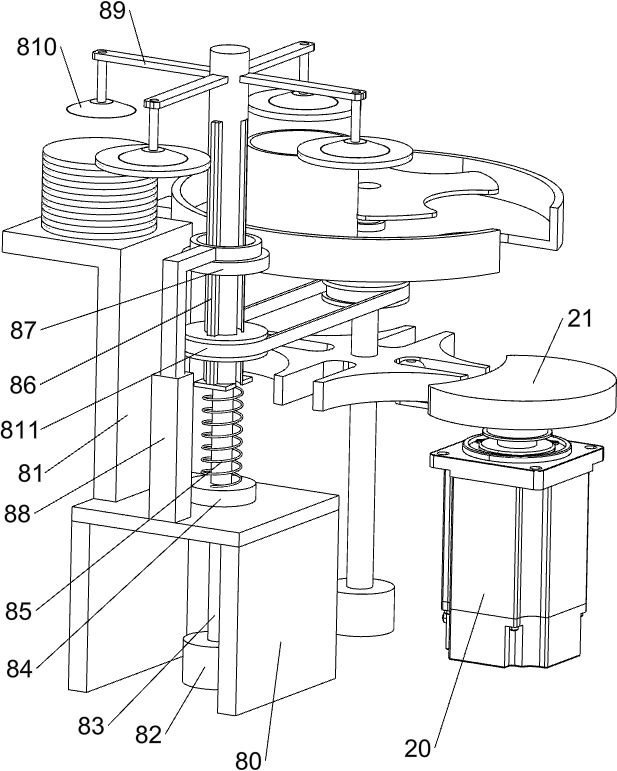

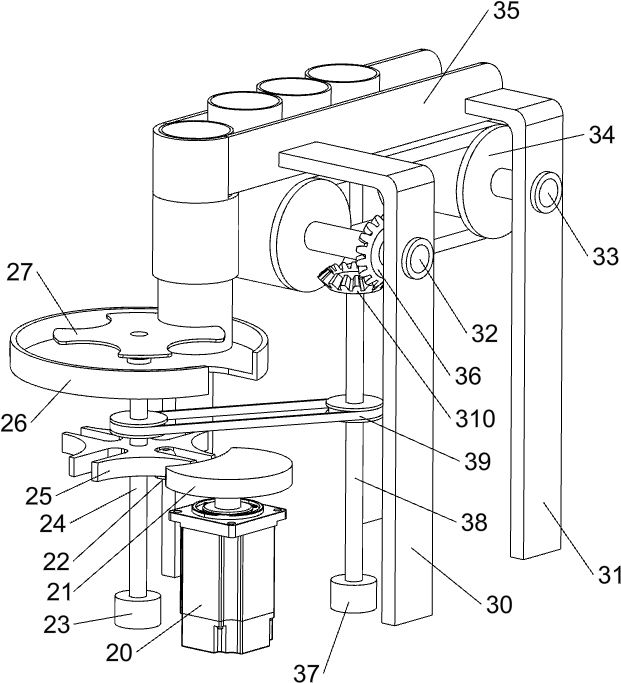

[0021] A device for automatically filling canned industrial butter, such as Figure 1-3 As shown, it includes a base plate 1, a rotating mechanism 2, a feeding mechanism 3, a material box 4, a discharge pipe 5, a rotating plate 6, a handle 7 and a capping mechanism 8, and a rotating mechanism 2 is provided on the left front side of the upper part of the base plate. 1 is provided with a blanking mechanism 3 on the right rear side of the upper part, a material box 4 is provided on the left rear side of the upper part of the bottom plate 1, a rotating plate 6 is provided on the upper part of the material box 4, a handle 7 is provided on the upper right side of the rotating plate 6, and the rotating plate 6 is embedded Type is provided with discharge pipe 5, and base plate 1 upper left middle is provided with gland mechanism 8.

[0022] When the user needs to fill the empty tank with butter, he can use this device. First, open the rotating plate 6 on the material box 4 through the...

Embodiment 2

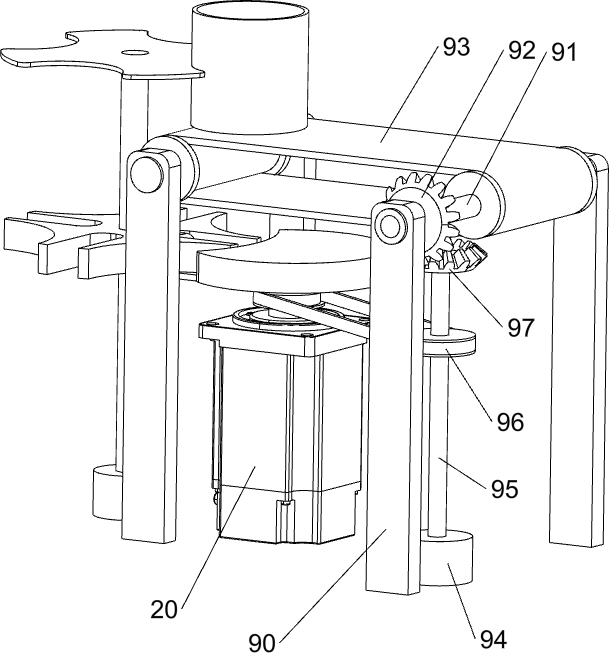

[0030] On the basis of Example 1, such as figure 1 and Figure 4 As shown, a feeding mechanism 9 is also included. The upper left front side of the bottom plate 1 is provided with a feeding mechanism 9. The feeding mechanism 9 includes a third support frame 90, a sixth rotating shaft 91, a third bevel gear 92, a fourth pulley assembly 93, and a third pulley assembly. Seven bearing blocks 94, the seventh rotating shaft 95, the fifth pulley assembly 96 and the fourth bevel gear 97, four third support frames 90 are uniformly arranged on the left front side of the upper part of the bottom plate 1, and the two third support frames 90 on the front side are connected with the rear The sixth rotating shaft 91 is respectively rotated between the two third supporting frames 90 on the side, the fourth pulley assembly 93 is wound between the sixth rotating shaft 91 on the front and rear sides, and the left part of the sixth rotating shaft 91 on the front side is provided with The third b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com