Water-based epoxy curing agent for engineering machinery anticorrosive paint

An anti-corrosion coating, water-based epoxy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings and other directions, can solve the problems of easy shedding of anti-corrosion coatings, no flame retardant ability, unsafe use, etc., and achieve good adhesion performance. and chemical resistance, good color stability, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

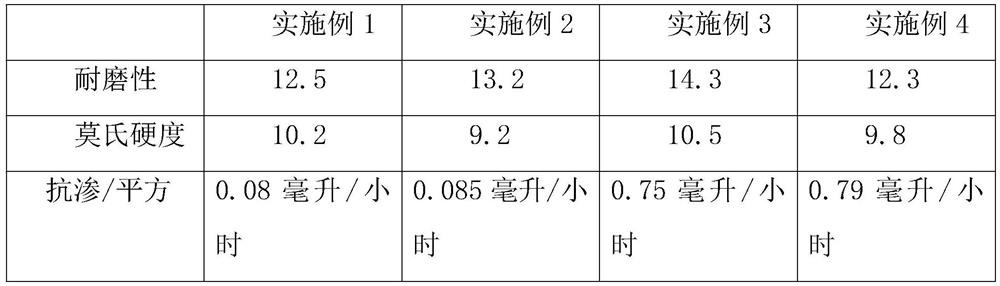

Embodiment 1

[0032] A water-based epoxy curing agent for construction machinery anticorrosion coatings provided by the present invention includes main materials and auxiliary materials, and the main materials include vinyltriamine, polyethylene polyamine, diethylaminopropylamine and trimethylhexamethylene Diamine, the auxiliary material includes antimony trioxide, melamine and polyurethane;

[0033] Further, the mass fractions of ethylenetriamine, polyethylenepolyamine, diethylaminopropylamine and trimethylhexamethylenediamine in the main material are respectively:

[0034] Ethylene triamine: 60 parts, can prevent amine blooming and water spots; good color stability; good adhesive performance and chemical corrosion resistance; wide range of options for curing time and storage time; When used for thermal curing, it has good high temperature performance; it has good chemical corrosion resistance and has good electrical and mechanical properties;

[0035] Polyethylene polyamine: 30 parts, le...

Embodiment 2

[0054] A water-based epoxy curing agent for construction machinery anticorrosion coatings provided by the present invention includes main materials and auxiliary materials, and the main materials include vinyltriamine, polyethylene polyamine, diethylaminopropylamine and trimethylhexamethylene Diamine, the auxiliary material includes antimony trioxide, melamine and polyurethane;

[0055] Further, the mass fractions of ethylenetriamine, polyethylenepolyamine, diethylaminopropylamine and trimethylhexamethylenediamine in the main material are respectively:

[0056] Ethylene triamine: 50 parts, can prevent amine blooming and water spots; good color stability; good adhesive performance and chemical corrosion resistance; wide range of options for curing time and storage time; When used for thermal curing, it has good high temperature performance; it has good chemical corrosion resistance and has good electrical and mechanical properties;

[0057] Polyethylene polyamine: 40 parts, le...

Embodiment 3

[0076] A water-based epoxy curing agent for construction machinery anticorrosion coatings provided by the present invention includes main materials and auxiliary materials, and the main materials include vinyltriamine, polyethylene polyamine, diethylaminopropylamine and trimethylhexamethylene Diamine, the auxiliary material includes antimony trioxide, melamine and polyurethane;

[0077] Further, the mass fractions of ethylenetriamine, polyethylenepolyamine, diethylaminopropylamine and trimethylhexamethylenediamine in the main material are respectively:

[0078] Ethylene triamine: 30 parts, can prevent amine blooming and water spots; good color stability; good adhesive performance and chemical corrosion resistance; wide range of options for curing time and storage time; When used for thermal curing, it has good high temperature performance; it has good chemical corrosion resistance and has good electrical and mechanical properties;

[0079] Polyethylene polyamine: 40 parts, le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com