Inking method for cover plate glass

A technology for cover glass and steel plate, which is applied in the production of special varieties of printed matter, such as printing, post-printing, and printing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] When the cover glass is 3D cover glass, the method of inking is as follows:

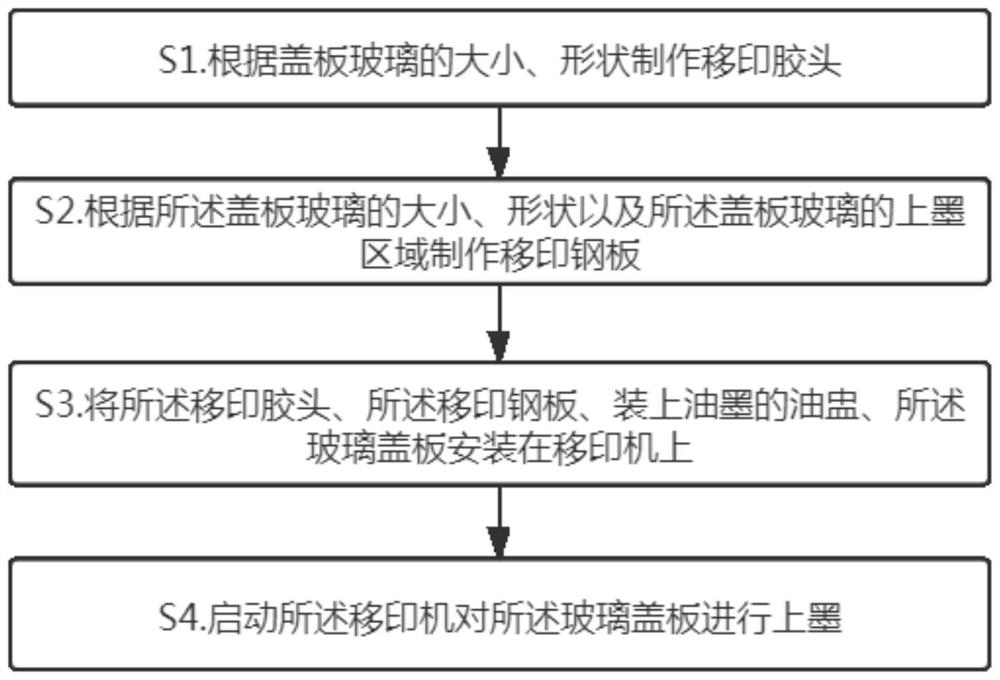

[0091] The cover glass needs to be cleaned before inking on the cover glass, and the cover glass is transferred to the inserting ultrasonic machine for cleaning. The parameters are set at 40~110℃ / 40~60kHz / 60~120s. like figure 1 As shown, it is a flow chart of the steps of a method for inking a cover glass provided by an embodiment of the present invention, including steps:

[0092] S1. Make pad printing pads according to the size and shape of the cover glass;

[0093] S2. making a pad printing steel plate according to the size and shape of the cover glass and the inked area of the cover glass;

[0094] S3. Install the pad printing rubber head, the pad printing steel plate, the oil cup filled with ink, and the glass cover plate on the pad printing machine;

[0095] S4. Start the pad printer to add ink to the glass cover.

[0096] Wherein, the specific steps of making the pad printing rubb...

