Exhaust gas recirculation system with asymmetric flow

A recirculation system, asymmetric technology, applied in the field of exhaust gas recirculation system, asymmetric flow exhaust gas recirculation system, can solve the requirements of high machining accuracy and consistency, difficulty in manufacturing asymmetric supercharger, increase engine fuel consumption, etc. problems, achieve low production and installation costs, reduce economic deterioration, and reduce NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: as figure 1 As shown, an exhaust gas recirculation system with asymmetric flow includes a symmetrical turbocharger, and the symmetrical turbocharger includes a turbine 11 and a compressor 12. The turbine 11 has two flow passages, and the two flows The channels are respectively a first flow channel 111 and a second flow channel 112, the second flow channel 112 of the turbine 11 is communicated with the first exhaust manifold 9, and the first flow channel 111 of the turbine 11 is communicated with the second exhaust manifold 10 , the other ends of the first exhaust manifold 9 and the second exhaust manifold 10 communicate with a certain number of exhaust manifolds corresponding to the engine 13, between the exhaust end and the intake end of the engine 13 An EGR line 14 is provided.

[0027] The number of exhaust manifolds of the engine 13 communicated with the first exhaust manifold 9 is greater than the quantity of exhaust manifolds of the engine 13 commun...

Embodiment 2

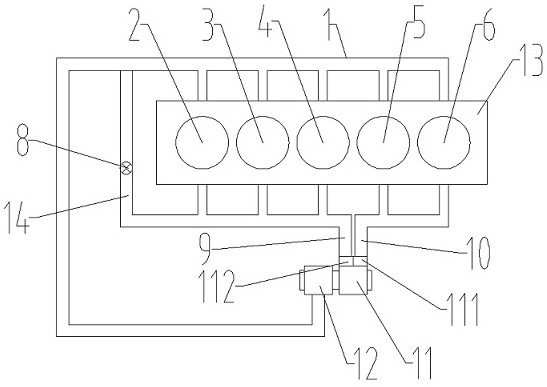

[0052] Embodiment 2: as figure 2 As shown, in the above-mentioned embodiment 1, the number of cylinders of the engine 13 can also be selected as five, and the five cylinders are respectively the first cylinder 2, the second cylinder 3, the third cylinder 4, and the fourth cylinder Body 5, the fifth cylinder body 6.

[0053] The other end of the first exhaust manifold 9 communicates with the exhaust manifolds of the first cylinder 2, the second cylinder 3, and the third cylinder 4 of the engine 13 respectively, and the second exhaust manifold 10 The other end communicates with the exhaust manifolds of the fourth cylinder 5 and the fifth cylinder 6 of the engine 13 respectively.

[0054] Such as figure 2 Shown, design like this, the waste gas discharged by the first cylinder body 2, the second cylinder body 3, and the third cylinder body 4 of engine 13 work respectively enters in the first exhaust manifold 9, and its fourth cylinder body 5, The exhaust gas discharged from t...

Embodiment 3

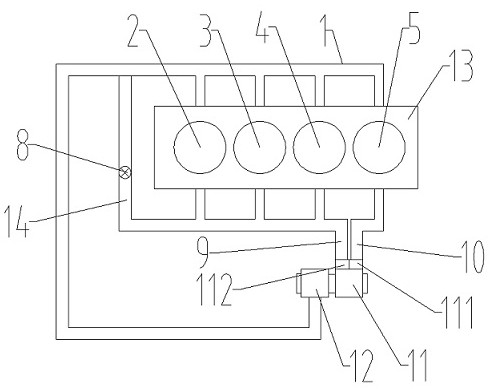

[0056] Embodiment 3: as image 3 As shown, in the above-mentioned embodiment 1, the number of cylinders of the engine 13 can also be selected from four, and the four cylinders are respectively the first cylinder 2, the second cylinder 3, the third cylinder 4, and the fourth cylinder Body 5.

[0057] The other end of the first exhaust manifold 9 communicates with the exhaust manifolds of the first cylinder 2, the second cylinder 3, and the third cylinder 4 of the engine 13 respectively, and the second exhaust manifold 10 The other end communicates with the exhaust manifold of the fourth cylinder 5 of the engine 13 .

[0058] Such as image 3 As shown, it is designed in this way, the exhaust gas discharged by the first cylinder body 2, the second cylinder body 3 and the third cylinder body 4 of the engine 13 works respectively enters in the first exhaust manifold 9, and its fourth cylinder body 5 discharges The exhaust gas enters the second exhaust manifold 10, at this time t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com