Central pipe provided with grid mesh and serving as draft pipe of vortex suppression device

A technology of central tube and draft tube, which is applied in the field of straight cone draft tube, can solve the problems of small cross-sectional area, difficult disassembly and replacement, and low fluid flow rate, so as to achieve stable water flow operation, reduce pressure pulsation, and increase continuous flow. The effect of time to do work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

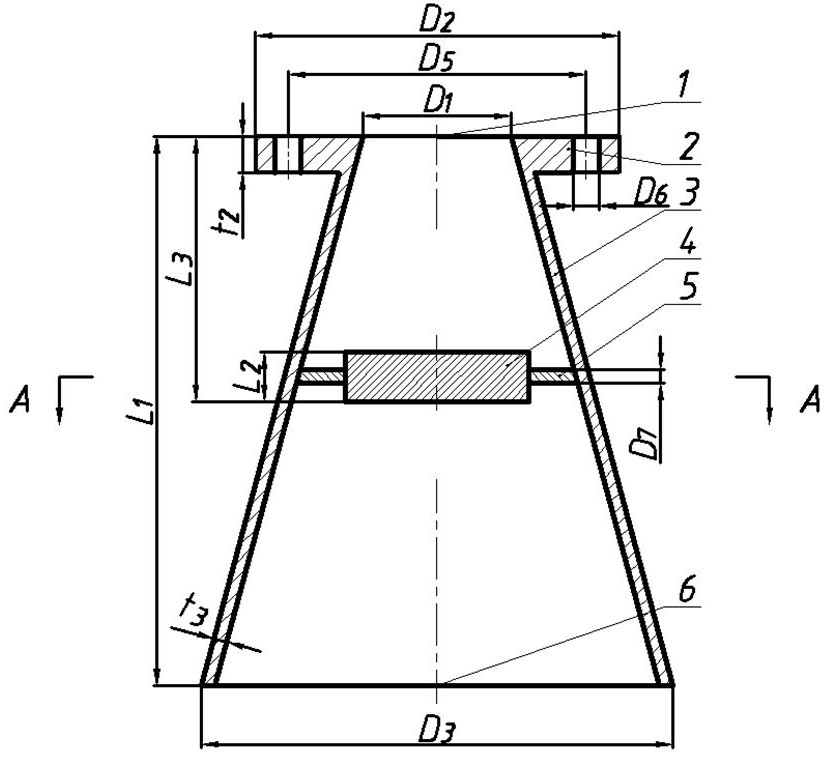

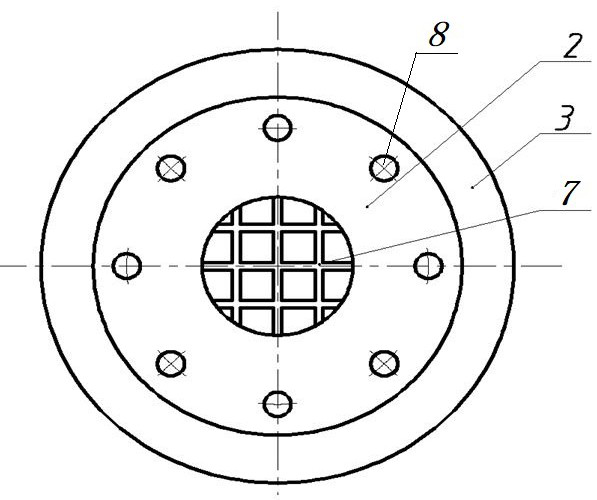

[0023] see figure 1 with figure 2 As shown, the draft tube of the present invention includes a straight cone 3, the axial section of the straight cone 3 is conical, its upper end is a small conical end, its lower end is a large conical end, and the small conical end is an open inlet 1. There is an open outlet 6 at the big end of the cone, so the straight cone 3 runs through from top to bottom. A flange structure 2 is arranged on the periphery of the upper inlet 1 of the straight cone 3, through which the flange structure 2 is fixedly connected with the outlet of the runner of the turbine and communicated with the outlet of the runner, so as to connect the draft tube to the turbine. Eight connecting holes 8 are evenly opened in the circumferential direction on the flange structure 2 , and the draft tube is fixed through these eight connecting holes 8 .

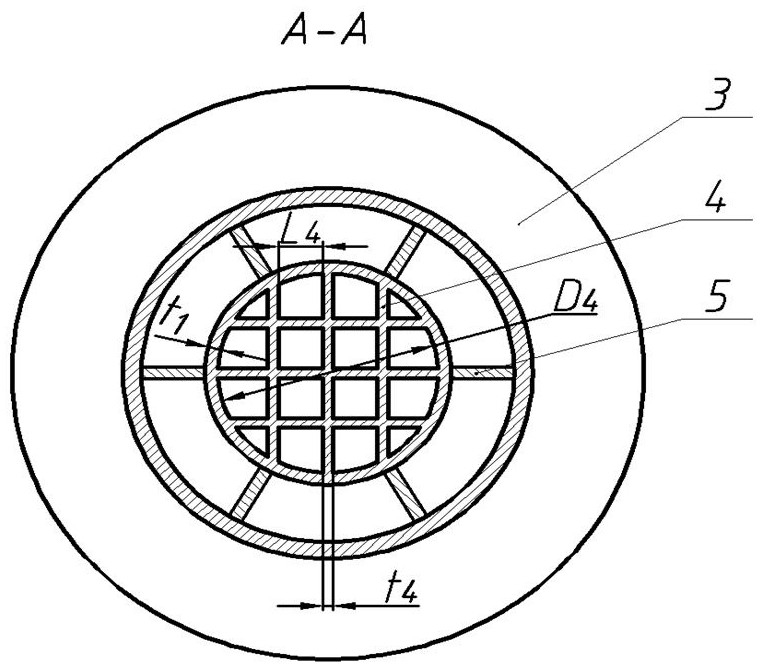

[0024] A central tube 4 is arranged inside the straight cone 3 , the profile of the central tube 4 is cylindrical, and its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com