A controllable degradable embolic microsphere responsive to magnetic response hyperthermia and its preparation method and application

A technology of embolization microspheres and magnetic response, which is applied in the field of biological and medical nanomaterials, can solve the problems of large individual differences and uncontrollable degradation cycle of degradable embolization microspheres, so as to reduce damage, increase saturation magnetization and resist Oxidation ability, the effect of accelerating the degradation of microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

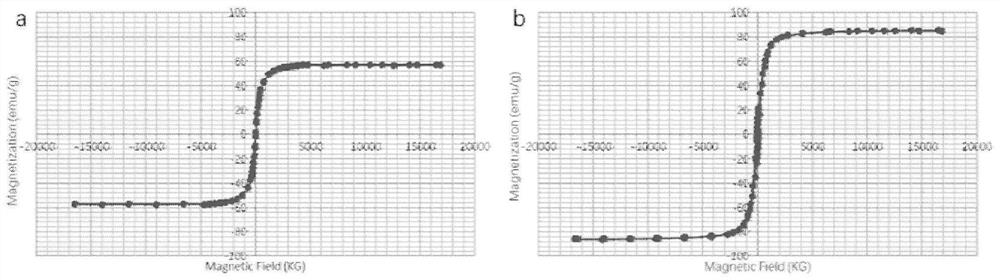

[0032] Determination of hysteresis loop of magnetic iron oxide with particle size of 10, 50, 100, 200, 300, 400, 500, 600 nm

[0033] Weigh 8 mg of magnetic iron oxide particles of the above specifications respectively, and measure the hysteresis loop of the sample with a vibrating sample magnetometer (VSM). The results are shown in Table 1:

[0034] Table 1

[0035]

[0036]

[0037] According to Table 1, it can be seen that the saturation magnetization of magnetic iron oxide is related to the particle size. The larger the particle size, the stronger the saturation magnetization. The particle size is in the range of 200-500nm, and the saturation magnetization of magnetic iron oxide is greater than 80emu / g. Among them, the hysteresis loops of magnetic iron oxide with particle size of 10nm and 300nm are as follows figure 1 As shown in the figure, the saturation magnetization of the magnetic iron oxide with a particle size of 10 nm is 57 emu / g, and the saturation magnetiz...

Embodiment 2

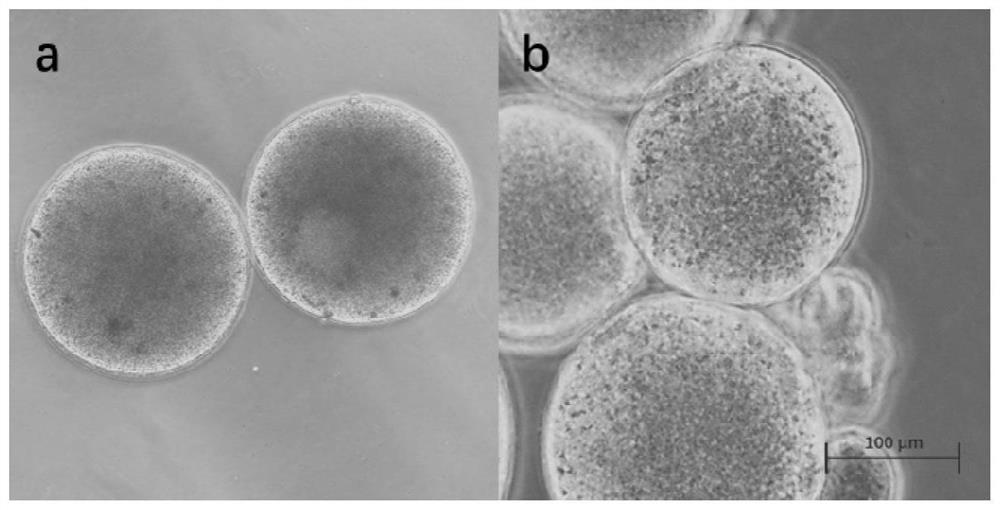

[0039] Preparation of 10nm-scale magnetic iron oxide carrageenan-gelatin plugging microspheres by emulsification and cross-linking method

[0040] Weigh 0.6 g of gelatin, 0.6 g of carrageenan and 50 mg of 10-nm-grade magnetic iron oxide powder, slowly sprinkle the powder in 10 mL of pure water, and swell at 55° C. for 20 min to prepare an aqueous phase. Measure 50 mL of liquid paraffin, add 0.4 g of Span80 dropwise, and preheat at 55°C to prepare an oil phase. The oil phase was slowly poured into the water phase, and stirred at 55° C. and 800 rpm for 30 min to form colostrum. Stir and cool for 30 min, drop 1.5 mL of 25% glutaraldehyde solution, and continue to stir and crosslink for 1 h. Finally, 30 mL of isopropanol was added to stir and dehydrate for 15 minutes, then washed with isopropanol, water and anhydrous ethanol in stages, filtered with suction, dried in an oven at 60°C for 30 minutes, ground and sorted to obtain microspheres. The dried microspheres are brownish yel...

Embodiment 3

[0042] Preparation of 50nm-sized Magnetic Iron Oxide Carrageenan-Gelatin Embolization Microspheres by Emulsification and Cross-linking

[0043]Weigh 0.6g of gelatin, 0.6g of carrageenan and 50mg of 50nm magnetic iron oxide powder, slowly sprinkle the powder in 10mL of pure water, and swell at 55°C for 20min to make the water phase. Measure 50mL of liquid paraffin, add 0.4g of Span80 dropwise, and preheat at 55°C to make an oil phase. Slowly inject the oil phase into the water phase, stir at 55°C and 800rpm for 30min to form colostrum. Stir and cool for 30 min, add 1.5 mL of 25% glutaraldehyde solution dropwise, and continue stirring for 1 h to cross-link. Finally, 30 mL of isopropanol was added, stirred and dehydrated for 15 minutes, then washed with isopropanol, water and absolute ethanol several times, filtered with suction, dried in an oven at 60°C for 30 minutes, ground and sorted to obtain microspheres. Dried microspheres are brownish-yellow with uniform particle size. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com