Nondestructive monitoring system and method for diaphragm of diaphragm compressor

A diaphragm compressor and monitoring system technology, applied in the field of compressors, can solve problems such as the inability to trigger pressure alarms, and achieve the effect of non-destructive monitoring and diagnosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

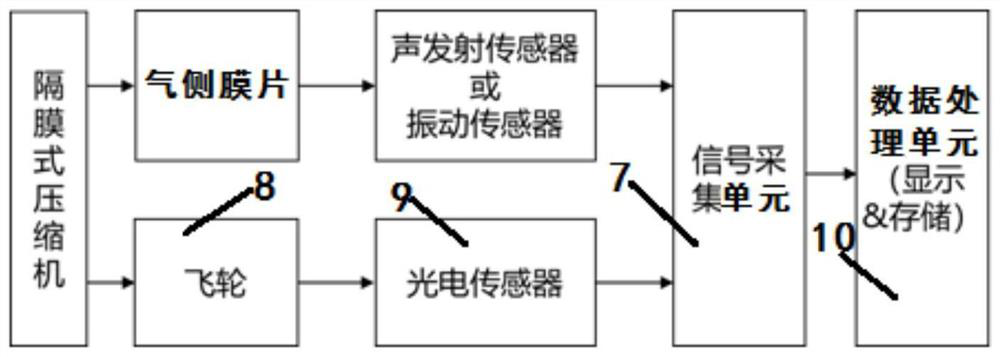

[0044] a. Build an acoustic emission or vibration signal measurement system

[0045] (1) Select a small acoustic emission sensor or vibration sensor with a suitable size and model according to the diaphragm material and diaphragm installation structure;

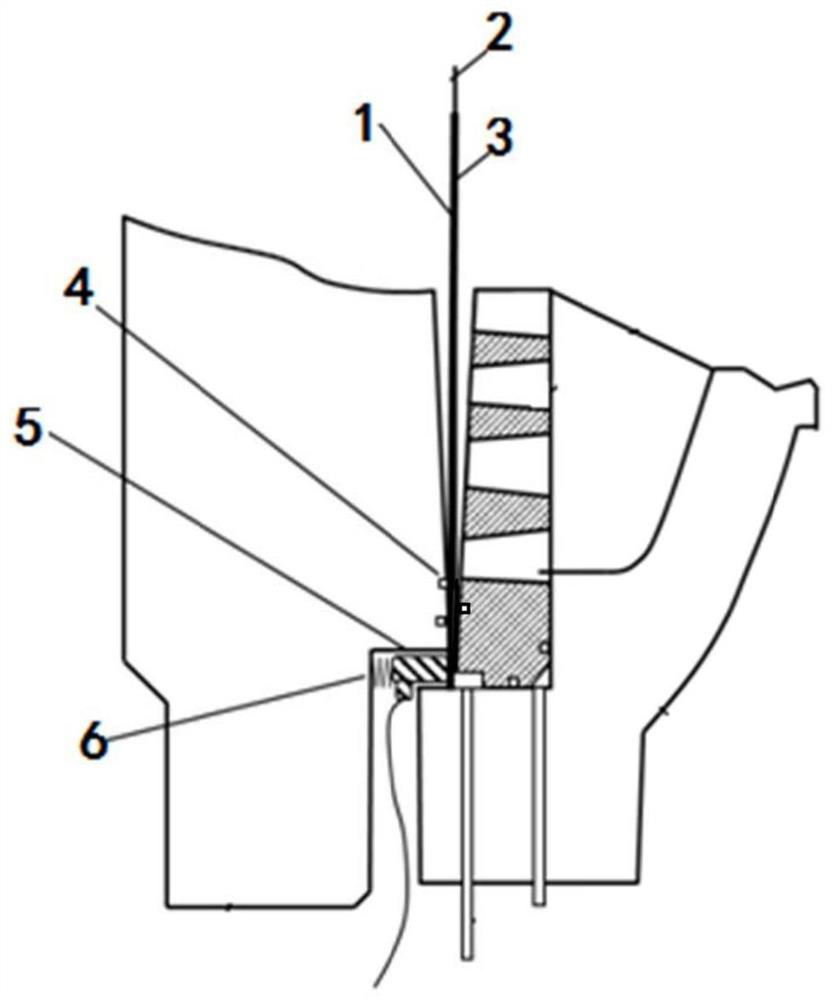

[0046](2) Cut out a sensor installation channel on the gas side cylinder head of the diaphragm compressor near the gas side diaphragm 1, and install a small acoustic emission sensor or vibration sensor. Because the cylinder and the oil cylinder in the diaphragm compressor are connected by bolts evenly distributed around the circumference, the outer edge of the diaphragm assembly is tightly pressed and supported by the cylinder and the oil cylinder, so the position where the sensor contacts the diaphragm is that the diaphragm is tightened by the oil / cylinder pressure The area of the branch, and the measurement is located outside the sealing O-ring, so this structure will not cause leakage and has little impact on the strengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com