A kind of hierarchical porous catalyst and its preparation method and application

A catalyst and a technology of hierarchical pores, which are applied in the field of hierarchical porous catalysts and their preparation, can solve the problems that the reaction process is difficult to effectively control, the reaction bed is easy to form hot spots, and the promotion of industrial applications is limited, so as to reduce the COX generation rate and avoid the The effect of deep oxidation and strong thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

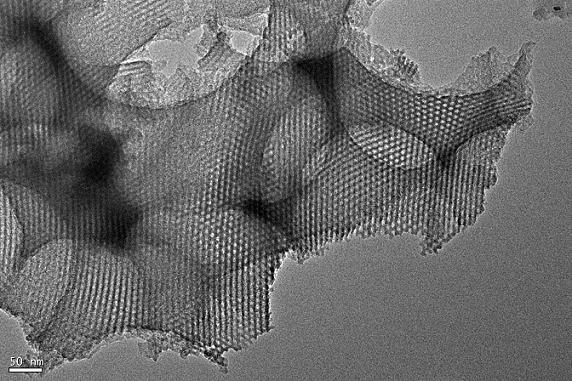

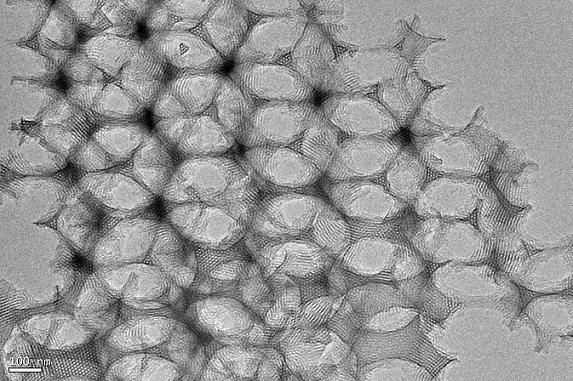

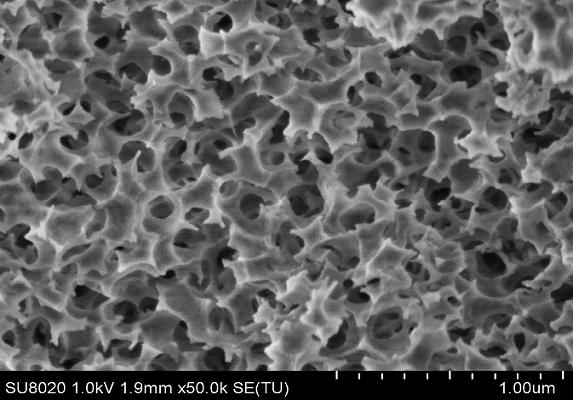

[0027] Example 1 A hierarchical porous catalyst, the catalyst consists of 23.12g of active components and 53.95g of SiO with three-dimensional ordered hierarchical pores 2 carrier; the active ingredient consists of 17.66g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.25g NH 4 VO 3 , 0.42gCu(CH 3 C00) 2 2H 2 O, 0.48g SbCl 3 , 0.30g H 3 AsO 4 , 1.09g H 3 PO 4 , 0.35g La(CH 3 COO) 3 1.5H 2 O, 0.45g Ce(NO 3 ) 3 ·6H 2 O and 2.12g CsOH·H 2 O composition.

[0028] Among them: SiO 2 The carrier refers to the synthesis of SiO by the method of volatile self-assembly using silicon source, macroporous template agent and mesoporous template agent. 2 Precursor, the precursor is dried at 100-120°C for 12-24h, and then calcined at no lower than 600°C for 4-8h to obtain SiO with a three-dimensional ordered macropore-mesoporous structure 2 . The specific method is as follows:

[0029]①Dissolve 50g of methyl methacrylate (MMA) in 500g of water to obtain an aqueous solution of methyl met...

Embodiment 2

[0038] Example 2 A hierarchical porous catalyst, the catalyst consists of 40.78g of active components and 95.15g of SiO with three-dimensional ordered hierarchical pores 2 carrier; the active ingredient consists of 35.32g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.25g NH 4 VO 3 , 0.42g Cu(CH 3 C00) 2 2H 2 O, 0.48g SbCl 3 , 0.30g H 3 AsO 4 , 1.09g H 3 PO 4 , 0.35g La(CH 3 COO) 3 1.5H 2 O, 0.45g Ce(NO 3 ) 3 ·6H 2 O and 2.12g CsOH·H 2 O composition.

[0039] Among them: SiO 2 The carrier is the same as in Example 1.

[0040] The preparation method of this hierarchical porous catalyst comprises the following steps:

[0041] (1) Weighing according to the proportion;

[0042] ⑵35.32g (NH 4 ) 6 Mo 7 o 24 4H 2 O with 0.25g NH 4 VO 3 Dissolve in 100mL deionized water to obtain soaking solution A; soaking solution B, soaking solution C, soaking solution D, and soaking solution E are the same as in Example 1;

[0043] (3) Using the equal volume impregnation method, imp...

Embodiment 3

[0045] Example 3 A hierarchical porous catalyst, the catalyst is composed of 23.12g of active components and 28.25g of SiO with three-dimensional ordered hierarchical pores 2 carrier; the active ingredient consists of 17.66g (NH 4 ) 6 Mo 7 o 24 4H 2 O, 0.25g NH 4 VO 3 , 0.42g Cu(CH 3 C00) 2 2H 2 O, 0.48g SbCl 3 , 0.30g H 3 AsO 4 , 1.09g H 3 PO 4 , 0.35g La(CH 3 COO) 3 1.5H 2 O, 0.45g Ce(NO 3 ) 3 ·6H 2 O and 2.12g CsOH·H 2 O composition.

[0046] Among them: SiO 2 The carrier is the same as in Example 1.

[0047] The preparation method of this hierarchical porous catalyst comprises the following steps:

[0048] (1) Weighing according to the proportion;

[0049] ⑵The 17.66g (NH 4 ) 6 Mo 7 o 24 4H 2 O with 0.25g NH 4 VO 3 Dissolve in 50mL deionized water to obtain soaking solution A; soaking solution B, soaking solution C, soaking solution D, and soaking solution E are the same as in Example 1;

[0050] (3) Using the equal volume impregnation metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com