Rubber material for rubber water seal and preparation forming method and equipment thereof

A rubber water seal and rubber material technology, which is applied in the field of hydraulic metal structure rubber water seal production and on-site installation, can solve the problem that the actual strength of hot vulcanized bonding joints is difficult to achieve the desired effect, so as to improve the vulcanized bonding strength and increase the Crosslinking density, the effect of increasing the quality of the vulcanized bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A high-water-head rubber water-sealing compound, the active ingredients of which are calculated in parts by weight: 100 parts of No. 3 smoked sheet rubber, 14.91 parts of quick-pressed carbon black, 34.73 parts of high-wear-resistant carbon black, and 14.91 parts of gas-mixed carbon black , 4.47 parts of zinc oxide, 2.09 parts of stearic acid, 2.00 parts of paraffin, 1.09 parts of anti-aging agent RD, 2.98 parts of vaseline, 0.73 parts of accelerator NOBS, 0.11 parts of accelerator D, 1.00 parts of anti-aging agent 4010NA, anti-scorch Agent CTP 0.31 parts, sulfur S-80 2.49 parts, EPDM rubber 20.91 parts.

Embodiment 2

[0032]A high-water-head rubber water-sealing rubber compound, the active ingredients of which are calculated in parts by weight: 100 parts of No. 3 smoke sheet rubber, 14.6 parts of fast extruded carbon black, 34.5 parts of high wear-resistant carbon black, and 14.6 parts of gas-mixed carbon black , 4.1 parts of zinc oxide, 2.0 parts of stearic acid, 1.8 parts of paraffin, 1.0 parts of anti-aging agent RD, 2.8 parts of Vaseline, 0.6 parts of accelerator NOBS, 0.05 parts of accelerator D, 0.9 parts of anti-aging agent 4010NA, 0.2 parts of anti-scorch agent CTP , Sulfur S-80 2.3 parts, EPDM rubber 19.5 parts.

Embodiment 3

[0034] A high-water-head rubber water-sealing rubber compound, the active ingredients of which are calculated in parts by weight: 100 parts of No. 3 smoke sheet rubber, 15.0 parts of quick-extruded carbon black, 34.8 parts of high-wear-resistant carbon black, and 15.0 parts of gas-mixed carbon black , 4.5 parts of zinc oxide, 2.2 parts of stearic acid, 2.1 parts of paraffin, 1.1 parts of anti-aging agent RD, 3.1 parts of Vaseline, 0.8 parts of accelerator NOBS, 0.15 parts of accelerator D, 1.3 parts of anti-aging agent 4010NA, 0.4 parts of anti-scorch agent CTP , Sulfur S-80 2.7 parts, EPDM rubber 22.0 parts.

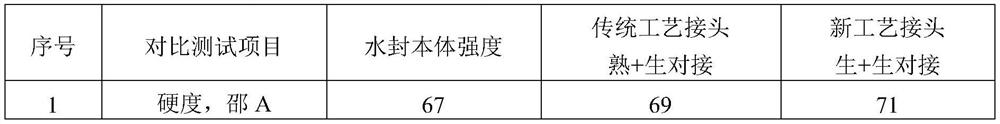

[0035] The rubber water seals produced by vulcanizing the rubber materials in the above Examples 1-3 and Comparative Examples were tested. The hardness of the water seals obtained by vulcanizing the high-head rubber water seal materials in Comparative Example 1, Shore A: 68 degrees, tensile Strength 22.6Mpa, elongation at break 548%. The rubber water seal hardness (Sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com