Lakebed pollutant continuous treatment device

A treatment device and pollutant technology, applied in the field of pollutant treatment, can solve the problems affecting the toughness of the blade, continuous treatment of unfavorable pollutants, clogging and other problems, and achieve the effect of rapid cutting and crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

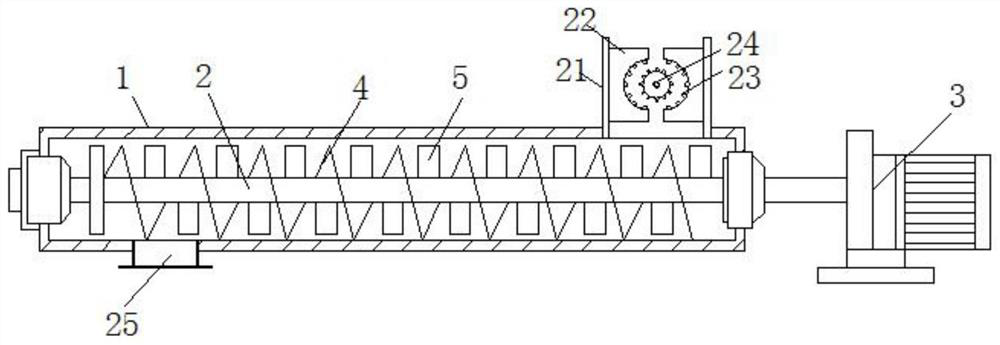

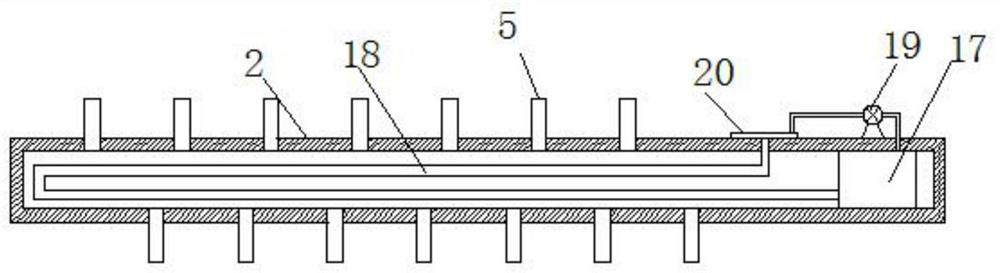

[0030] Such as Figure 1-4 As shown, the lake bottom pollutant continuous treatment device includes a shell 1,

[0031] A helical shaft 2 is provided for rotation in the housing 1, and one end of the helical shaft 2 extends out of the housing 1 and is provided with a servo motor 3;

[0032] A plurality of helical blades 4 are evenly distributed along the horizontal axis on the helical shaft 2, and a crushing shaft 5 is arranged between every two helical blades 4, and the pulverizing shaft 5 is arranged on the helical shaft 2;

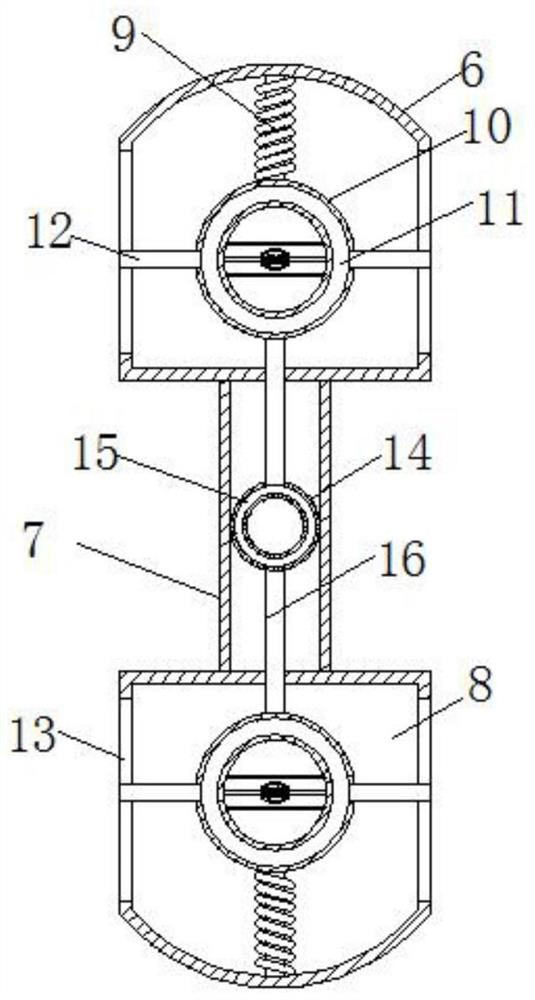

[0033] The crushing shaft 5 includes two crushing blades 6, connected by a connecting plate 7 between the two crushing blades 6, an installation cavity 8 is arranged in the crushing blade 6, an annular plate-10 is arranged in the installation cavity 8, and an annular plate-10 is arranged Elastic chamber 11 is arranged, and two blades 12 are symmetrically arranged on the elastic chamber 11 by sliding through the moving mechanism, and two strip-shaped sl...

Embodiment 2

[0038] Such as Figure 1-4 Shown, moving mechanism comprises strip plate 26, and strip plate 26 is arranged on ring plate one 10 centers, and in strip plate 26, symmetrical sliding is provided with moving rod 27, and one end of moving rod 27 stretches in ring plate one 10 and Connected with the elastic chamber one 11, the other end of the moving rod 27 is provided with a fixed plate 28, a first spring 29 is connected between the two fixed plates 28, and the top and bottom of the two fixed plates 28 are hinged with a diagonal bar 30 , the other ends of the two slanting bars 30 are jointly hinged with a horizontal plate 31, the blade 12 is fixedly mounted on the horizontal plate 31, and the blade 12 and the strip plate 26 slide longitudinally, when the elastic cavity 11 is heated and expanded, it drives The moving rod 27 moves, thereby driving the two fixed plates 28 to compress the first spring 29, thereby driving the hinged inclined rod 7 to move, thereby realizing the movemen...

Embodiment 3

[0040] Such as Figure 1-4 As shown, the lake bottom pollutant continuous treatment device includes a shell 1,

[0041] A helical shaft 2 is provided for rotation in the housing 1, and one end of the helical shaft 2 extends out of the housing 1 and is provided with a servo motor 3;

[0042] A plurality of helical blades 4 are evenly distributed along the horizontal axis on the helical shaft 2, and a crushing shaft 5 is arranged between every two helical blades 4, and the pulverizing shaft 5 is arranged on the helical shaft 2;

[0043] The crushing shaft 5 includes two crushing blades 6, connected by a connecting plate 7 between the two crushing blades 6, an installation cavity 8 is arranged in the crushing blade 6, an annular plate-10 is arranged in the installation cavity 8, and an annular plate-10 is arranged Elastic chamber one 11 is arranged, two blades 12 are symmetrically arranged on the elastic chamber one 11, and two strip-shaped slide holes 13 are symmetrically arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com