Single-screw pneumatic ditching fertilizer applicator

A pneumatic, single-spiral technology, applied in fertilization devices, excavation/covering of trenches, planting methods, etc., can solve the problems of easy damage to the machine, difficulty in adapting to the working environment of tea gardens, strong fertilization of fruit trees, etc., to improve practicability. and applicability, good practicability and applicability, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

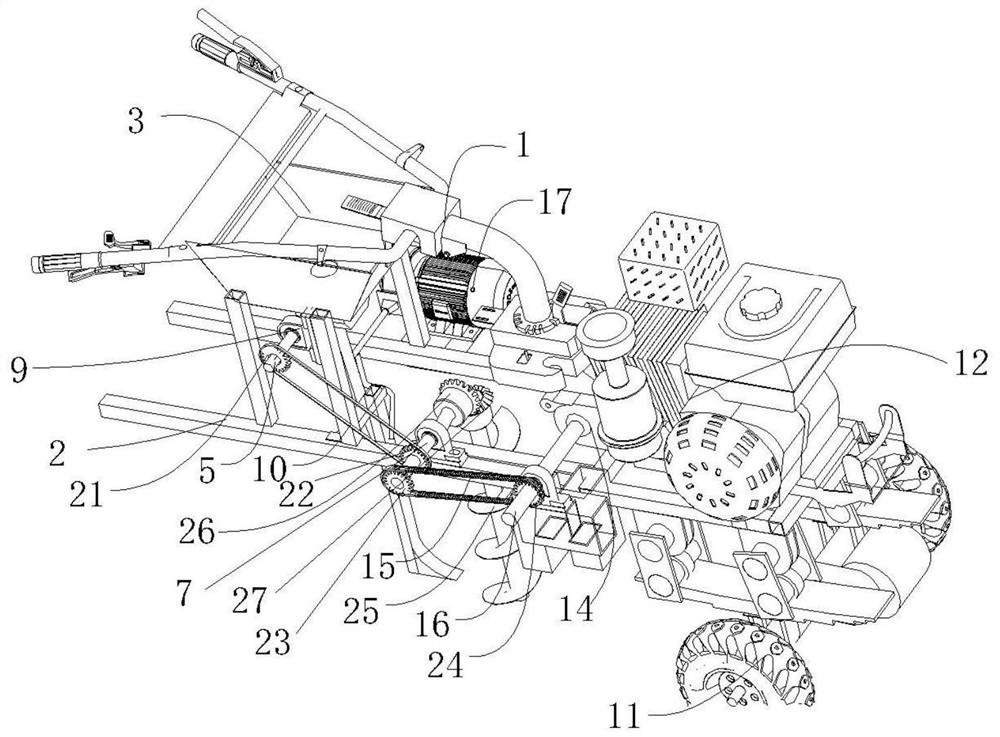

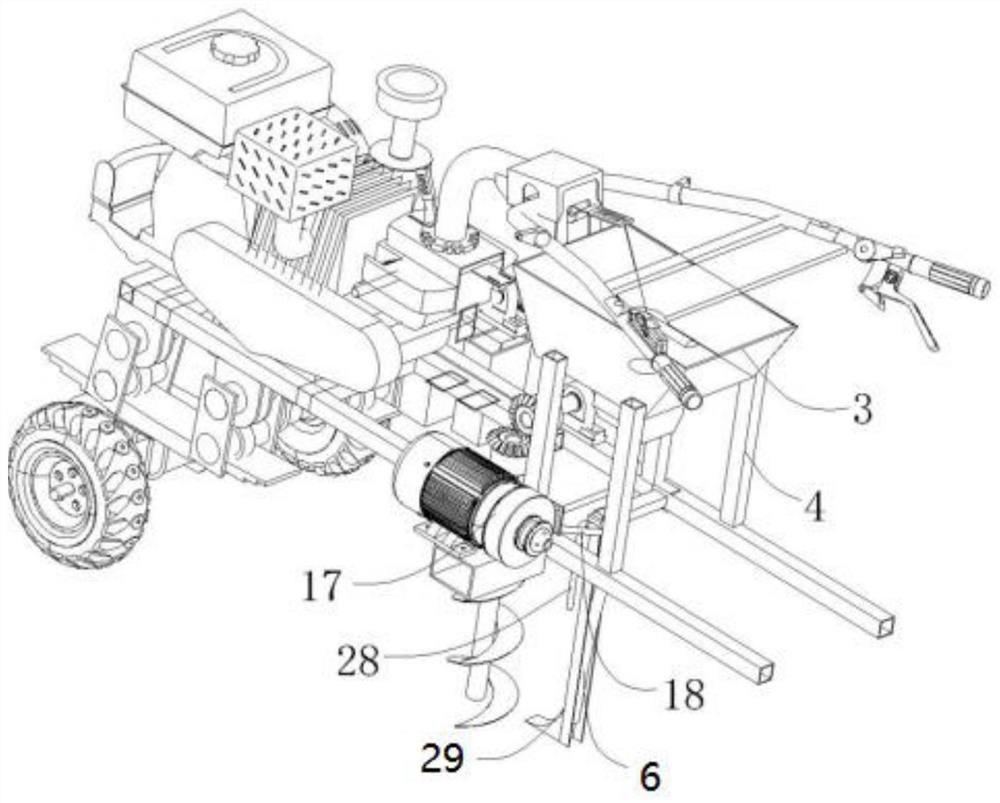

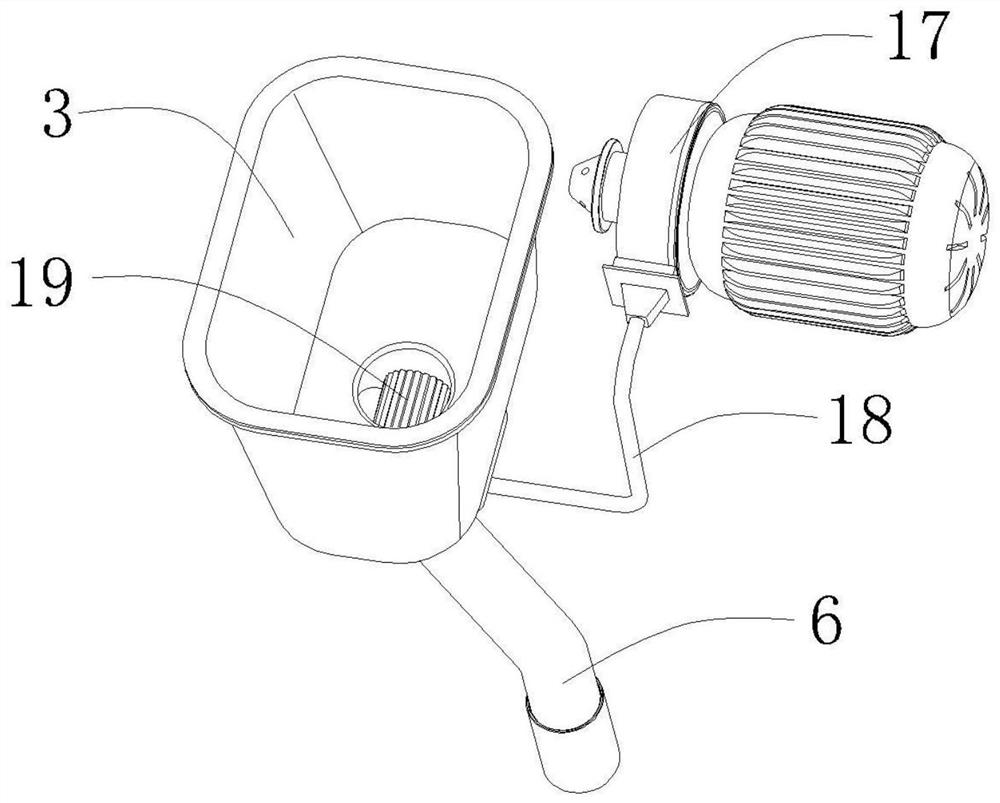

[0022] refer to figure 1 , a single-screw pneumatic ditch fertilizer applicator figure 1 , including frame 2, handrail 1, first rotating shaft 16, second rotating shaft 7, third rotating shaft 5, power unit, ditching device, air pump 17, walking device 11, air pipe and fertilization unit, right front to rear on the frame 2 A power device, a ditching mechanism and a fertilizing device are fixedly arranged in sequence. The traveling device is arranged under the frame, and the traveling device 11 includes a motor and a traveling wheel. The motor is fixedly connected to the frame 2. The left and right ends of the motor are connected to one end of the rotating shaft in rotation, and the other end of the rotating shaft passes through the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com