Fan braking circuit

A technology of fans and circuits, applied in pump control, non-variable-capacity pumps, machines/engines, etc., can solve problems such as inability to effectively brake quickly and stop, loss of braking function, and fan design space limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

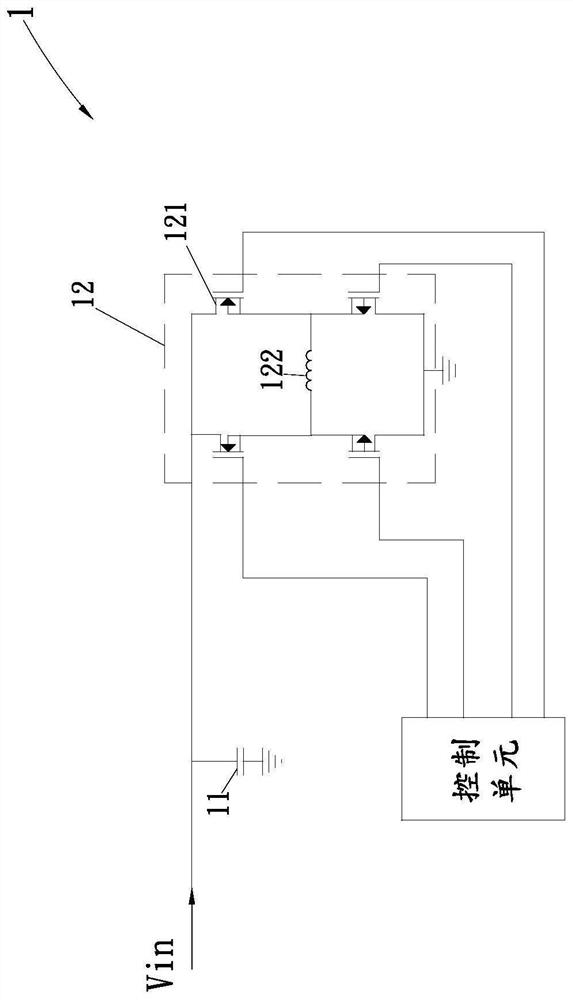

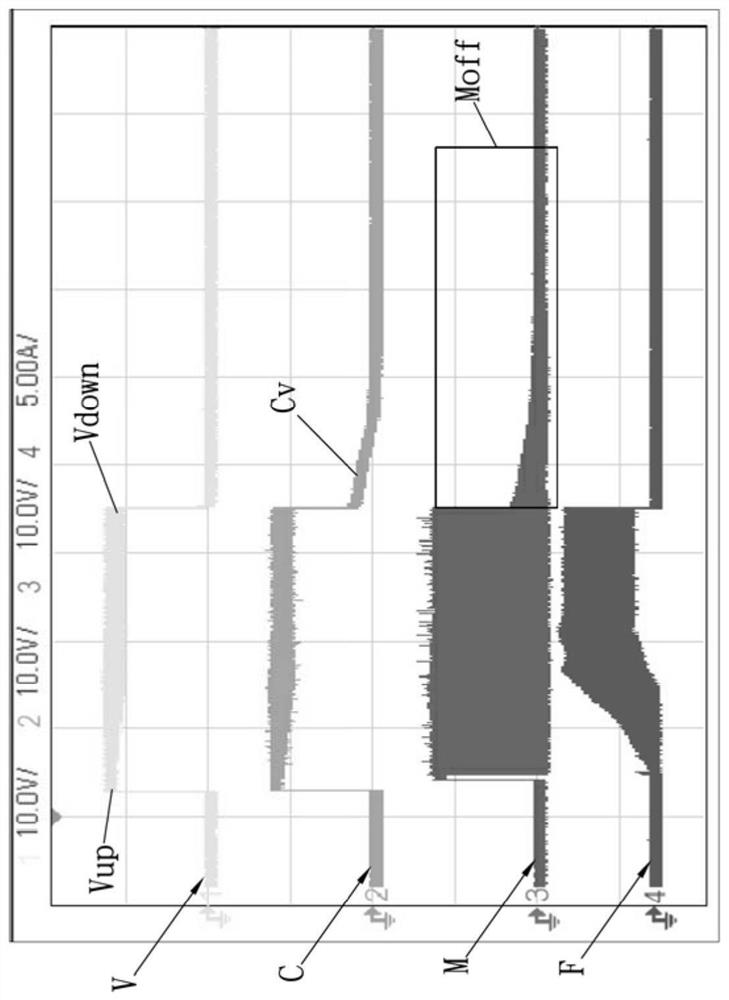

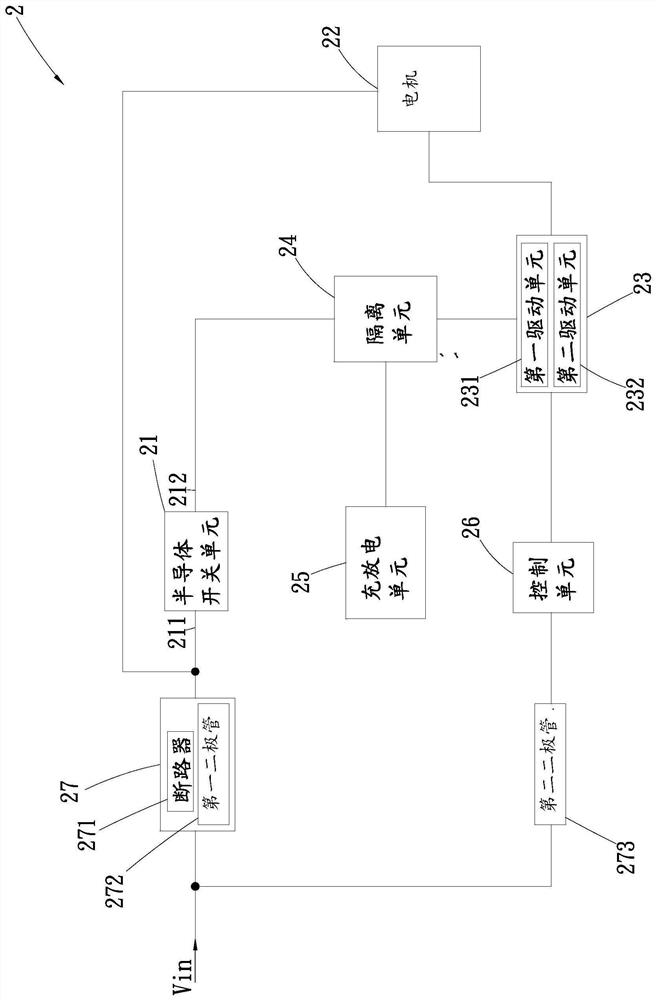

[0026] The present invention provides a fan braking circuit, please refer to Figure 2A It is a block diagram of a fan brake circuit according to an embodiment of the present invention; Figure 2B for the invention Figure 2A The circuit diagram of the fan brake circuit; Figure 2C It is a circuit diagram of a fan braking circuit in a feasible embodiment of the present invention; Figure 3A It is a block diagram of the fan brake circuit of an alternative embodiment of the present invention; Figure 3B for the invention Figure 3A The circuit diagram of the fan brake circuit; Figure 4 It is an actual measurement waveform diagram of the input power supply, the capacitor voltage of the charging and discharging unit, the motor coil voltage and the fan current according to an embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com