Weather-resistant master batch UV-7308PP5 as well as preparation method and application thereof

A UV-7308PP5, weather-resistant masterbatch technology, applied in the field of polymer material processing aids, can solve the problems of complex production process and high production cost, and achieve the effects of low cost, cost control, and easy agglomeration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

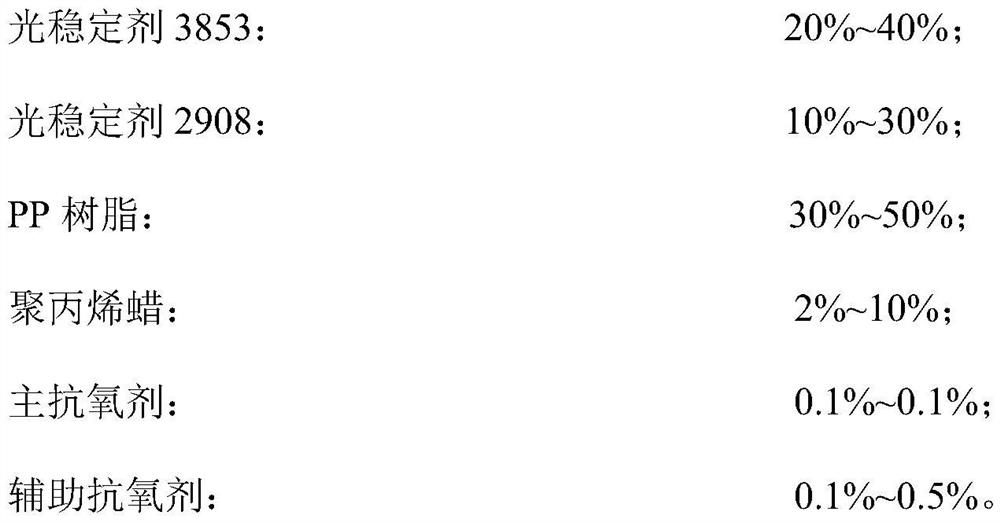

[0037] The weather-resistant masterbatch UV-7308PP5 applied to automotive PP materials in this embodiment includes the following components in mass percentage:

[0038]

[0039]

[0040] The weather-resistant masterbatch UV-7308PP5 applied to automotive PP materials is prepared by the following method:

[0041] (1) The components of light stabilizer 3853 were mixed, and stirred in a high mixer at a stirring speed of 700 rpm for 5 minutes at a temperature of 25°C.

[0042] (2) After the light stabilizer 3853 is heated and turned into a liquid state, it is added through a liquid oil pump and enters a twin-screw extruder for granulation. The temperature of the middle section of the barrel is set at 210-230°C, and the temperature of the front section of the barrel of the extruder is set at 160-170°C. The strips extruded by the twin-screw extruder are cooled by tap water at normal temperature and dried by hot air. Then cut into pellets.

[0043] (3) Pass the obtained granules...

Embodiment 2

[0046] The weather-resistant masterbatch UV-7308PP5 applied to automotive PP materials in this embodiment includes the following components in mass percentage:

[0047]

[0048] The weather-resistant masterbatch UV-7308PP5 applied to automotive PP materials is prepared by the following method:

[0049] (1) The components of light stabilizer 3853 were mixed, and stirred in a high mixer at a stirring speed of 700 rpm for 5 minutes at a temperature of 25°C.

[0050] (2) After the light stabilizer 3853 is heated and turned into a liquid state, it is added through a liquid oil pump and enters a twin-screw extruder for granulation. The temperature of the middle section of the barrel is set at 210-230°C, and the temperature of the front section of the barrel of the extruder is set at 160-170°C. The strips extruded by the twin-screw extruder are cooled by tap water at normal temperature and dried by hot air. Then cut into pellets.

[0051] (3) Pass the obtained granules through a...

Embodiment 3

[0054] The weather-resistant masterbatch UV-7308PP5 applied to automotive PP materials in this embodiment includes the following components in mass percentage:

[0055]

[0056] The weather-resistant masterbatch UV-7308PP5 applied to automotive PP materials is prepared by the following method:

[0057] (1) The components of light stabilizer 3853 were mixed, and stirred in a high mixer at a stirring speed of 700 rpm for 5 minutes at a temperature of 25°C.

[0058] (2) After the light stabilizer 3853 is heated and turned into a liquid state, it is added through a liquid oil pump and enters a twin-screw extruder for granulation. The temperature of the middle section of the barrel is set at 210-230°C, and the temperature of the front section of the barrel of the extruder is set at 160-170°C. The strips extruded by the twin-screw extruder are cooled by tap water at normal temperature and dried by hot air. Then cut into pellets.

[0059] (3) Pass the obtained granules through a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com