Directional flow valve with continuous flow adjustment function and control method thereof

A flow valve and flow technology, applied in the direction of earthwork drilling, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problems of precise control of flow, damage to pipelines, sealing, explosion of cylinders, etc., and achieve continuous change of flow , Reduce the effect of hydraulic shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

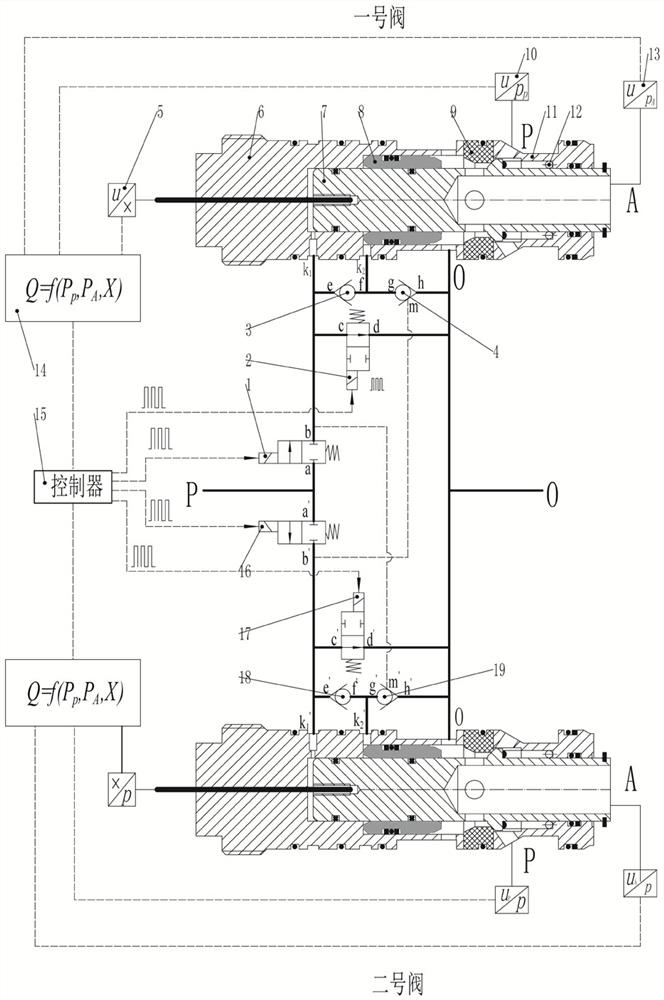

[0023] Below in conjunction with accompanying drawing, the present invention is described in further detail.

[0024] A main valve, including a liquid return valve sleeve 6, a liquid inlet valve core 7, a liquid return valve core 8, a valve seat 9, a liquid inlet valve sleeve 11 and a return spring 12, and the liquid inlet valve core 7 is inserted into the liquid return valve sleeve 6, the left end face of the liquid inlet valve core 7 and the end face of the liquid return valve sleeve 6 form a liquid inlet valve core control chamber, and the liquid inlet valve core control chamber is connected with the liquid inlet and outlet k on the liquid return valve sleeve 6 1 The liquid return valve sleeve 6 is provided with a step inside, and the left end surface of the liquid return valve core 8 forms a liquid return valve core control cavity with the step surface, and the liquid return valve core control cavity is connected with the liquid return valve sleeve 6. Liquid inlet and outl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com