Composite vibrating diaphragm of sound production device and preparation method thereof and sound production device

A technology of a sounding device and a composite membrane, which is applied in the directions of chemical instruments and methods, diaphragm structures, synthetic resin layered products, etc. The lack of overall resilience and the decline of product reliability can achieve the effect of improving peeling force, excellent resilience and reducing film folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

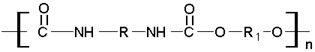

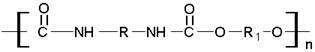

[0044] As described in the background art, the composite diaphragm in the prior art includes a thermoplastic elastomer layer and an adhesive film layer. In this composite diaphragm, the bonding force between the thermoplastic elastomer layer and the adhesive film layer is not strong enough. As a result, the reliability of the product is reduced, and there will be problems of delamination or even membrane rupture after long-term vibration; at the same time, the overall resilience of the composite diaphragm is lacking, and there are risks of diaphragm membrane folding and collapse after large amplitude or strict air tightness tests. In order to solve the above technical problems, the present invention provides a composite diaphragm of a sounding device, a preparation method thereof, and a sounding device.

[0045] In a first aspect, a method for preparing a composite diaphragm of a sounding device is provided, the composite diaphragm includes at least one layer of thermoplastic e...

Embodiment 1

[0081] A method for preparing a composite diaphragm of a sounding device, wherein the composite diaphragm is composed of a layer of thermoplastic elastomer and a layer of thermosetting polyurethane rubber;

[0082] The preparation method of the composite diaphragm comprises the following steps:

[0083] A rubber layer is provided, wherein, the preparation method of the rubber layer is: using polyurethane rubber to make a film body through a calendering process, and the film body is an uncrosslinked polyurethane rubber layer;

[0084] Laminating the rubber layer and the thermoplastic elastomer layer to form a composite film;

[0085]The composite film is subjected to molding treatment to form a vibrating membrane, and in the molding treatment, the non-crosslinked polyurethane rubber layer or the semi-crosslinked polyurethane rubber layer is subjected to a crosslinking reaction to form a thermosetting polyurethane rubber layer.

[0086] The forming process is air pressure formi...

Embodiment 2

[0090] A composite vibrating membrane of a sounding device, the composite vibrating membrane comprises two thermoplastic elastomer layers and one thermosetting polyurethane rubber layer, and the two thermoplastic elastomer layers are respectively arranged on the two surfaces of the thermosetting polyurethane rubber layer.

[0091] The preparation method of the composite diaphragm comprises the following steps:

[0092] A rubber layer is provided, wherein, the preparation method of the rubber layer is: adopt polyurethane rubber to form a film body through a coating process, and dry the film body at a low temperature to form an uncrosslinked polyurethane rubber layer or a semi-crosslinked polyurethane rubber layer layer;

[0093] Laminating the rubber layer and the thermoplastic elastomer layer to form a composite film;

[0094] The composite film is subjected to molding treatment to form a vibrating membrane, and in the molding treatment, the non-crosslinked polyurethane rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com