Dynamic load deep mining area coal pillar instability unloading-solidifying-yielding multilevel prevention method

A technology for coal pillars and mining areas, which is applied in the field of multi-level prevention and control of coal pillar instability in deep mining areas under dynamic load, which can solve the problems of inability to ensure safe and efficient production of coal mines, failure to prevent rock bursts, Roadway dynamic disasters and other issues to achieve the effect of avoiding dynamic disaster accidents, strengthening the anti-dynamic load performance, and improving the overall carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

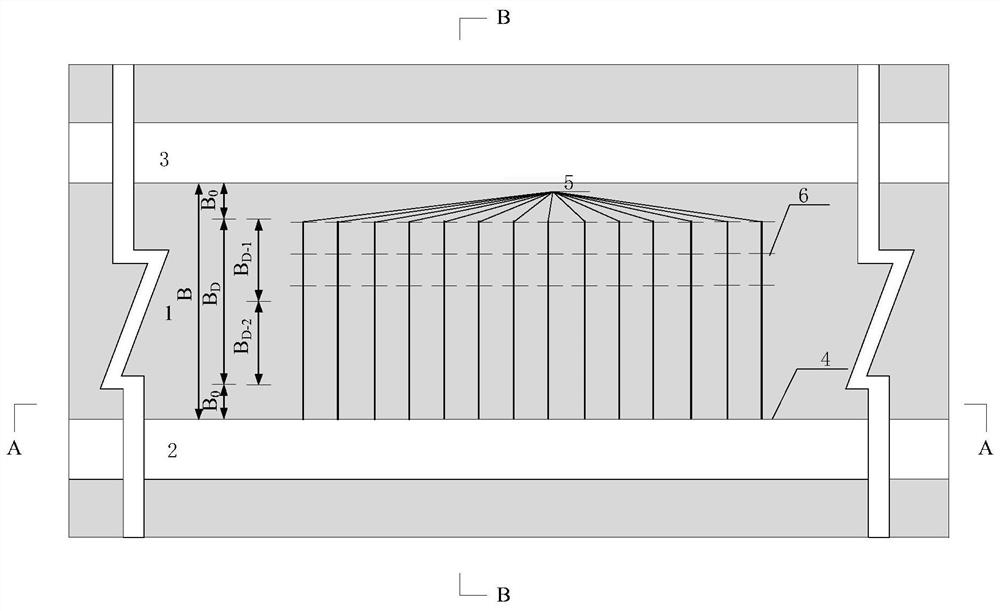

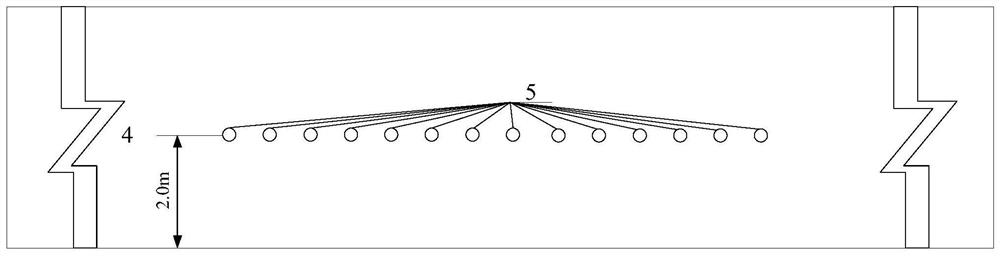

[0063] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0064] A "unloading-solid-yielding" multi-stage prevention and control method for coal pillar instability in a deep mining area under dynamic load, which is characterized in that it includes the following steps:

[0065] The first step, the determination of the target area for the implementation of "unloading-fixing-yielding" multi-level prevention and control of coal pillar instability in roadway protection

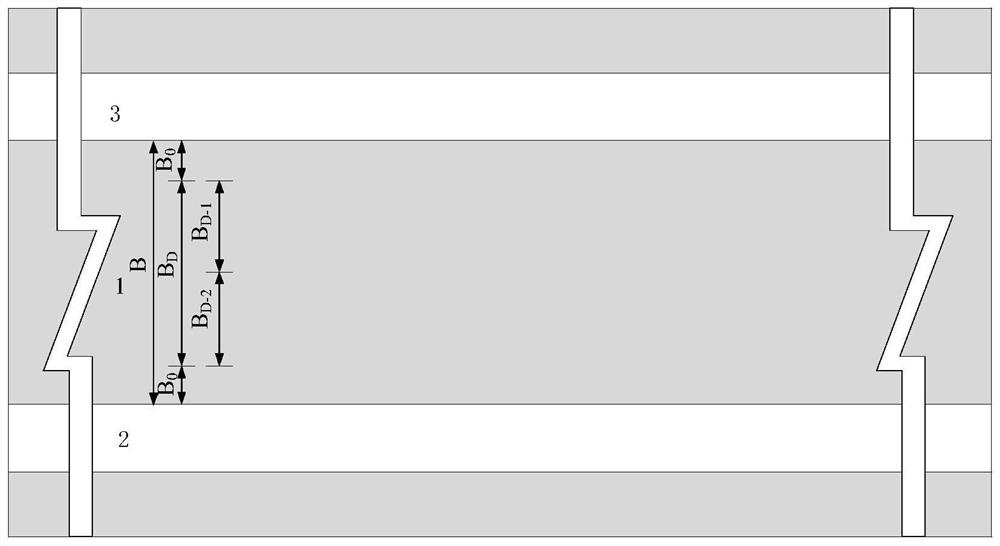

[0066] The coal pillar 1 of the roadway protection in the mining area is located between the track roadway 2 and the return air roadway 3. According to relevant research, the coal pillar 1 of the roadway protection roadway in the mining area forms a damage zone,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com