Motor controller with laminated busbar heat dissipation structure

A technology of motor controllers and laminated busbars, which is applied to the circuit layout on the support structure, stackable modules, electrical components, etc., can solve the temperature requirements of high-power motor controllers, laminated bus The heat dissipation problem cannot be solved, and the heat dissipation capacity of the copper radiator can be reduced, so as to achieve the effect of lowering the temperature, improving the heat dissipation effect, and the installation method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following specific examples illustrate the present invention in further detail.

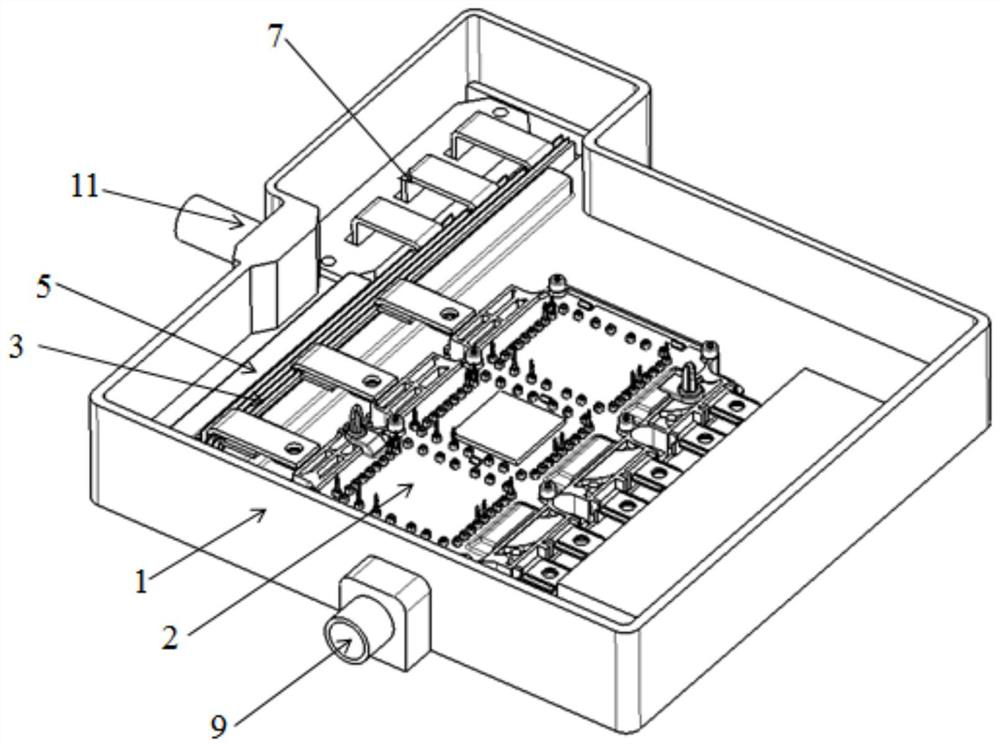

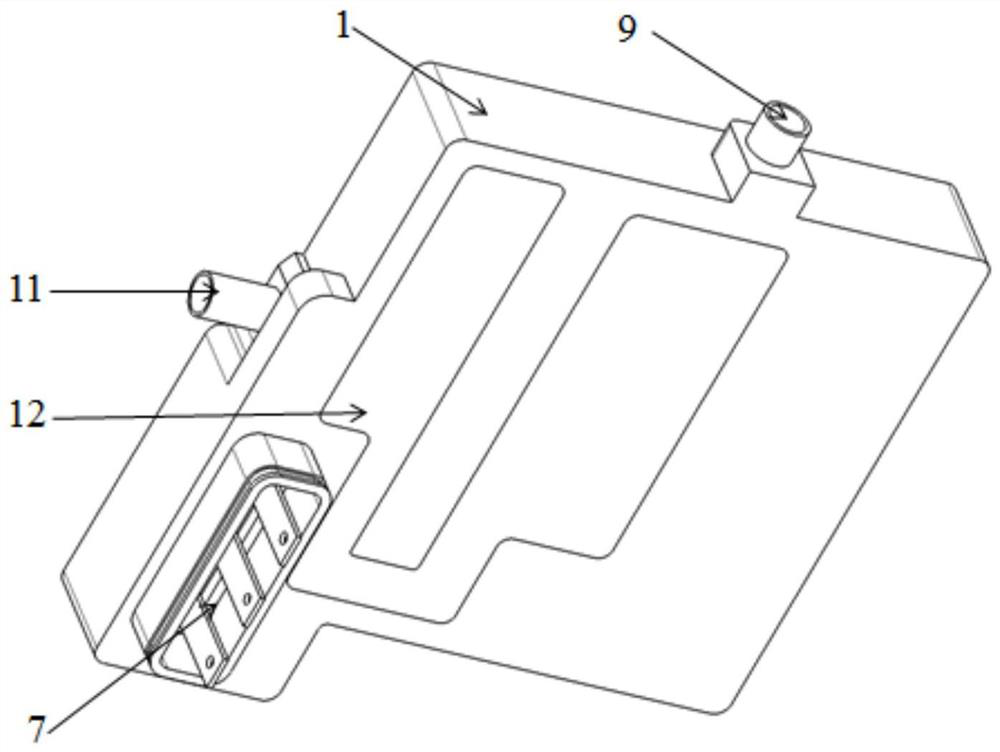

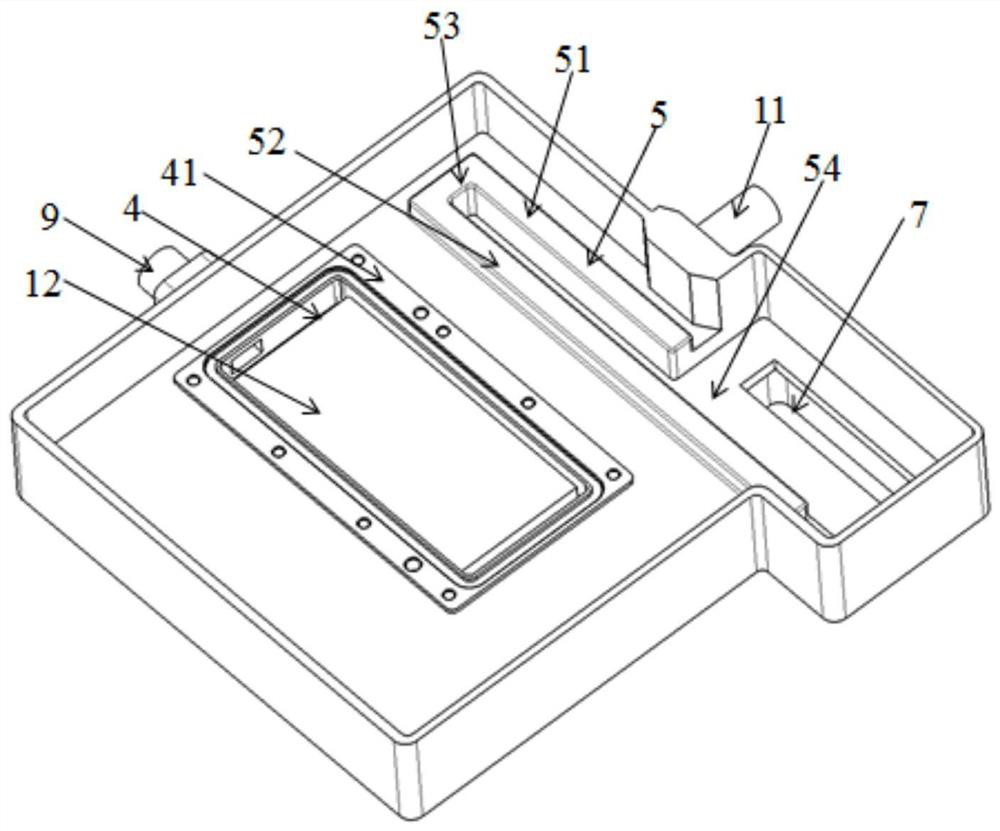

[0038] Such as Figure 1-10 As shown, a motor controller with a laminated busbar heat dissipation structure provided by the present invention includes a housing 1, an IGBT module 2 installed in the housing 1, and a laminated busbar 3. The housing 1 is provided with a top The opening cooling water tank 4, the IGBT module 2 is sealed and connected around the notch of the cooling water tank 4, and the casing 1 also protrudes to form a U-shaped installation part 5 with a horizontal projection, and an insulating heat conduction pad 6 is provided between the two arms of the installation part 5 And the laminated busbar 3 is arranged in the insulating heat conduction pad 6 for heat transfer, and the housing 1 is provided with an interface 7 corresponding to the output end of the laminated busbar 3 . The interior of the installation part 5 is provided with a cooling water channel 8 along the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com