Curtain wall board adopting basalt fiber fabric as facing layer and manufacturing method of curtain wall board

A technology of basalt fiber and veneer layer, which is applied in building structures, walls, building components, etc., to achieve the effect of moist texture, expanding application scope and elegant color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

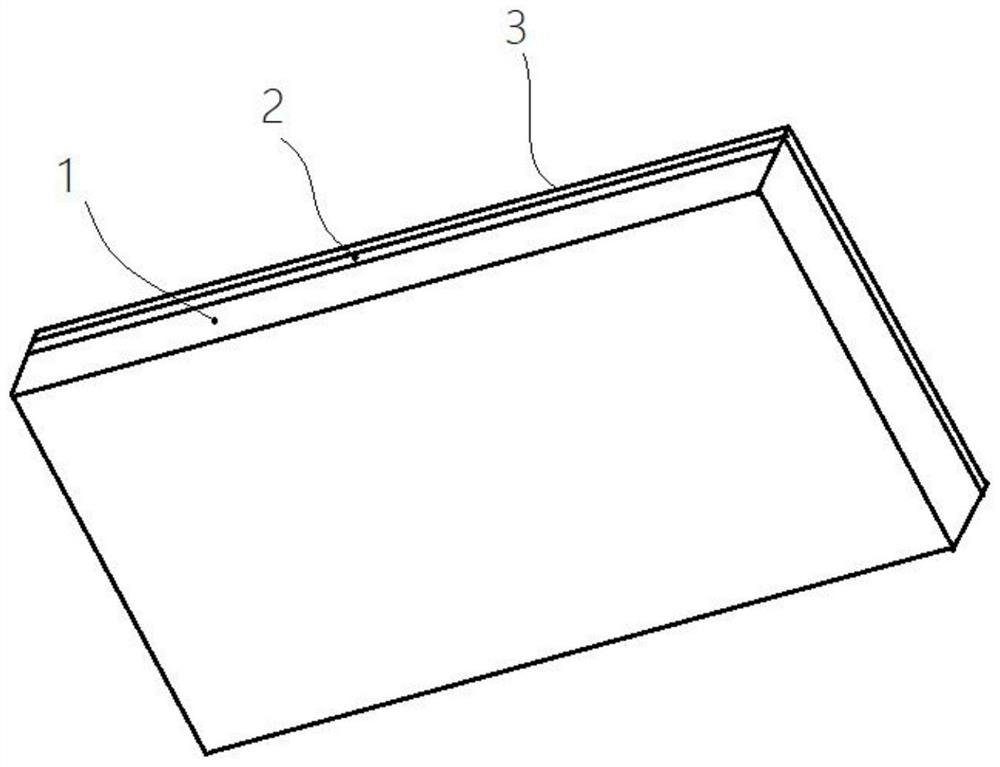

[0023] Such as figure 1 As shown, a curtain wall panel with basalt fiber fabric as the finishing layer includes a base layer of the panel 1, a basalt fiber fabric layer 2 bonded to the front of the base layer of the panel by an adhesive, and a transparent cover coated on the surface of the basalt fiber fabric layer Topping 3. The board base layer 1 is a commercially available composite aluminum-plastic board or glass fiber board. The adhesive is transparent vinyl resin or epoxy resin. The basalt fiber fabric layer 2 is commercially available basalt fiber fine gauze or basalt fiber roving. The coating of the transparent finish layer 3 adopts fluorocarbon paint, epoxy resin or acrylic resin.

[0024] The manufacturing method of the curtain wall panel with basalt fiber fabric as the facing layer according to the present invention, its method step is as follows:

[0025] A. Fully infiltrate the basalt fiber fabric with the binder;

[0026] B. Apply adhesive on the base layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com