Embodiment 2

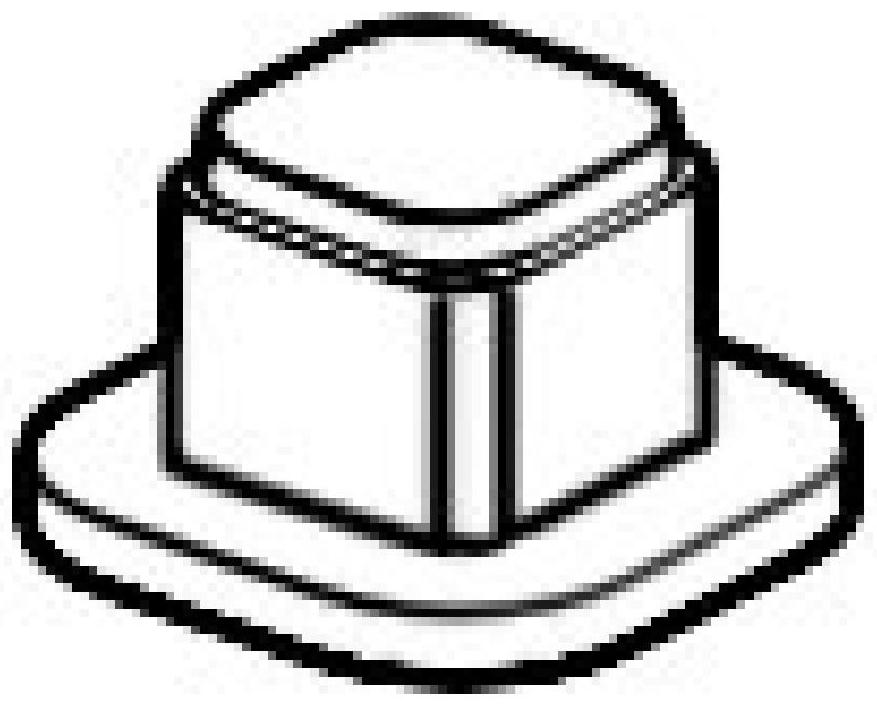

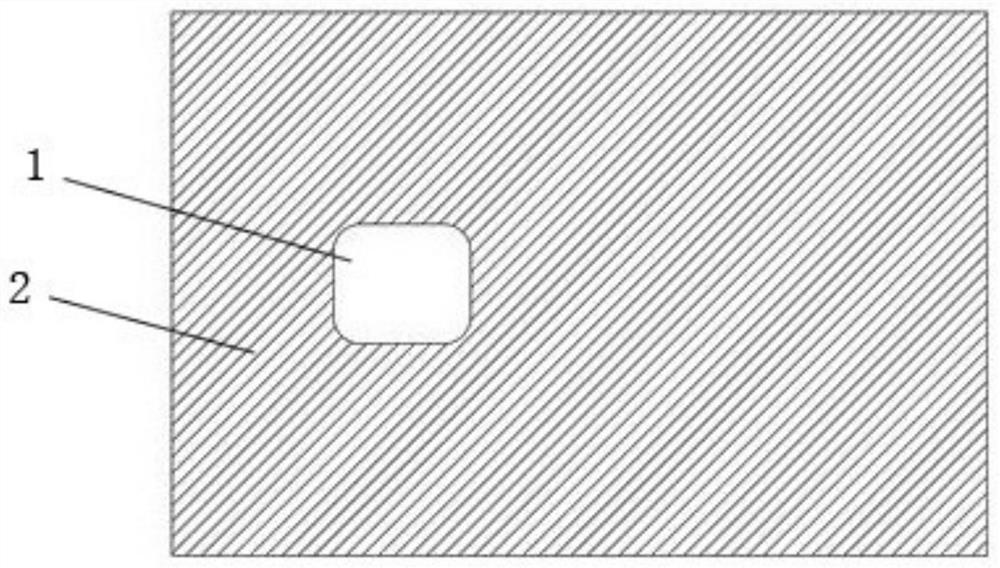

[0113] When the cover glass is the glass middle frame, the steps before pad printing and ink twice (that is, the steps before step S45) are the same as in Example 1, and the structure of the pad printing rubber head for pad printing the glass middle frame is as follows Figure 11 as shown, Figure 12 It is a schematic diagram of the etching area of the steel plate, where position 1 is the etching area, and position 2 is the non-etching area. like Figure 13 Shown, inking step S4 comprises:

[0114] S41. Attach the pad printing steel plate under the oil cup; move the oil cup to the etching area of the pad printing steel plate; open the oil cup to allow ink to flow into the etching area of the pad printing steel plate; close said oil cup;

[0115] S42. The oil cup moves to the non-etching area of the pad printing steel plate; the pad printing rubber head is pressed down at a first pressing speed, and when the pad printing rubber head is at a first distance from the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com