Magnetic polymer composite material with efficient photothermal effect and preparation method and application thereof

A polymer material, photothermal effect technology, applied in nanotechnology and other directions, can solve the problems of easy peeling off, poor anti-fouling, and easy damage of the surface hydrophobic anti-icing coating, so as to improve the deicing efficiency, reduce adhesion, and delay icing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

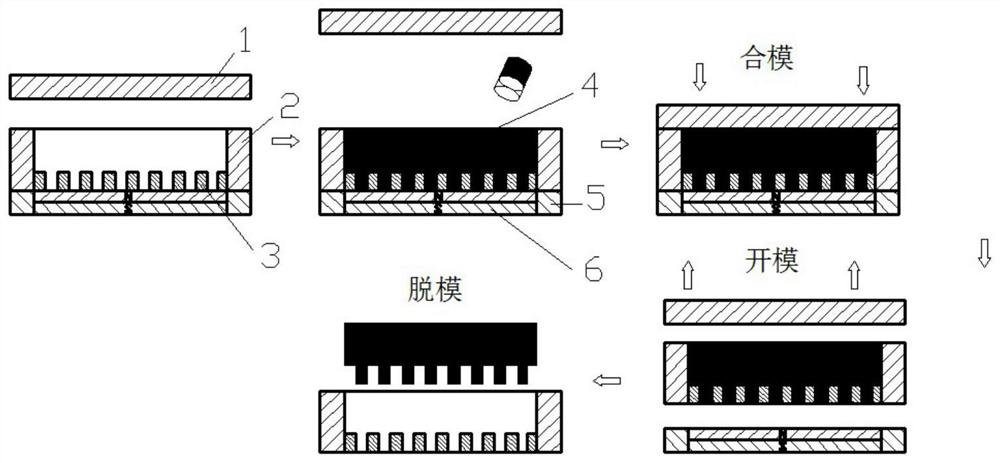

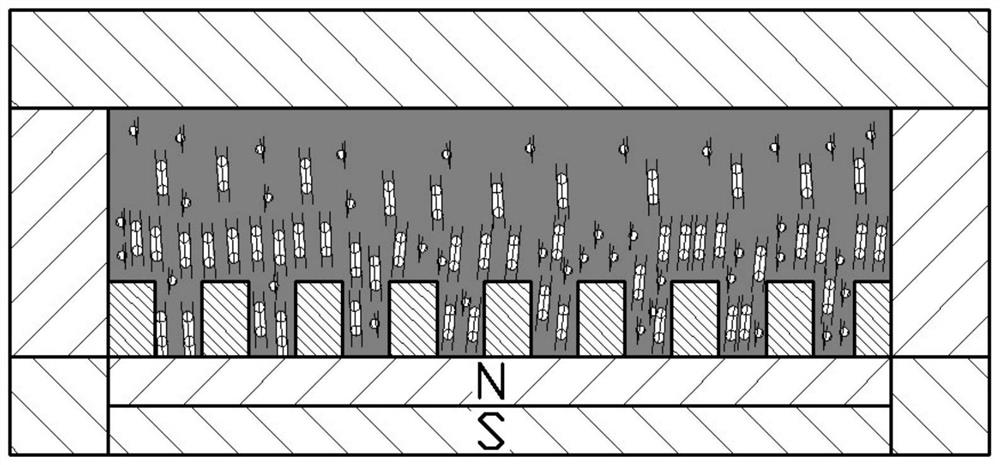

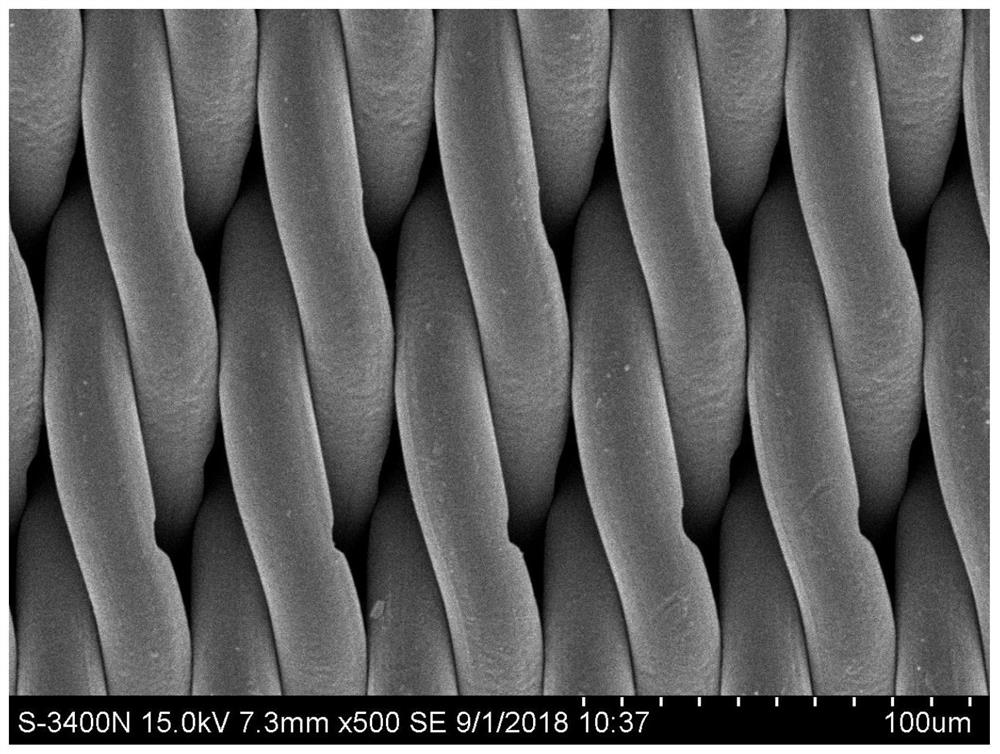

Method used

Image

Examples

Embodiment 1

[0064] (1) Prepare 50 mL of solvent with tetrahydrofuran and absolute ethanol at a volume ratio of 9:1, take out 40 mL and put it into Fe 3 o 4 and volume fraction of 4% triethylamine, the remaining 10mL is added polyphosphazene and dihydroxydiphenyl sulfone with a molar mass ratio of 1:3, slowly drop into 3 o 4 solution, and then complete the wrapping at an ultrasonic frequency of 80 kHz, an ultrasonic temperature of 25° C., and an ultrasonic time of 6 hours to obtain magnetic nanoparticles wrapped with polyphosphazene;

[0065] (2) Purify the wrapped magnetic nanoparticles obtained in step (1) twice and then disperse them in chloroform with a dispersion concentration of 4 mg / mL. Take carbon nanotubes with a mass ratio of 1:5 and disperse them in chloroform with a dispersion concentration of 4 mg. / mL, at an ultrasonic frequency of 60kHz, an ultrasonic temperature of 25°C, and an ultrasonic time of 60 minutes, the material carrier was prepared by mixing and loading;

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Static contact angle | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

| Surface temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap