Composite vibrating diaphragm of sound production device and sound production device

A technology of sound-emitting device and rubber layer, which is applied in the direction of diaphragm structure, synthetic resin layered products, chemical instruments and methods, etc., to achieve the effect of satisfying the degree of tolerance and meeting the needs of experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In a second aspect, a method for preparing a composite diaphragm of a sounding device is provided, comprising the following steps:

[0057] A rubber layer is provided, wherein, the rubber layer is prepared by: forming a film body through a film-forming process, and drying the film body at a low temperature to form an uncrosslinked rubber layer or a semi-crosslinked rubber layer;

[0058] Laminating the rubber layer and the thermoplastic elastomer layer to form a composite film;

[0059] The composite film is molded to form a vibrating film.

[0060] In the embodiment of the present application, the drying process of the rubber layer adopts a low-temperature drying method so that it does not produce chemical crosslinking or semi-chemical crosslinking; then the rubber layer and the thermoplastic elastomer layer are bonded to form a composite film, and the composite film is The diaphragm is chemically cross-linked and set during molding. The composite diaphragm prepared ...

Embodiment 1

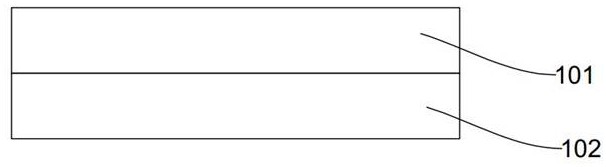

[0067] Such as figure 1 As shown, a composite diaphragm of a sounding device is composed of a layer of thermoplastic elastomer layer 101 and a layer of rubber layer 102. The rubber layer 102 is made of ethylene-vinyl acetate rubber; the rubber layer 102 The thickness is 30 μm.

[0068] The ethylene-vinyl acetate rubber is formed by copolymerization of ethylene and vinyl acetate, and the content of the vinyl acetate is 40% of the total amount of the ethylene-vinyl acetate rubber.

[0069] The hardness of the rubber layer 102 is 30A; the dissipation factor of the rubber layer 102 is greater than 0.05 at room temperature.

[0070] The thickness of the thermoplastic elastomer layer 101 is 15 μm; the material of the thermoplastic elastomer layer 101 is selected from TPEE (polyester elastomer).

Embodiment 2

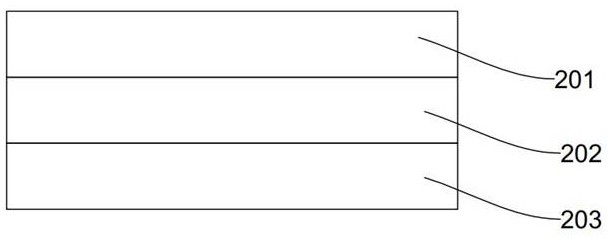

[0072] Such as figure 2 As shown, a composite diaphragm of a sounding device includes a first thermoplastic elastomer layer 201, a rubber layer 202 and a second thermoplastic elastomer layer 203 laminated in sequence, and the rubber layer 202 is made of ethylene-vinyl acetate rubber ; The thickness of the rubber layer 202 is 15 μm.

[0073] The ethylene-vinyl acetate rubber is formed by copolymerization of ethylene and vinyl acetate, and the content of the vinyl acetate is 60% of the total amount of the ethylene-vinyl acetate rubber.

[0074] The hardness of the rubber layer 202 is 65A; the dissipation factor of the rubber layer 202 is greater than 0.1 at room temperature.

[0075] The thickness of the first thermoplastic elastomer layer 201 is 15 μm; the material of the first thermoplastic elastomer layer 201 is selected from TPEE (polyester elastomer).

[0076] The thickness of the second thermoplastic elastomer layer 203 is 15 μm; the material of the second thermoplastic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com