RH refining method for removing inclusions in molten steel

A technology of inclusions and molten steel, applied in the field of iron and steel metallurgical refining, can solve problems such as hidden safety hazards, increase enterprise management costs, and unconsidered relationships, and achieve the effect of improving cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

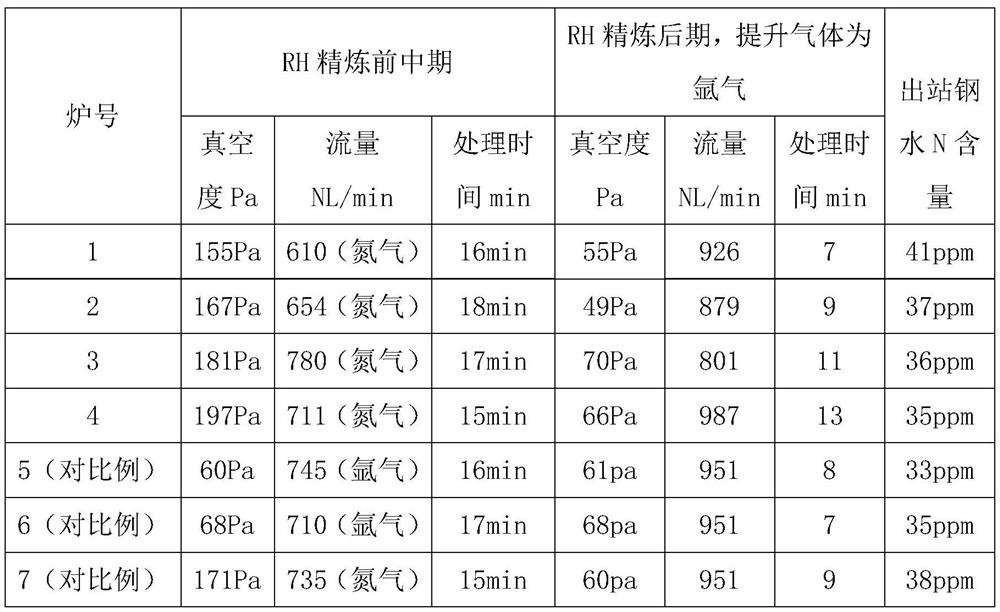

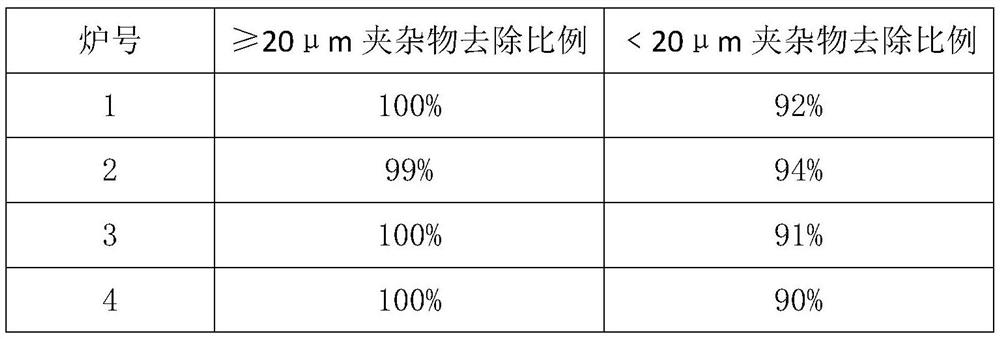

[0026] A RH refining method for removing inclusions in molten steel, comprising the following steps:

[0027] 1) It is required that [O] in RH incoming molten steel (both mass fractions) is less than 20ppm, [S] is less than 20ppm, and [Cr] is less than 5% (too high content is not conducive to denitrification); the ladle used for vacuum treatment needs to have a The bottom blowing element is located directly below the rising dipping pipe of RH; after RH enters the station (in the middle period before vacuum treatment), the bottom blowing of the ladle directly below the lifting dipping pipe is turned on, the flow rate is 0.30-1.75NL / (min.t), and vacuum treatment is started , the vacuum degree is kept at 150-200Pa, the lifting gas is nitrogen, the flow rate is 5.20-7.10NL / (min.t), and the processing time is 15-18min.

[0028] 2) After step 1), turn off the bottom blowing of the ladle and enter the later stage of RH vacuum treatment. The vacuum degree of the vacuum tank is less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com